Oxygen-enriched combustion device of circulating fluidized bed and air supply method for oxygen-enriched combustion thereof

A circulating fluidized bed and oxygen-enriched combustion technology, which is applied in the field of circulating fluidized bed, can solve problems such as ignition and combustion, safety issues, and reduce the reasonable distribution of the boiler thermal system, so as to improve combustion efficiency, reduce combustion costs, and increase economy. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

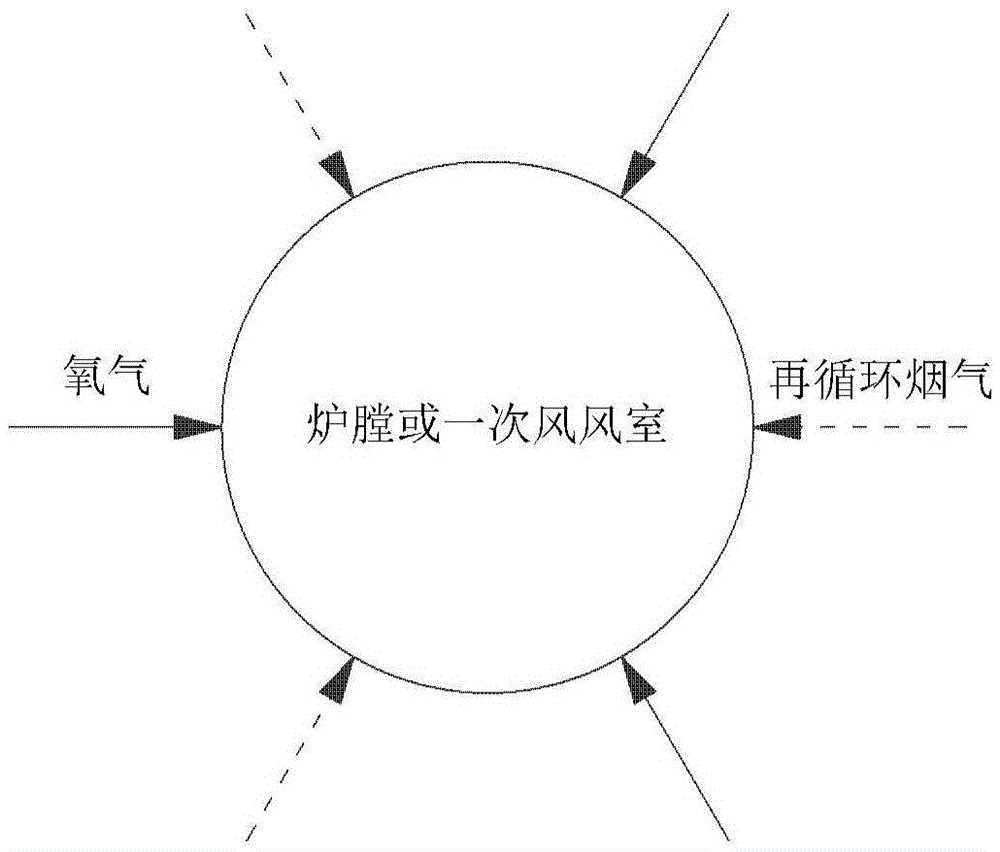

[0047] figure 1 It shows a schematic diagram of the air supply system for high oxygen concentration circulating fluidized bed oxygen-enriched combustion in Example 1 of the present invention. The boiler body 1 produces flue gas carrying dust into the flue gas pipeline, and the CO in the flue gas 2 The concentration can reach more than 90%. After passing through the flue gas heat exchanger 5 and the bag filter 6 in turn, the flue gas after dust removal is divided into two parts, and one part enters the CO 2 The purification and compression system 7 is used for the purification and compression system, and after dehydration, purification and compression, it becomes high-concentration CO 2 Liquid, which can be directly used or stored to achieve CO 2 The purpose of capture and storage; the other part enters the recirculation flue gas pipeline, and first passes through the condenser 8 for dehydration treatment to obtain dry recirculation flue gas with a water content of less than ...

Embodiment 2

[0049] figure 2 It shows a schematic diagram of the air supply system for high oxygen concentration circulating fluidized bed oxygen-enriched combustion in Example 2 of the present invention. The boiler body 1 produces flue gas carrying dust into the flue gas pipeline, and the CO in the flue gas 2 The concentration can reach more than 90%. After passing through the flue gas heat exchanger 5 and the bag filter 6 in turn, the flue gas after dust removal is divided into two parts, and one part enters the CO 2 The purification and compression system 7 is used for the purification and compression system, and after dehydration, purification and compression, it becomes high-concentration CO 2 Liquid, which can be directly used or stored to achieve CO 2 The purpose of capture and storage; the other part enters the recirculation flue gas pipeline, and first passes through the condenser 8 for dehydration treatment to obtain dry recirculation flue gas with a water content of less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com