Production method of high-efficiency herbicide furazone

A production method, the technology of furazone, which is applied in the production field of the high-efficiency herbicide furazone, can solve the problems of hidden dangers in production safety, inapplicability to industrial production, and difficult operation, and achieve low requirements for reaction purification conditions, which are conducive to wide application, The effect of not being easy to discharge waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

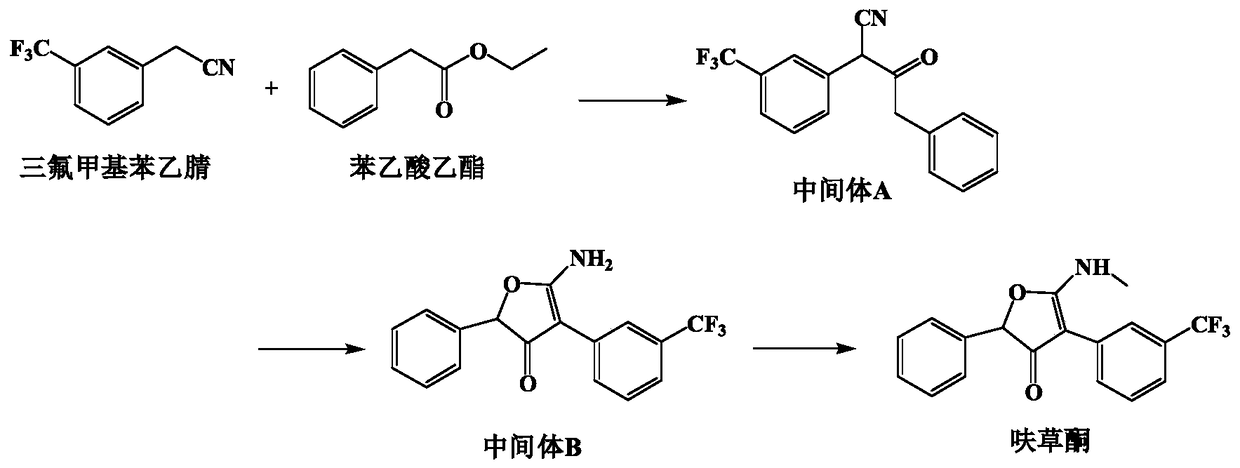

[0023] The first step: add 100L of methanol solvent into the reactor, and dissolve 58.4Kg of sodium methoxide in the above-mentioned solvent, slowly add 100Kg of m-trifluoromethylphenylacetonitrile and 115Kg of ethyl phenylacetate mixed solution into it under full stirring, and add the After completion, the reaction was stirred at 25° C. for 16 hours, 250 L of water was added to the mixed liquid, the pH was adjusted to 1 with hydrochloric acid, and then extracted with dichloroethane and concentrated to dryness to obtain intermediate product A.

[0024] The second step: the above-mentioned intermediate product A was dissolved in 200L of methanol, and then 82.1Kg of liquid bromine was slowly added to the above-mentioned solution and stirred at room temperature for 13 hours. After the reaction, sodium sulfite was added to react the excess bromine. Add 200L of water to the mixture, and then extract it three times with dichloroethane to obtain the dichloroethane extract containing t...

Embodiment 2

[0027] The first step: add 100L of methanol solvent into the reactor, and dissolve 73.5Kg of sodium ethoxide in the above-mentioned solvent, and slowly add 100Kg of m-trifluoromethylphenylacetonitrile and 105Kg of ethyl phenylacetate mixture to it under full stirring, and add the After completion, the reaction was stirred at 25° C. for 18 hours, 250 L of water was added to the mixture, the pH was adjusted to 3 with hydrochloric acid, and then extracted with dichloroethane and concentrated to dryness to obtain intermediate product A.

[0028] The second step: the above-mentioned intermediate product A was dissolved in 200L of methanol, and then 80.8Kg of liquid bromine was slowly added to the above-mentioned solution and stirred at room temperature for 13 hours. After the reaction, sodium sulfite was added to react excess bromine. Add 200L of water to the mixture, and then extract it three times with dichloroethane to obtain the dichloroethane extract containing the intermediate...

Embodiment 3

[0031] The first step: Add 100L of methanol solvent into the reactor, and dissolve 93.4Kg of sodium tert-butoxide in the above solvent, and slowly add 100Kg of m-trifluoromethyl phenylacetonitrile and 106Kg of ethyl phenylacetate mixture into it under full stirring , after the addition, stirred and reacted at 25° C. for 15 hours, added 250 L of water to the mixture, adjusted the pH to 3 with hydrochloric acid, extracted with dichloroethane, concentrated to dryness to obtain intermediate product A.

[0032] The second step: the above intermediate product A was dissolved in methanol 200L methanol, then 81.6Kg liquid bromine was slowly added to the above solution and stirred at room temperature for 13 hours, after the reaction was completed, sodium sulfite was added to react excess bromine. Add 200L of water to the mixture, and then extract it three times with dichloroethane to obtain the dichloroethane extract containing the intermediate product B, and put this solution directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com