Plate-fin heat exchanger capable of being used for floating platform

A technology of plate-fin heat exchanger and floating platform, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. Affect the heat exchange effect of the device and other problems, to achieve the effect of enhancing the anti-shake performance, increasing the medium processing capacity, and saving the amount of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

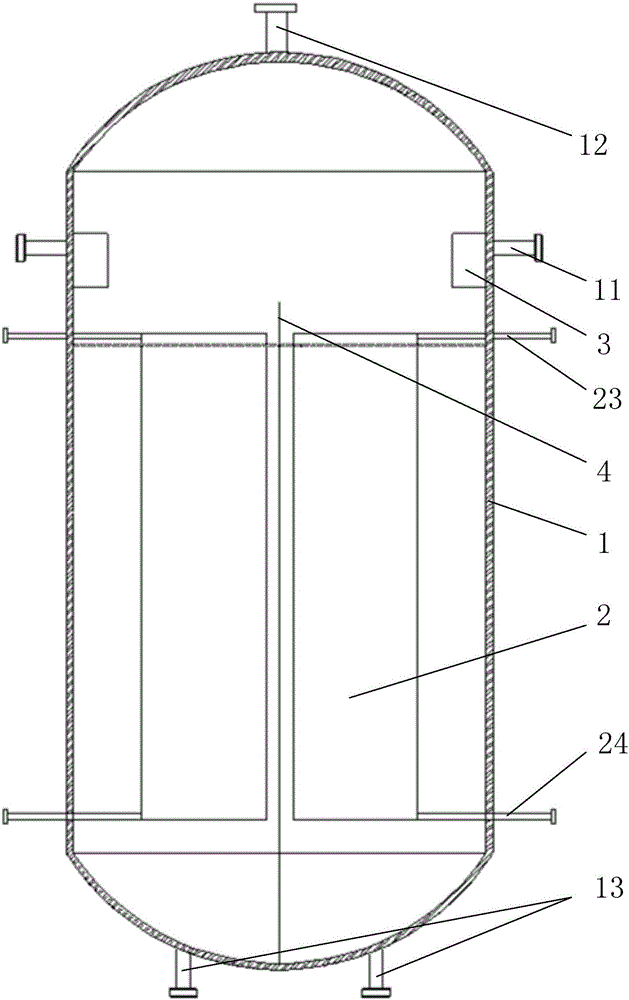

[0023] Such as figure 1 , figure 2 and image 3 As shown, a plate-fin heat exchanger applicable to a floating platform according to the present invention includes a shell 1 , at least one core 2 and at least one refrigerant distributor 3 . Wherein, at least one refrigerant inlet 11 is arranged on the upper part of the side wall of the shell 1, a gas phase refrigerant outlet 12 is arranged on the top, and at least one liquid phase refrigerant outlet 13 is arranged on the bottom, and the refrigerant inlet 11 and the liquid phase refrigerant outlet The number of 13 is the same as the number of cores 2 .

[0024] Such as Figure 4 ~ Figure 8 As shown, the core body 2 is arranged in the housing 1 and is located below the refrigerant inlet 11, and each core body 2 corresponds to each refrigerant inlet 11 and liquid-phase refrigerant outlet 13 one by on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com