Antibacterial ABS resin

A technology of ABS resin and compound antibacterial agent, applied in the field of antibacterial ABS resin, can solve the problems of poor sterilization effect, achieve the effect of improving sterilization effect and reducing photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

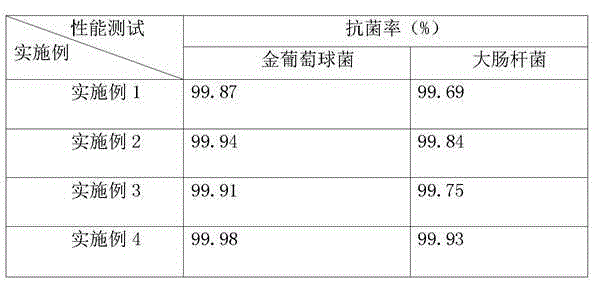

Examples

Embodiment 1

[0020] An antibacterial ABS resin, comprising the following components by weight: 100 parts of ABS, 0.2 parts of a composite antibacterial agent; the composite antibacterial agent is composed of the following components: zeolite powder, nano-titanium dioxide, nano-silver oxide, polyhexamethylene guanidine phosphate.

[0021] The composite antibacterial agent is composed of the following components by weight: 13 parts of zeolite powder, 10 parts of nano-titanium dioxide, 10 parts of nano-silver oxide, and 15 parts of polyhexamethylene guanidine phosphate.

[0022] Wherein the ABS plastic masterbatch is ABSHI100Y produced by LG Chemical Company, the average particle diameter of nano-titanium dioxide and nano-silver oxide is 10 nm, and the particle size of zeolite powder is 0.2 μm.

[0023] A kind of preparation method of above-mentioned antibacterial ABS resin, comprises the following steps:

[0024] a. Mix and stir the zeolite powder and nano-titanium dioxide, stir and mix for...

Embodiment 2

[0029] An antibacterial ABS resin, comprising the following components by weight: 100 parts of ABS, 0.3 parts of a composite antibacterial agent; the composite antibacterial agent is composed of the following components: zeolite powder, nano-titanium dioxide, nano-silver oxide, polyhexamethylene guanidine phosphate.

[0030] The composite antibacterial agent is composed of the following components by weight: 13 parts of zeolite powder, 10 parts of nano-titanium dioxide, 10 parts of nano-silver oxide, and 15 parts of polyhexamethylene guanidine phosphate.

[0031] Wherein the ABS plastic masterbatch is ABSHI100Y produced by LG Chemical Company, the average particle diameter of nano-titanium dioxide and nano-silver oxide is 10 nm, and the particle size of zeolite powder is 0.2 μm.

[0032] A kind of preparation method of above-mentioned antibacterial ABS resin, comprises the following steps:

[0033] a. Mix and stir the zeolite powder and nano-titanium dioxide, stir and mix for...

Embodiment 3

[0038] An antibacterial ABS resin, comprising the following components by weight: 100 parts of ABS, 0.3 parts of a composite antibacterial agent; the composite antibacterial agent is composed of the following components: zeolite powder, nano-titanium dioxide, nano-silver oxide, polyhexamethylene guanidine phosphate.

[0039] The composite antibacterial agent is composed of the following components by weight: 13 parts of zeolite powder, 10 parts of nano-titanium dioxide, 10 parts of nano-silver oxide, and 15 parts of polyhexamethylene guanidine phosphate.

[0040] Wherein the ABS plastic masterbatch is ABSHI100Y produced by LG Chemical Company, the average particle diameter of nano-titanium dioxide and nano-silver oxide is 10 nm, and the particle size of zeolite powder is 0.2 μm.

[0041] A kind of preparation method of above-mentioned antibacterial ABS resin, comprises the following steps:

[0042] a. Mix and stir the zeolite powder and nano-titanium dioxide, stir and mix for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com