Anti-buckling steel plate shear wall with end columns and its construction method

A steel plate shear wall, anti-buckling technology, applied in the direction of walls, earthquake resistance, building components, etc., can solve the problems of insufficient energy consumption and bearing capacity, unfavorable opening of doors, windows, aisles, etc., to ensure the role, improve bearing performance and The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

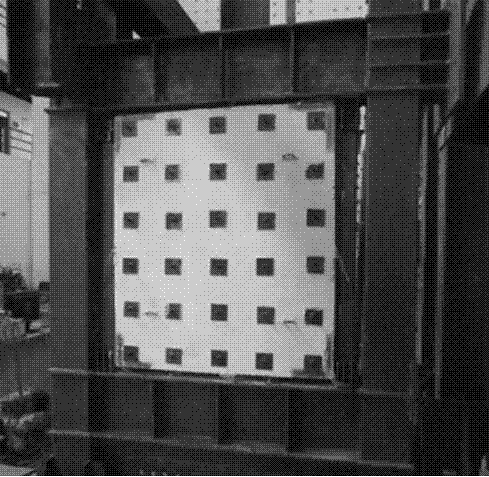

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

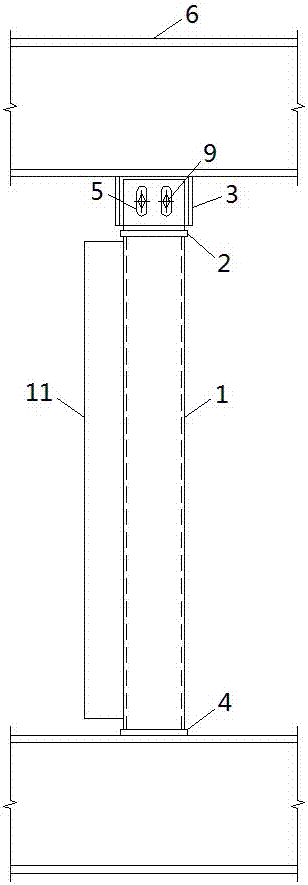

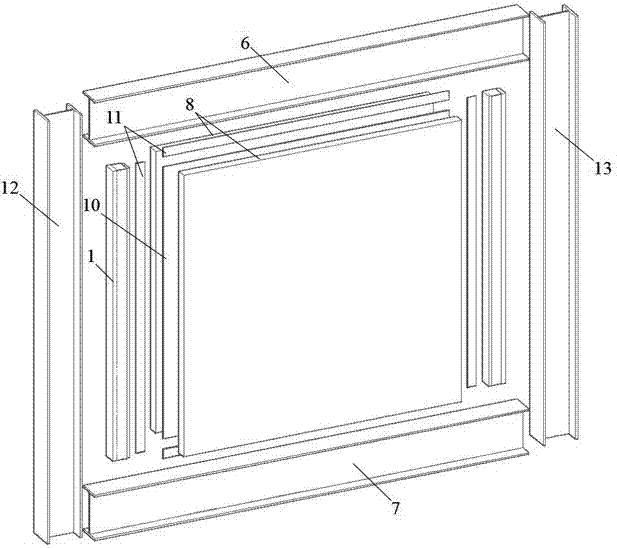

[0030] Such as Figure 1~4 As shown, a buckling-resistant steel plate shear wall with end columns includes a steel structure frame composed of left and right columns 12, 13 and upper and lower beams 6, 7, and the upper and lower beams are arranged in the steel structure frame. The anti-buckling steel plate wall connected by the lower beams 6 and 7, the buckling-resistant steel plate wall is composed of an embedded steel plate 10 in the middle and reinforced concrete cover plates 8 on both sides, and the upper and lower sides of the embedded steel plate 10 respectively pass through the upper and lower The fish plate 11 is connected with the upper and lower beams 6, 7, the two sides of the embedded steel plate 10 are respectively connected with the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com