Heat transfer enhanced chemical heat storage device and heat storage system applying same

A chemical heat storage and enhanced technology, applied in the field of heat storage system, can solve the problems of poor heat transfer performance and low thermal efficiency, and achieve the effect of high thermal efficiency and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

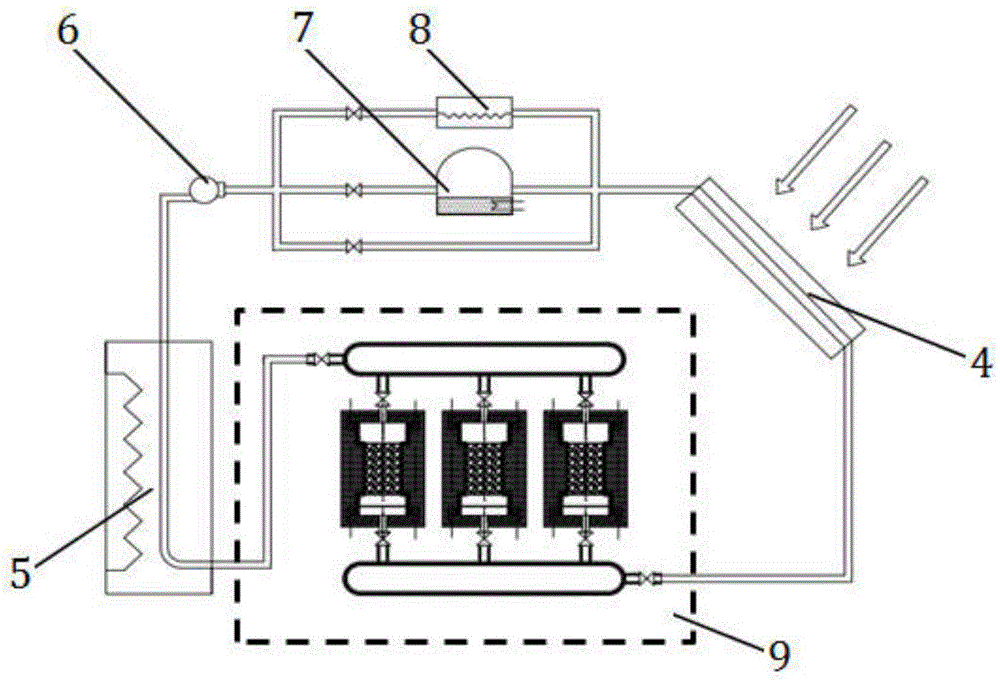

[0026] Such as figure 1 As shown, this embodiment relates to a heat transfer enhanced chemical heat storage device 9, comprising: a heat storage unit 2 and a first gas buffer tank 1 connected to the gas inlet port 21 and the gas outlet port 26 of the heat storage unit 2 respectively , the second gas buffer tank 3;

[0027] Such as figure 2 As shown, the heat storage unit 2 includes: an air distribution plate 22, a stainless steel wire mesh 23, a heat storage medium 24 and a bracket 25, wherein: the heat storage medium 24 is wrapped and fixed by a stainless steel wire mesh 23, and the stainless steel wire mesh 23 passes through the bracket 25 is fixed inside the heat storage unit 2 , and an air distribution plate 22 is arranged between the gas inlet port 21 and the heat storage medium 24 .

[0028] The heat storage medium 24 is preferably Mg(OH) 2 , chemically pure Mg(OH) with a purity of 95% produced by Aladdin Chemical Reagent Co., Ltd. 2 .

[0029] The air distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com