Positive pole lead paste of lead acid battery and paste blending method thereof

A lead-acid battery, positive lead paste technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of energy consumption, difficulty in ensuring 4BS content, etc., and achieve the effect of increasing the temperature of lead powder and prolonging the mixing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 1000kg of lead powder, the amount of dilute sulfuric acid with a density of 1.4g / ml is 80L, and the amount of water added to 1kg of polyester is 110Kg;

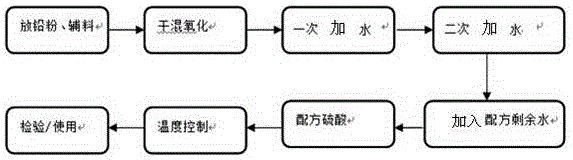

[0038] figure 1 It is a flow chart of the method for blending the positive electrode paste of a lead-acid storage battery of the present invention. As shown in the figure, the method for blending the positive electrode paste of the present invention is prepared by the following steps:

[0039] (1) Put the lead powder and fiber into the paste machine for dry mixing;

[0040] (2) Add water and stir for the first time; add water and stir for the first time, the amount of water added is 25Kg of lead powder, and the stirring time is 6 minutes;

[0041] (3) Add water and stir again; add water and stir again, the amount of water added is 10Kg of lead powder, and the stirring time is 4min;

[0042] (4) Quickly add the remaining 75Kg of water and stir, the time for adding water is 2 minutes, and the stirring time is 1 m...

Embodiment 2

[0048] Weigh 1000kg of lead powder, the amount of dilute sulfuric acid with a density of 1.4g / ml is 90L, and the amount of water added to 1.5kg of nylon is 100Kg; the following steps are used to prepare:

[0049] (1) Put the lead powder and fiber into the paste machine for dry mixing;

[0050] (2) Add water and stir for the first time; add water and stir for the first time, the amount of water added is 20Kg of lead powder, and the stirring time is 6 minutes;

[0051] (3) Add water and stir again; add water and stir again, the amount of water added is 10Kg of lead powder, and the stirring time is 4min;

[0052] (4) Quickly add the remaining 70Kg of water and stir, the time for adding the remaining water is 2 minutes, and the stirring time is 1 minute;

[0053] (5) Add dilute sulfuric acid and continue stirring until the temperature rises to 75°C, turn on the circulating water to cool down; the time for adding dilute sulfuric acid is 13 minutes;

[0054] (6) Turn off the circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com