Beneficiation method for recovering pyrites from coal gangue

A mineral processing method and coal gangue technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of poor flotation selectivity, complexity, pyrite loss, etc., to improve the recovery rate, increase Effect of added value and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

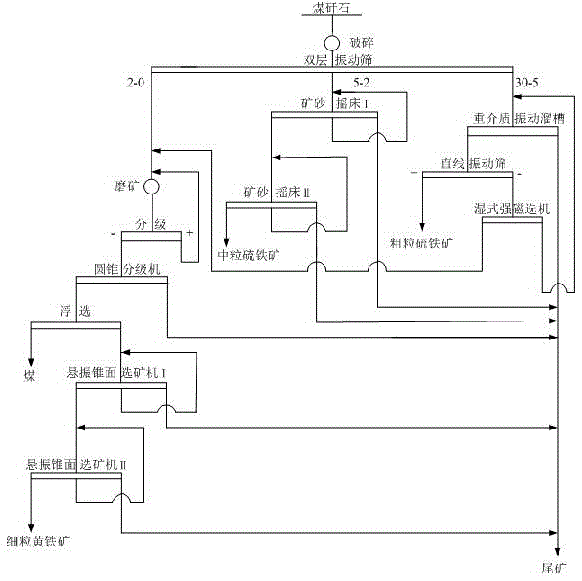

[0023] Example 1: figure 1 As shown, the mineral processing method of reclaiming pyrite from coal gangue adopts the following specific process steps.

[0024] (1) Coal gangue passes through a double-layer vibrating screen after a crushing operation, and the coarse-grained products of 30-5 mm are sorted through a dense medium vibrating chute, and the gangue minerals are used as tailings; the concentrate products are de-mediumed through a linear vibrating screen , the product on the sieve is coarse-grained pyrite, and the product under the sieve is subjected to strong magnetic separation by a wet-type high-strength magnetic separator, the magnetic product is returned to the heavy medium vibrating chute, and the non-magnetic product is fed into the grinding operation of step (3); Among them, the magnetic field strength of the wet strong magnetic separator is 480KA / m, the pulse stroke is 25mm, the pulse frequency is 310 times / min, and the pulp mass concentration is 28%.

[0025] ...

Embodiment 2

[0029] Embodiment 2: This mineral processing method for recovering pyrite from coal gangue adopts the following specific process steps.

[0030] (1) Coal gangue passes through a double-layer vibrating screen after a crushing operation, and the coarse-grained products of 30-5 mm are sorted through a dense medium vibrating chute, and the gangue minerals are used as tailings; the concentrate products are de-mediumed through a linear vibrating screen , the product on the sieve is coarse-grained pyrite, and the product under the sieve is subjected to strong magnetic separation by a wet-type high-strength magnetic separator, the magnetic product is returned to the heavy medium vibrating chute, and the non-magnetic product is fed into the grinding operation of step (3); Among them, the magnetic field strength of the wet strong magnetic separator is 520KA / m, the pulse stroke is 27mm, the pulse frequency is 330 times / min, and the pulp mass concentration is 30%.

[0031] (2) The medium-...

Embodiment 3

[0035] Embodiment 3: This mineral processing method for recovering pyrite from coal gangue adopts the following specific process steps.

[0036] Except following difference, all the other processes are with embodiment 1:

[0037] In step (1): the magnetic field strength of the wet strong magnetic separator is 450KA / m, the pulse stroke is 26mm, the pulse frequency is 350 times / min, and the pulp mass concentration is 35%.

[0038] In step (3): the overflow particle size of the classification equipment is -0.074mm, accounting for 80%; the rotation speed of the sorting surface of the suspension vibrating cone concentrator I is 1.3r / min, the vibration frequency of the disk surface is 400 times / min, and the washing water Velocity is 1.0m 3 / h, the ore feeding rate is 0.32t / h, the pulp mass concentration is 15%; the rotation speed of the sorting surface of the suspension vibrating cone concentrator II is 1.3r / min, the vibration frequency of the disk surface is 350 times / min, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com