Extractive distillation method of tert-butyl alcohol-propyl formate azeotropic mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

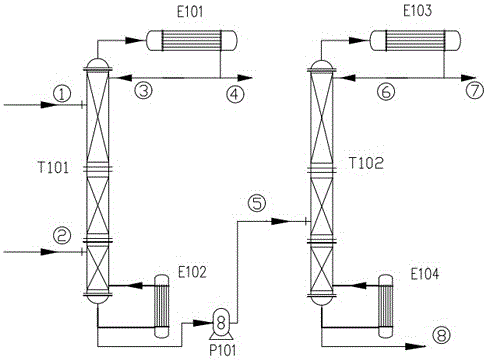

[0047] This implementation case is a continuous extraction and distillation operation mode, as attached image 3 As shown, ethylene glycol and N-ethylpyridinium phosphate dimethyl salt ([epy][DMP]) were selected as the extractant, and the dosage was 300kg / h; %) and propyl formate (60wt%). The number of T101 trays is 55, the feeding position of the extractant is on the 5th tray, and the feeding position of the raw material is on the 45th tray. The reflux ratio is set at 5:1, the extraction rate at the top of the tower is 60kg / h, and the purity of the obtained propyl formate is 99.7%. The number of trays in T102 is 15, the feeding position of stream ⑤ is the seventh tray, the reflux ratio is 0.5:1, the extraction rate at the top of the tower is 40kg / h, and the purity of tert-butanol obtained is 99.6%. The extraction agent at the bottom of the column is refluxed as a supplement to the solvent.

Embodiment 2

[0049] The extraction agent is ethylene glycol, the dosage is 300kg / hr, the reflux ratio of T101 is set to 5.5:1, the reflux ratio of T102 is set to 0.6:1, other conditions are as in Example 1. The purity of the obtained tert-butanol and propyl formate products are both above 99.9%.

Embodiment 4

[0051] This implementation case is an operation mode of batch extraction and rectification, as attached Figure 4 As shown, ethylene glycol and N-methylpyridine phosphate dimethyl salt ([mpy][DMP]) were selected as the extractant, and the dosage was 500kg; the raw material processing capacity was 100kg, and the raw material composition was tert-butanol (40wt%) and formic acid Propyl ester (60wt%); the number of theoretical plates is 60, and the feeding position of the extractant is on the fifth plate. The mixture of tert-butanol and propyl formate is injected into the distillation column E1 by the raw material pump P2 at one time, and the heating is started; when the condensate appears at the top of the column, the total reflux operation is carried out, and the extractant is continuously added into the column through the pump P1, and Continue the total reflux operation; when the temperature at the top of the tower reaches 55°C, it is detected that the content of propyl formate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com