Fluid impact fatigue fracture deburring device and deburring method

An impact fatigue and deburring technology, applied in the field of deburring, can solve problems such as poor processing of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0085] The fluid impact fatigue fracture deburring device of the present invention is used to remove the horizontal hole burrs generated in the production process of the automobile brake master cylinder 37, and improve the processing efficiency and processing quality of the automobile brake master cylinder 37.

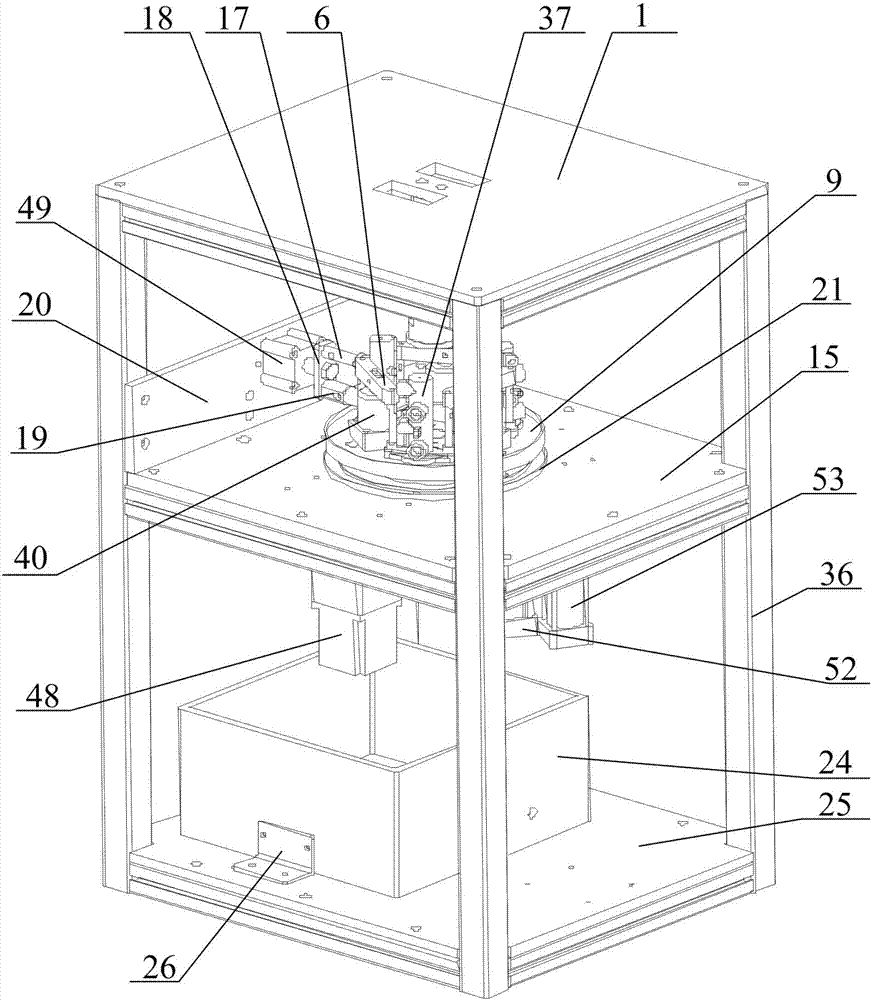

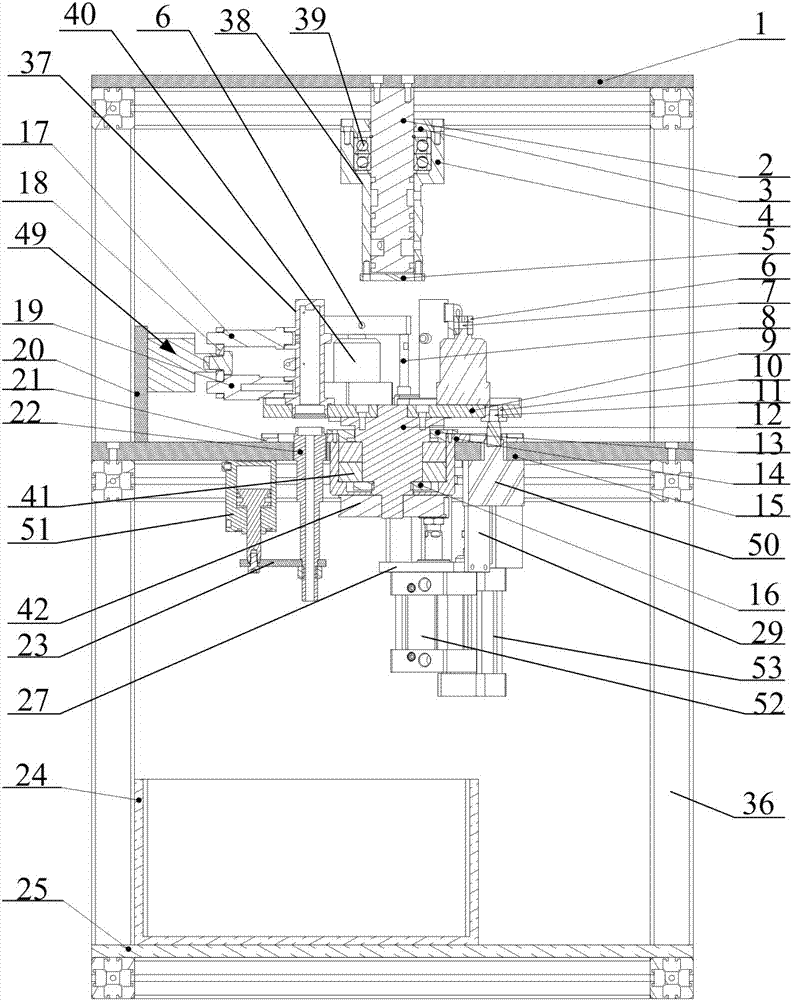

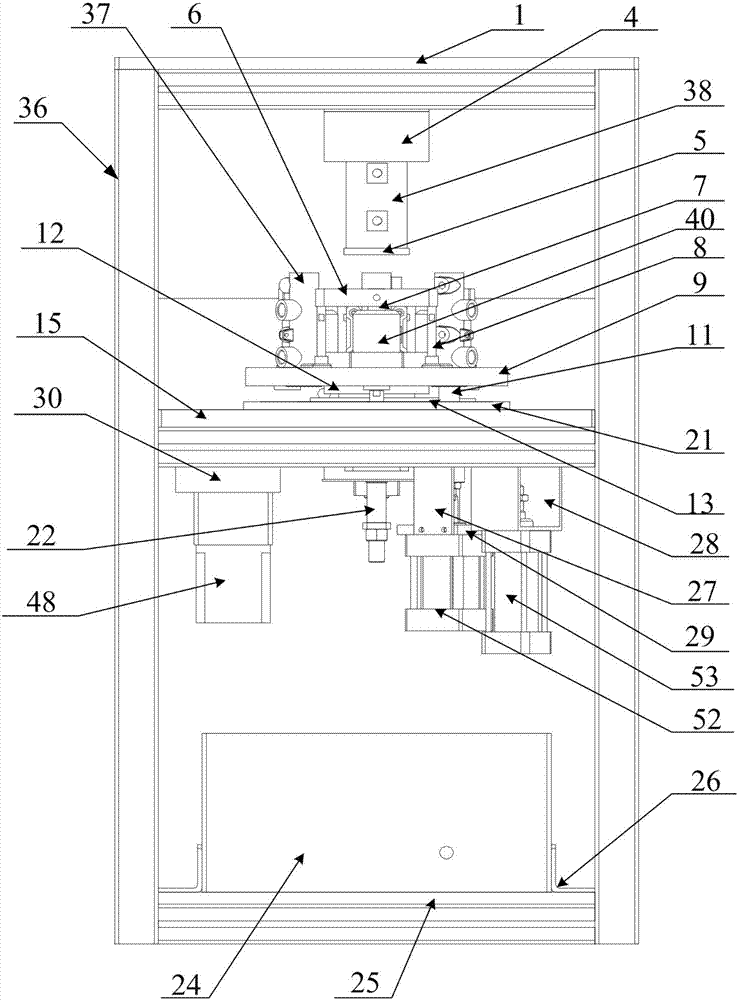

[0086] like figure 1 , figure 2 and image 3 As shown, the fluid impact fatigue fracture deburring device of the present invention has a frame structure as a whole, and its main structure is installed inside the frame structure. , a frame 36, wherein the frame 36 is built by 50X50 aluminum profiles and casters are installed, the frame 36 mainly includes four vertical beams, the first fixing plate 1 is fixed on the upper ends of the four vertical beams, and the oil tank fixing plate 25 is fixed on the four vertical beams. Beam lower end, support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com