A low-pressure fan abrasive injection device and its application method

A low-pressure fan and jetting device technology, applied in abrasive feeding device, used abrasive processing device, abrasive and other directions, can solve the problems of high raw material cost, complex equipment structure, high process energy consumption, and achieve structural size design Reasonable, low abrasive crushing rate, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

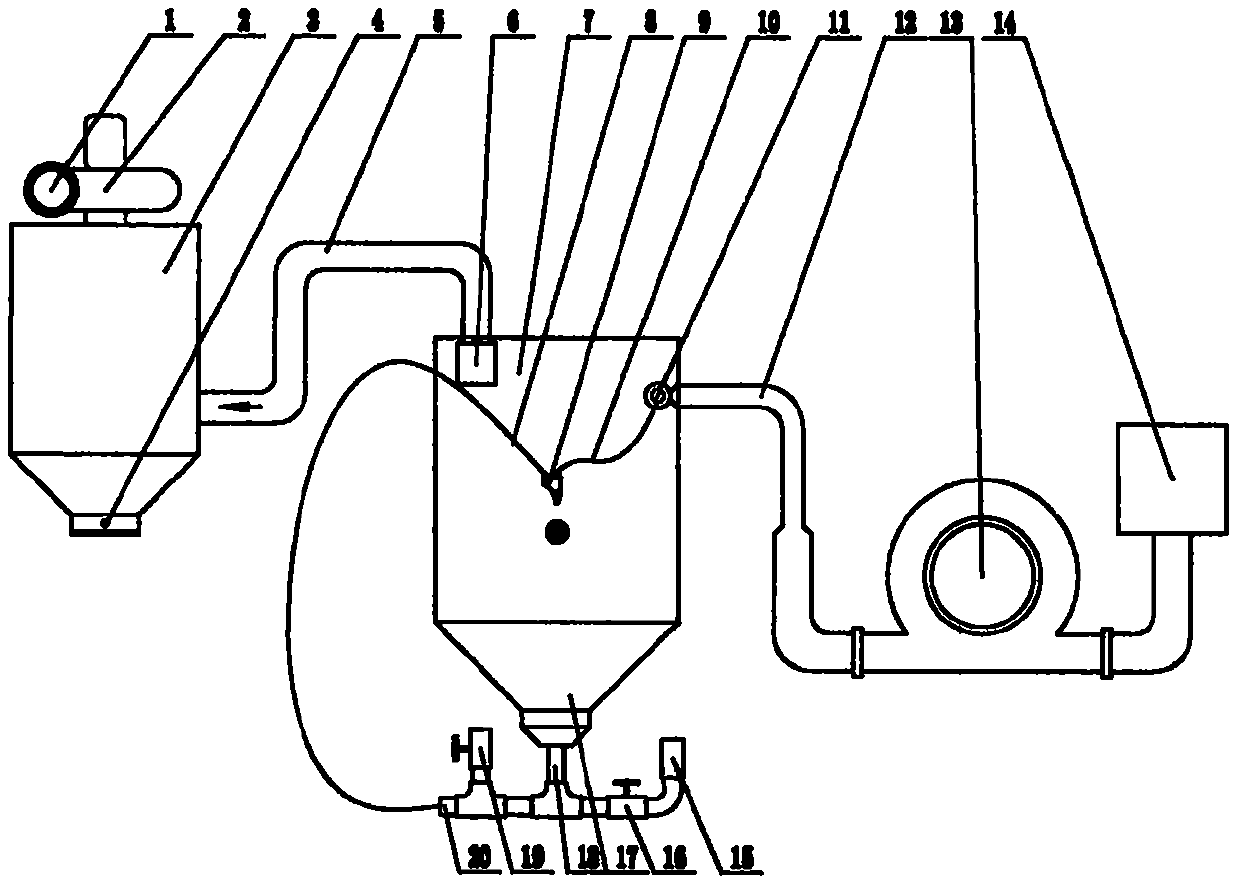

[0030] Attached below figure 1 The structure and usage method of the abrasive blasting device of the present invention will be described. A low-pressure blower abrasive injection device is provided with a dust remover, a working chamber, an abrasive supply device, an abrasive collector and an air supply device, the air supply device is a low-pressure blower fan 13, and a nozzle 9 is arranged in the working chamber 7. Spray head one end is provided with nozzle, and the other end communicates with air inlet pipe 10 and inlet abrasive material pipe 8, and the top of working chamber communicates with described deduster, and the bottom of working chamber communicates with described abrasive material collector 17, and described air inlet pipe communicates with described dust catcher. The low-pressure blower is communicated, and the abrasive material inlet pipe is communicated with the abrasive material supplier; the abrasive material supplier is communicated with the abrasive materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com