An adjustable dual-function spindle loose broach control device

A control device, dual-function technology, applied in positioning devices, manufacturing tools, clamping and other directions, can solve the problems of not being suitable for spindle testing of various sizes and specifications, and not having the function of loosening and broaching spindle testing, saving time, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

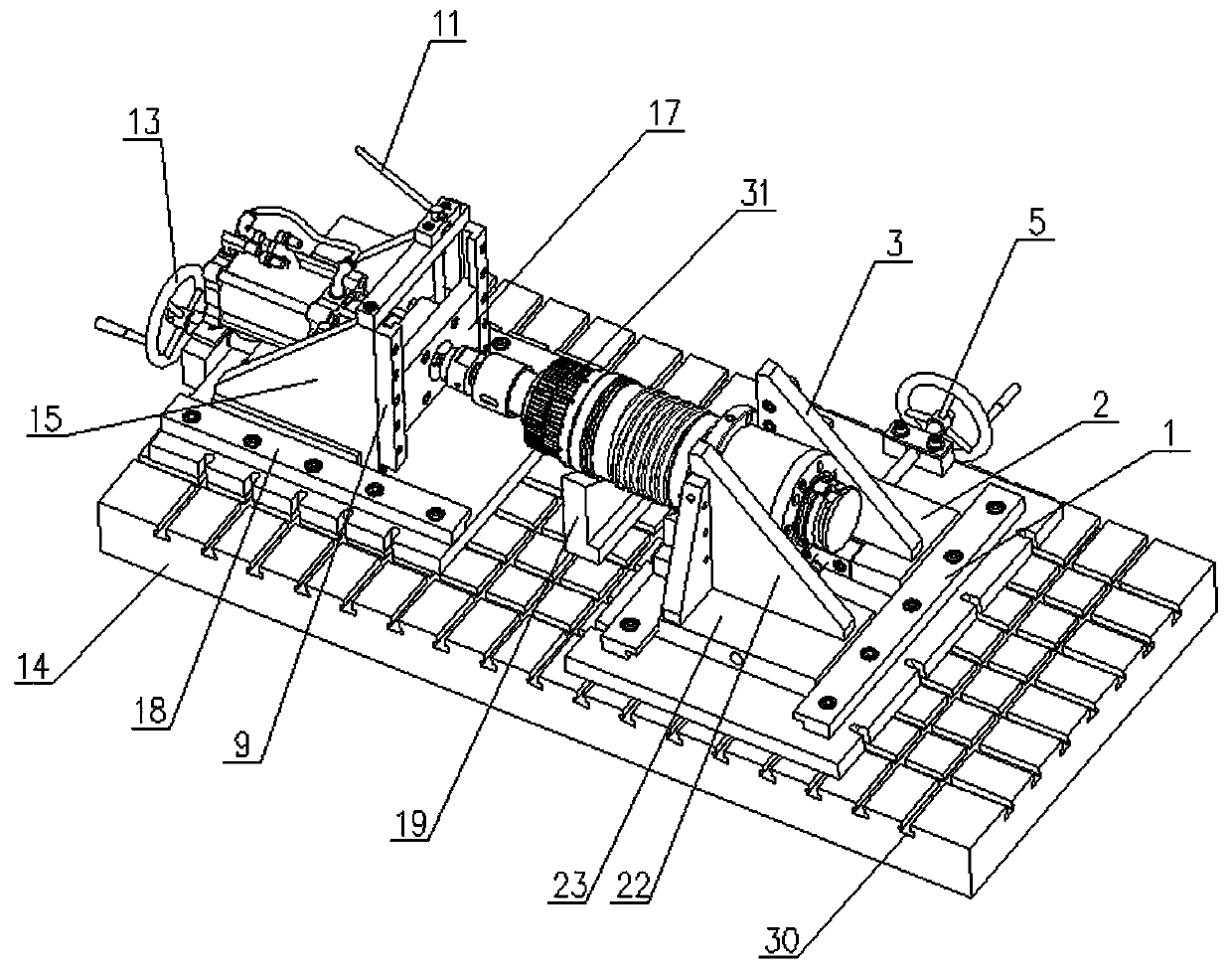

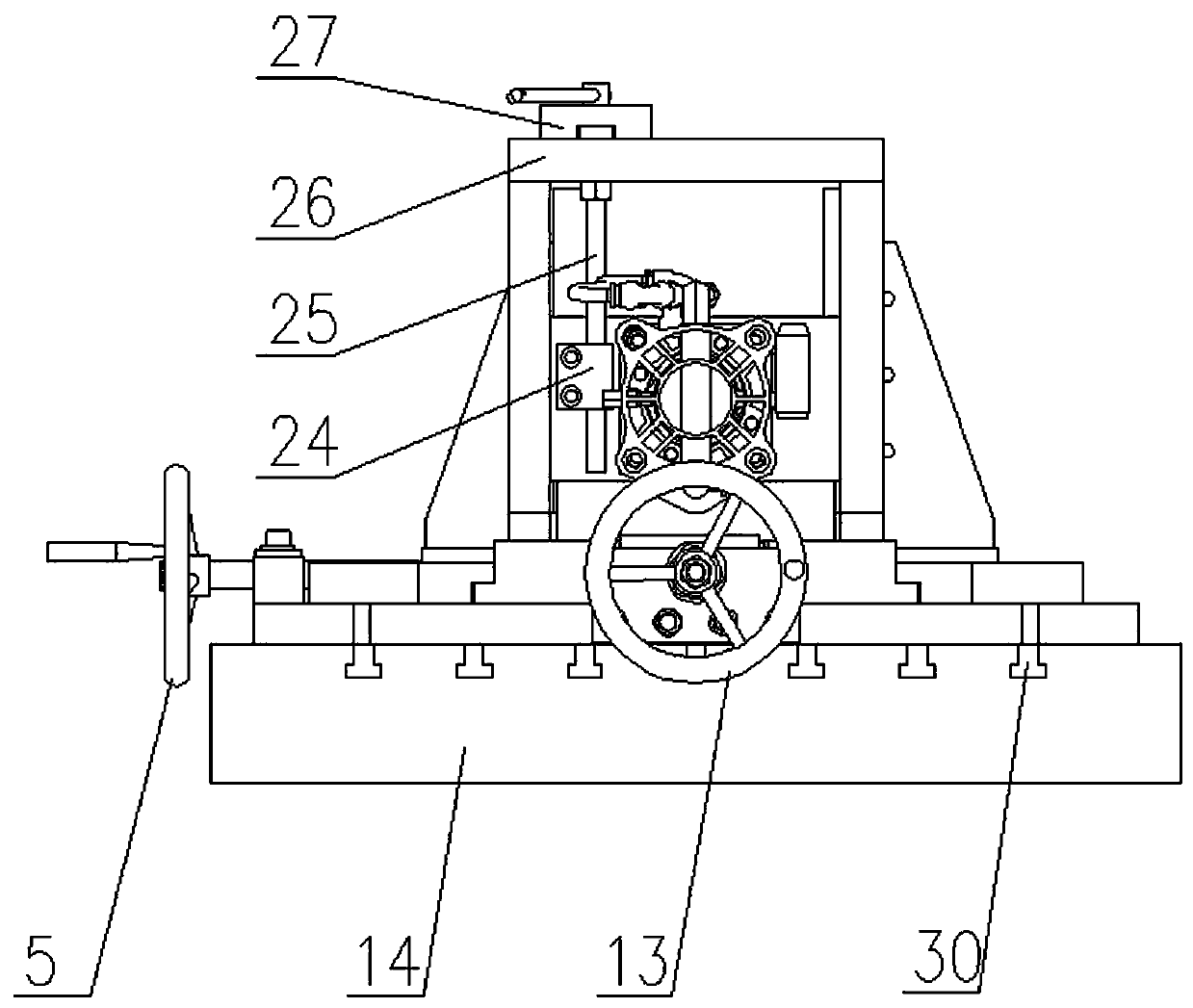

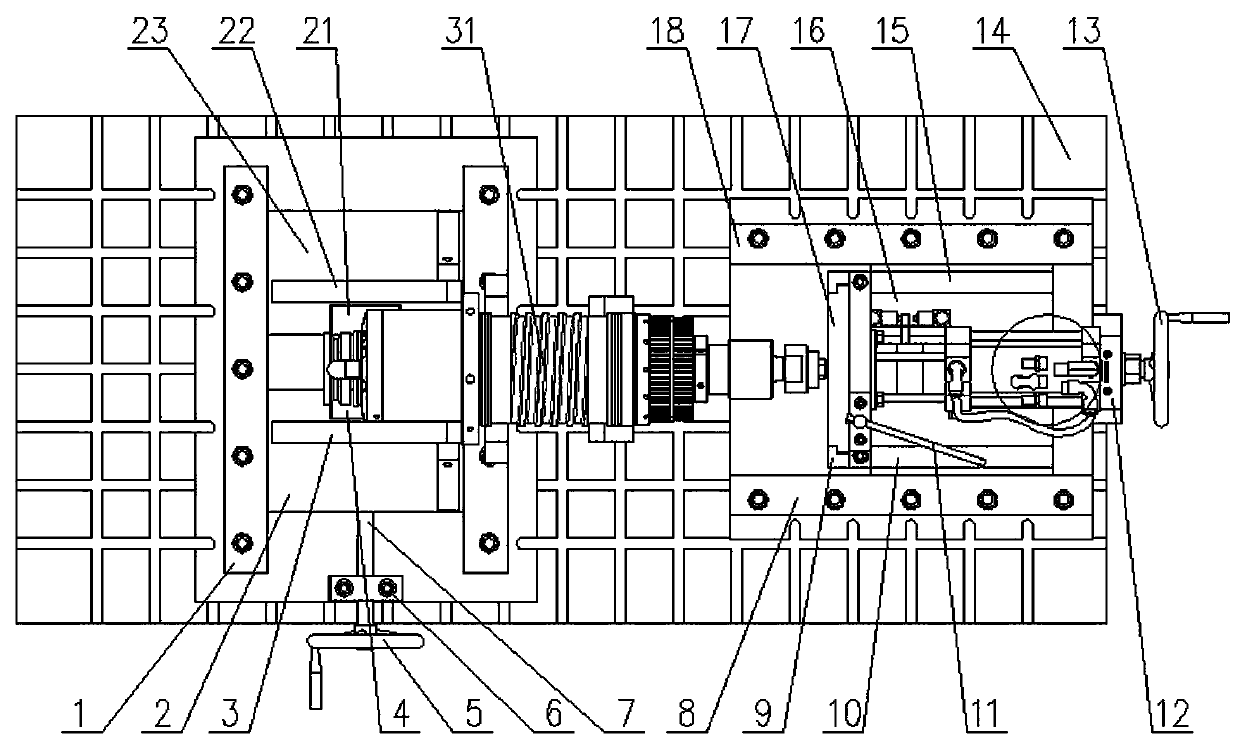

[0026] The present invention will be further elaborated below in combination with specific embodiments.

[0027] As shown in the figure: an adjustable dual-function spindle loose broach control device, including the spindle support of the machining center and the knife cylinder support fixed on the base platform 14 by bolts, it is characterized in that: the base platform 14 A plurality of equidistant T-slots 30 are arranged horizontally and vertically, and the bottoms of the spindle support of the machining center and the tool cylinder support are respectively provided with protrusions that match the T-slots 30, and can fit inside the T-slots 30. Sliding to adjust the relative position between the spindle support of the machining center and the tool cylinder support; the spindle support of the machining center is provided with a transverse guide rail, a transverse slider and a fixed spindle rib plate to radially position the spindles to be processed with different diameters , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com