Preparation method of visible light excitation antibacterial coating layer containing nano cuprous oxide

A nano-cuprous oxide, antibacterial coating technology, applied in the fields of botanical equipment and methods, preservation of human or animal bodies, chemicals for biological control, etc., can solve problems such as eye hazards in the central nervous system, and achieve Efficient bactericidal properties and enhanced antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

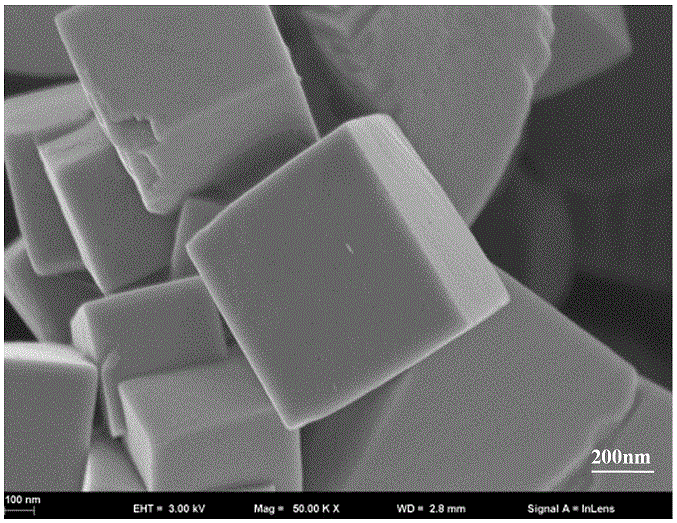

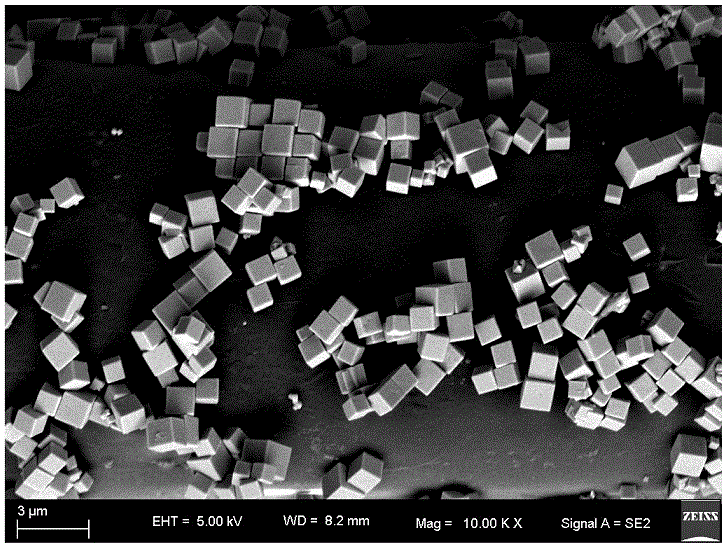

[0046] Preparation of nano Cu2O (cuprous oxide):

[0047] (a) Dissolve 2mmol CuSO4·5H2O and 1mmol EDTA (ethylenediaminetetraacetic acid) in 30mL deionized water, and stir for 30min;

[0048] (b) Heat the solution prepared in step a to 55°C, and add 25mL of 0.6M NaOH solution;

[0049] (c) After 5 minutes, add 0.5 g of C6H6O2 (1,4-hydroquinone) to the solution prepared in step b, and continue stirring for 1 hour;

[0050] (d) After the reaction in step c, the solution was naturally cooled to room temperature, and then the precipitate was centrifuged (8000rpm, 5min), washed with deionized water and absolute ethanol, and then dried to obtain nano Cu2O.

Embodiment 2

[0052] Preparation of Nanometer Cu2O-Ag

[0053] (a) Dissolve 2mmol CuSO4·5H2O, 1mmol EDTA (ethylenediaminetetraacetic acid) and AgNO3 (the molar ratio of Ag+ to Cu2+ is 1%-100%) in 30mL deionized water, and stir for 30min;

[0054] (b) Heat the solution prepared in step a to 55°C, and add 25mL of 0.6M NaOH solution;

[0055] (c) After 5 minutes, add 0.5 g of C6H6O2 (1,4-hydroquinone) to the solution prepared in step b, and continue stirring for 1 hour;

[0056] (d) After the reaction in step c, the solution was naturally cooled to room temperature, and then the precipitate was centrifuged (8000rpm, 5min), washed with deionized water and absolute ethanol, and then dried to obtain nano Cu2O-Ag.

Embodiment 3

[0058] Preparation of Nanometer Cu2O-ZnO

[0059] (a) Dissolve 2mmol CuSO4·5H2O, 1mmol EDTA (ethylenediaminetetraacetic acid) and Zn(CH3COO)2 (the molar ratio of Zn+ to Cu2+ is 1%-100%) in 30mL deionized water, and stir for 30min;

[0060] (b) Heat the solution prepared in step a to 55°C, and add 25mL of NH3·H2O solution;

[0061] (c) After 5 minutes, add 0.5 g of C6H6O2 (1,4-hydroquinone) to the solution prepared in step b, and continue stirring for 1 hour;

[0062] (d) After the reaction in step c, the solution was naturally cooled to room temperature, and then the precipitate was centrifuged (8000rpm, 5min), washed with deionized water and absolute ethanol, and then dried to obtain nano Cu2O-ZnO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com