Steel-straw plate composite anti-seismic wall and manufacturing installing method thereof

A technology of straw board and anti-seismic wall, applied in the direction of wall, anti-vibration, building components, etc., can solve the problems of environmental pollution, burning of plant straw, etc., and achieve the effect of reducing noise and environmental pollution, reducing burning waste, and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

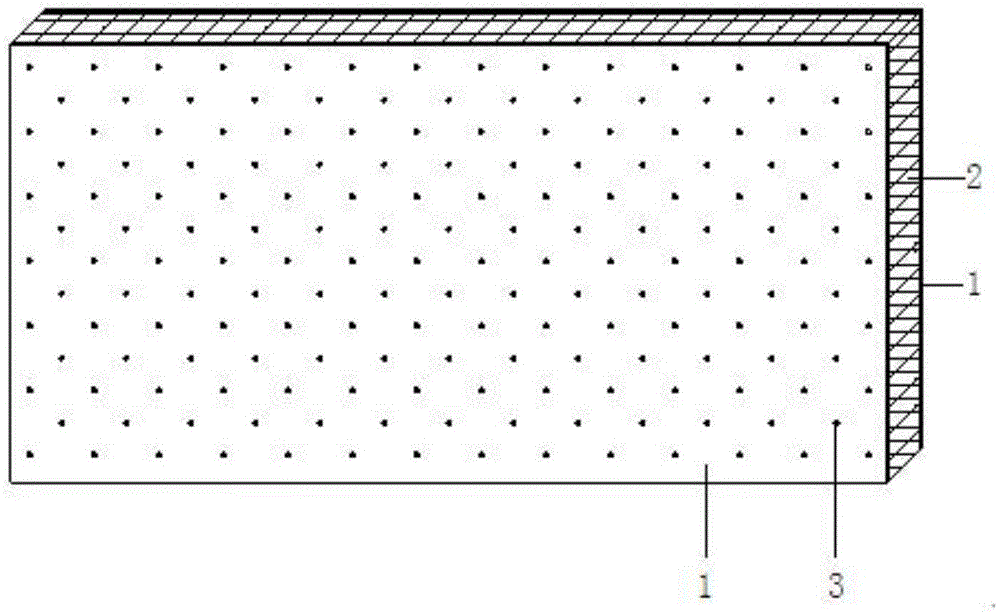

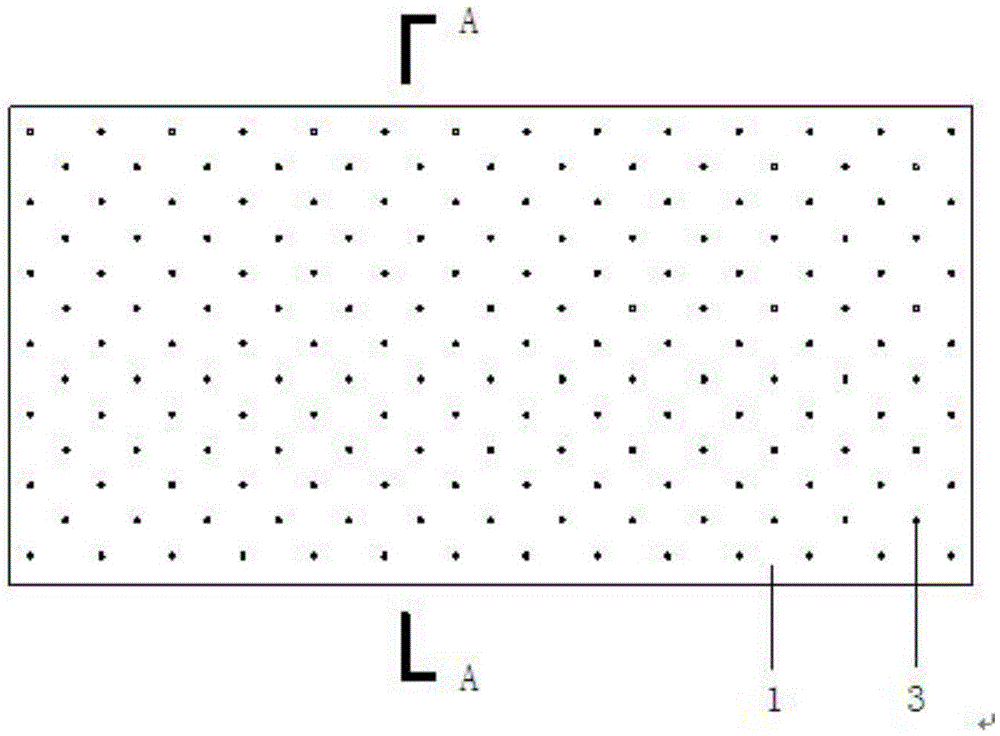

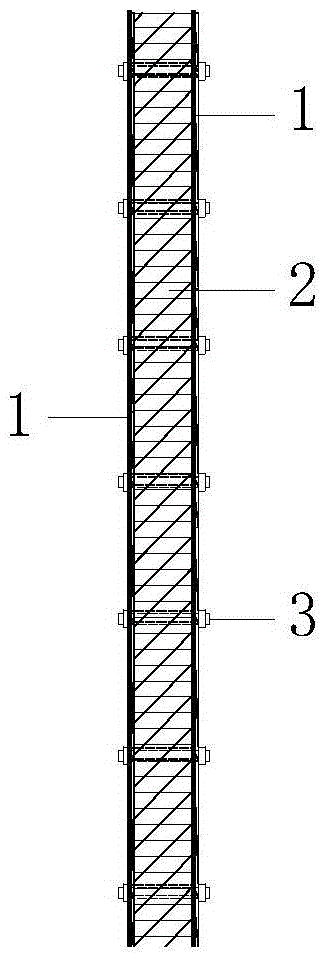

[0029] A steel-straw plate combined seismic wall of the present invention comprises two steel plates 1, one straw plate 2 and several high-strength bolts 3; the two steel plates 1 are respectively located on both sides of the straw plate 2; the steel plate 1 and the straw plate 2 They are connected by high-strength bolts 3; the steel plates 1, straw plates 2 and high-strength bolts 3 are produced in a mechanized assembly line in the factory, and the combined anti-seismic wall is assembled at the construction site. Steel plates, straw plates and high-strength bolts have good characteristics of disassembly and reassembly, in line with the concept of low-carbon, environmental protection and sustainable development.

[0030] In one embodiment of the present invention, the thickness of the steel plate is 5-25mm.

[0031] In one embodiment of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap