Preparation method for polished-crystal crackled glaze tile

A technology of cracked glaze and polished crystal bricks is applied in the field of preparation of cracked glazed tiles of polished crystal tiles. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

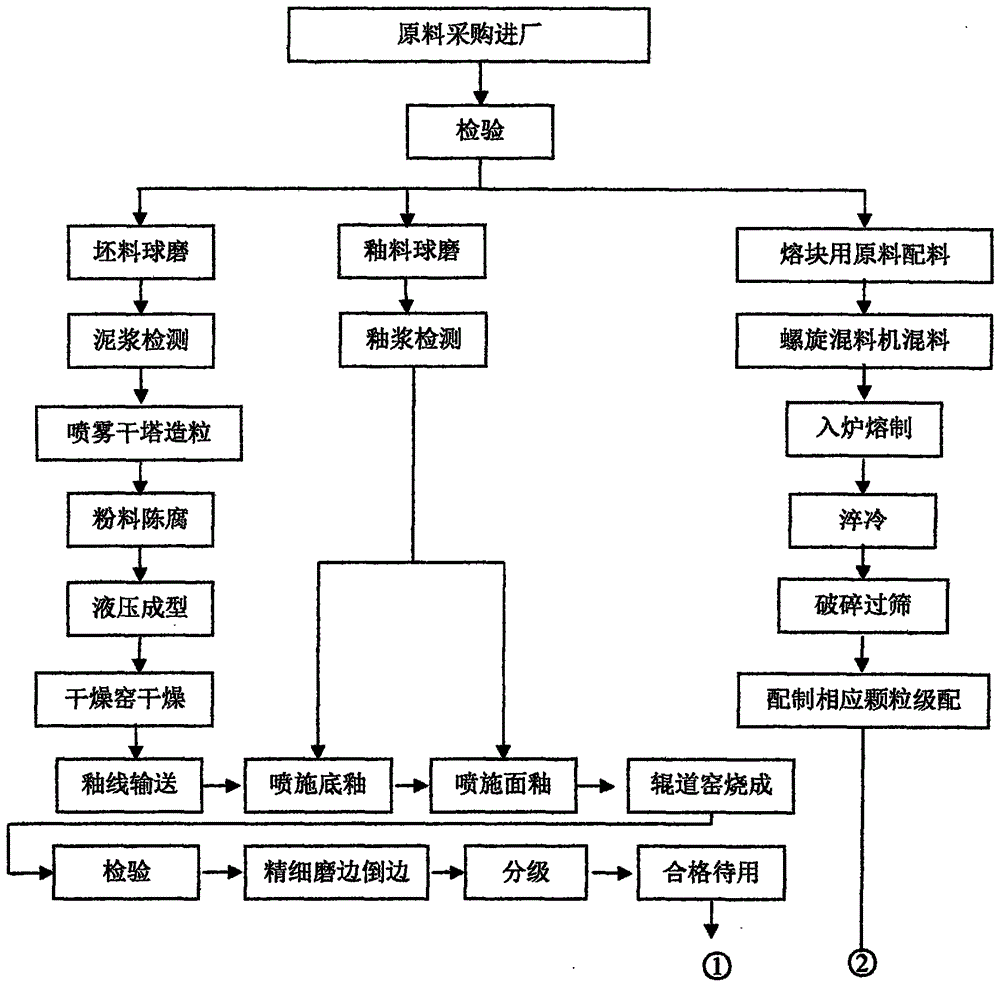

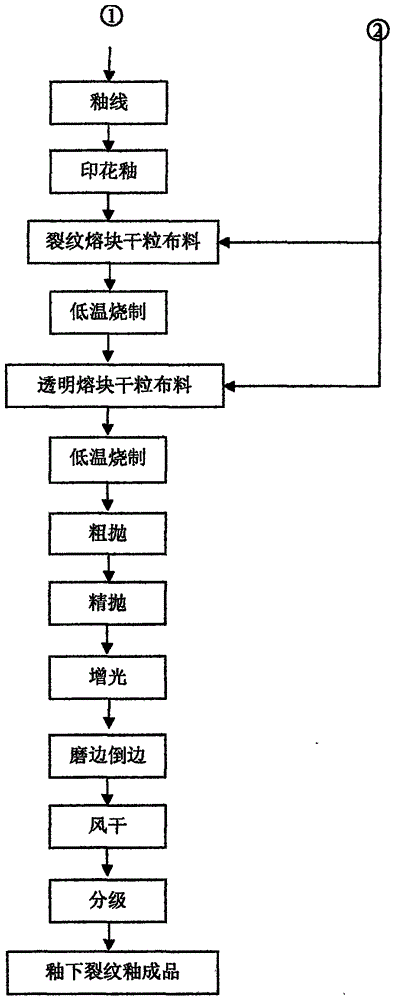

Method used

Image

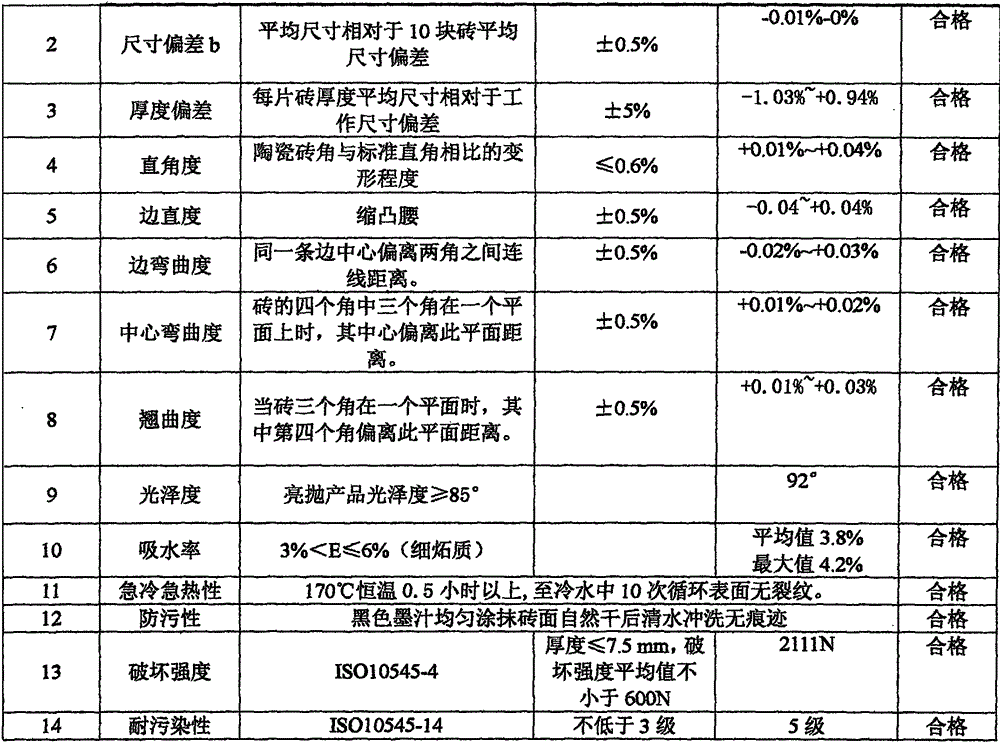

Examples

Embodiment 1

[0030] 1 Ceramic green body preparation:

[0031] 1.1 Mineral composition of raw material for billet:

[0032] Porcelain sand (high temperature sand, medium temperature, low temperature sand, potassium sand), clay (black mud, kaolin), talc, etc.

[0033] 1.2 The chemical composition of the billet raw materials:

[0034] SiO 2 67.02%, Al 2 o 3 19.82%, CaO+MgO3.11%, K 2 O+Na 2 O5.37%, Fe 2 o 3 0.64%, TiO 2 0.21%, loss on ignition (IL) 3.83%

[0035] 1.3 Blank powder preparation:

[0036] According to the blank formula, add appropriate amount of water for every 40T kg of grinding, add 0.3-0.5% water glass and sodium tripolyphosphate as water reducer, input the ball mill into the slurry with 0.5-1% fineness and 10,000-hole sieve, and then spray Dry powder, spray dry powder with a moisture content of 6.0-7.0%, stale for 36 hours and wait for moisture balance;

[0037] 1.4 After being hydroformed by a 30Mpa pressure automatic hydraulic press, the specifications of 330*33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com