Drinking water barrel cover pulling machine

A drinking water bucket and lid machine technology, which is applied in the disassembly of flanged lids, etc., can solve the problems of inability to fix empty buckets, low efficiency of removing lids, and unreasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

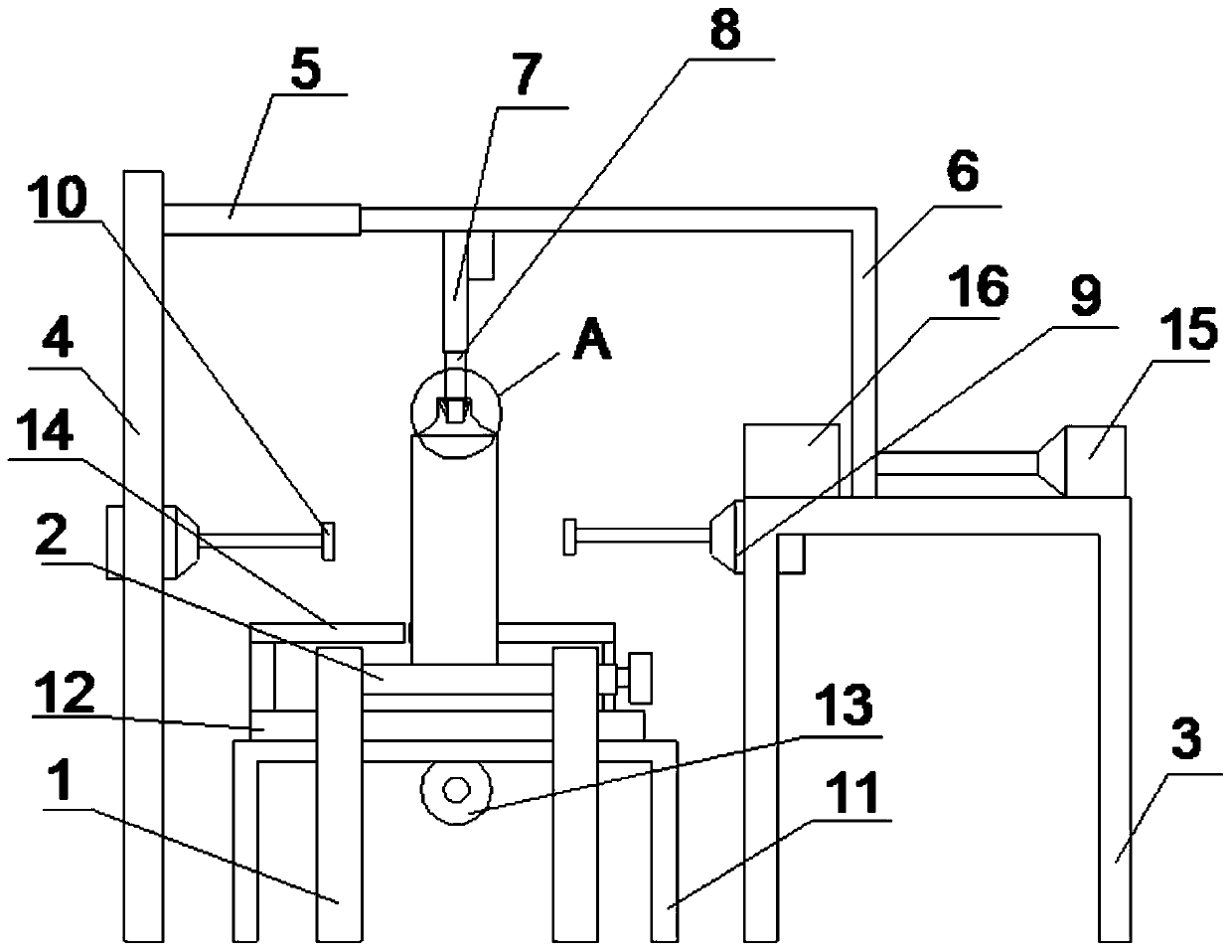

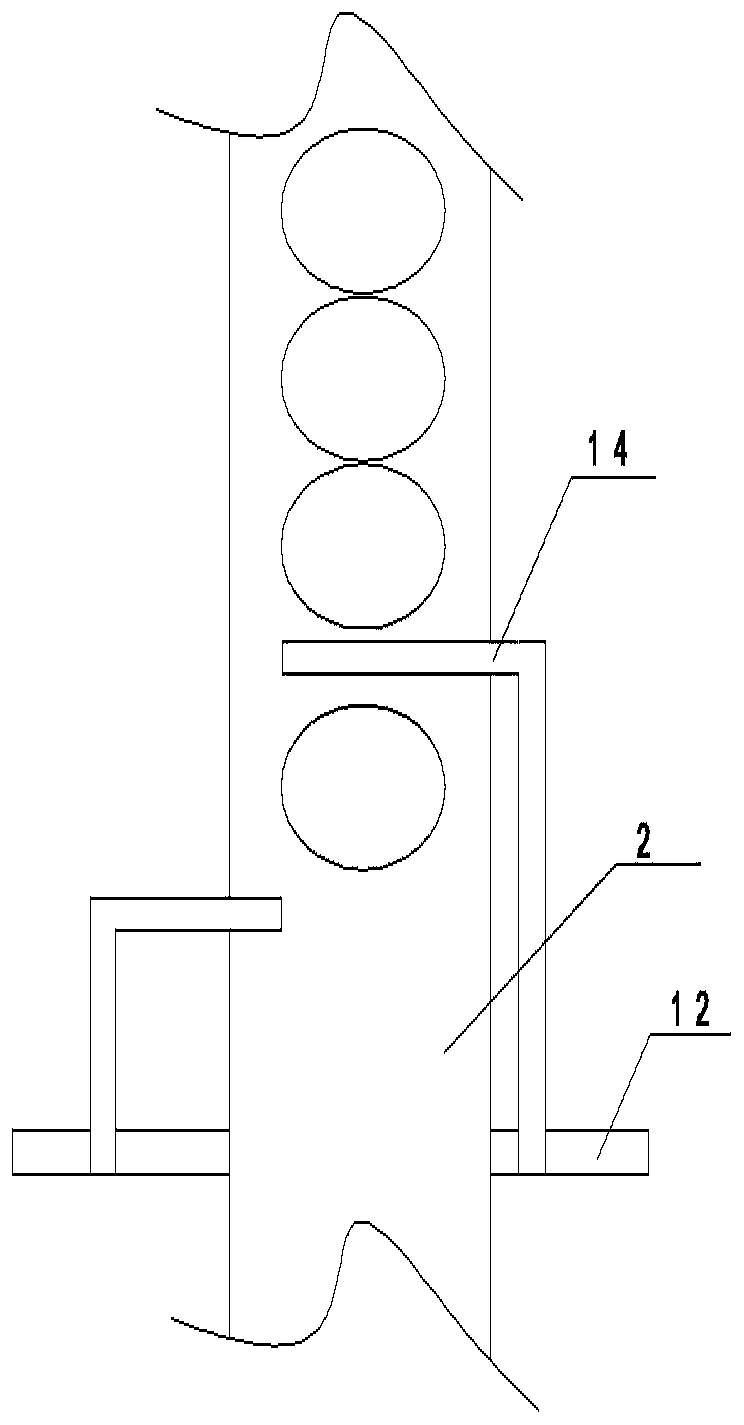

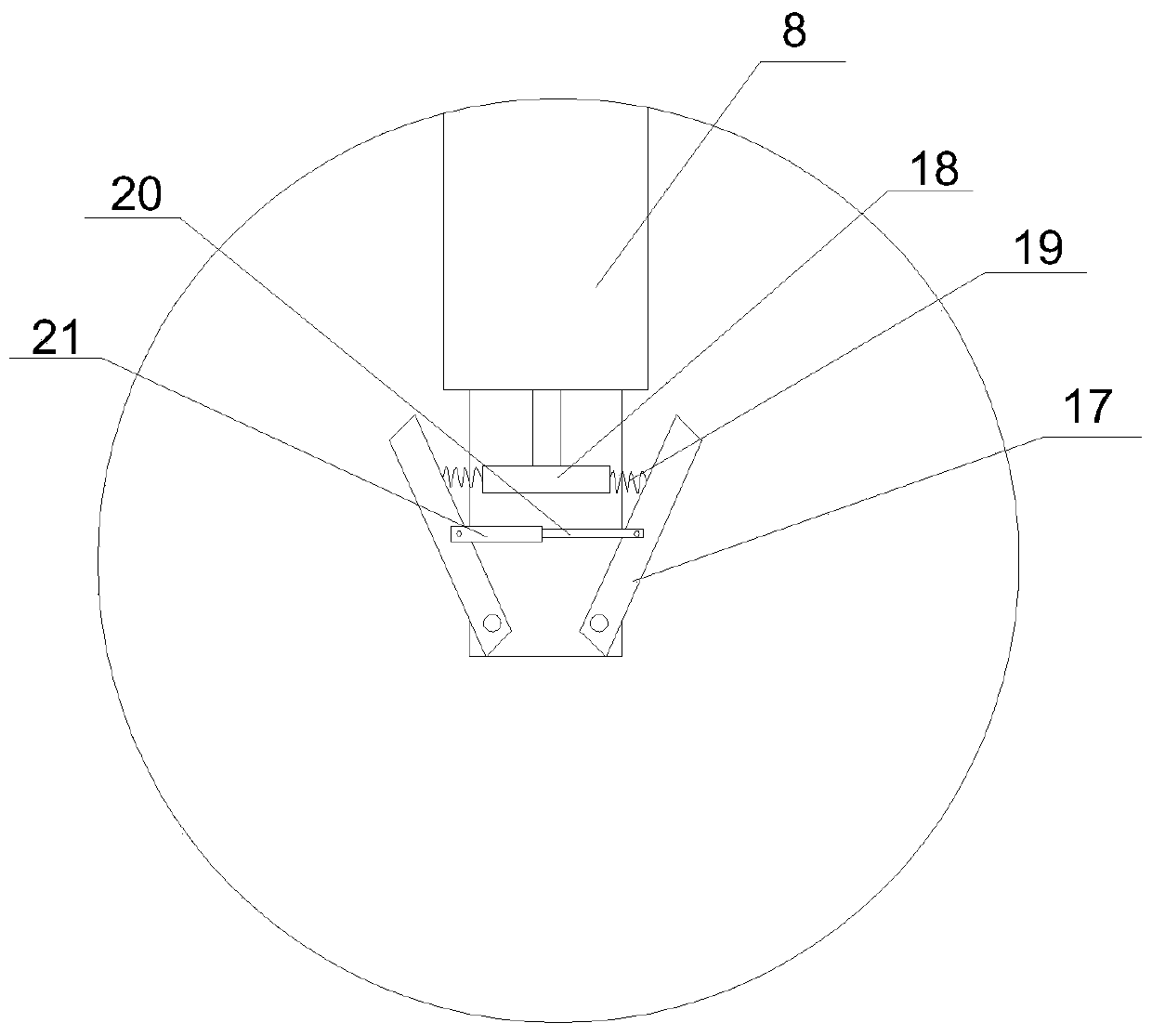

[0016] refer to Figure 1-3 , a drinking water barrel cap removal machine, comprising a frame 1, the frame 1 is provided with a conveyor belt 2 along the front and rear directions, a support frame 3 is provided on one side of the frame 1, and a support frame 3 is provided on the other side of the frame 1 The column 4 opposite to the frame 3, the upper end of the column 4 is horizontally provided with a positioning cylinder 5, and the top of the support frame 3 is vertically provided with an inverted L-shaped fixed rod 6, and the horizontal part of the inverted L-shaped fixed rod 6 can be inserted into the positioning cylinder 5, and the inverted L The bottom end of the horizontal part of the type fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com