Remote monitoring system for chlorine dioxide generation device based on cloud platform

A remote monitoring system, chlorine dioxide technology, applied in the general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problem of water quality stability and safety, water without disinfection and sterilization exceeding the standard, equipment Supervision is not easy to put in place and other problems, to achieve the effect of convenient after-sales service, saving manpower and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

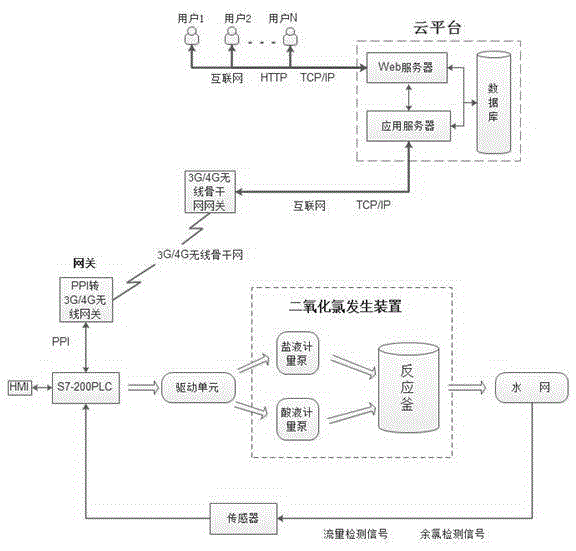

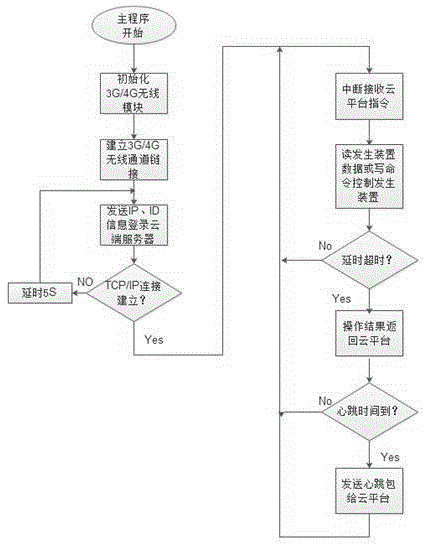

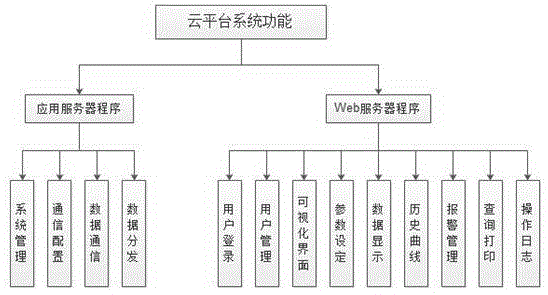

[0017] In order to achieve the purpose of the present invention, the present invention adopts the following technical solutions: a remote monitoring system of chlorine dioxide generator based on 3G / 4G wireless network and cloud platform, including cloud platform, 3G / 4G wireless network, PPI-3G / 4G wireless network gateway, PLC, HMI, drive unit, sensor, metering pump. Wherein the monitoring system includes a closed-loop control loop of the chlorine dioxide generator composed of PLC, HMI, drive unit, sensor, and metering pump. Described cloud platform refers to the application server, Web server and database system deployed in Internet cloud, collects the data of chlorine dioxide generating device in PLC through Internet, 3G / 4G wireless network, PPI-3G / 4G wireless network gateway, and to PLC Send commands to control the chlorine dioxide generator.

[0018] The PPI-3G / 4G wireless network gateway includes a 3G / 4G wireless module and an RS485 serial module, which are used to estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com