A vertical compression test device suitable for bending large wall panels

A compression test and siding technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large ultimate compression load, difficult mechanical strength assessment, high price, etc., to reduce the impact of friction, convenient Precise vertical loading, the effect of preventing buckling failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

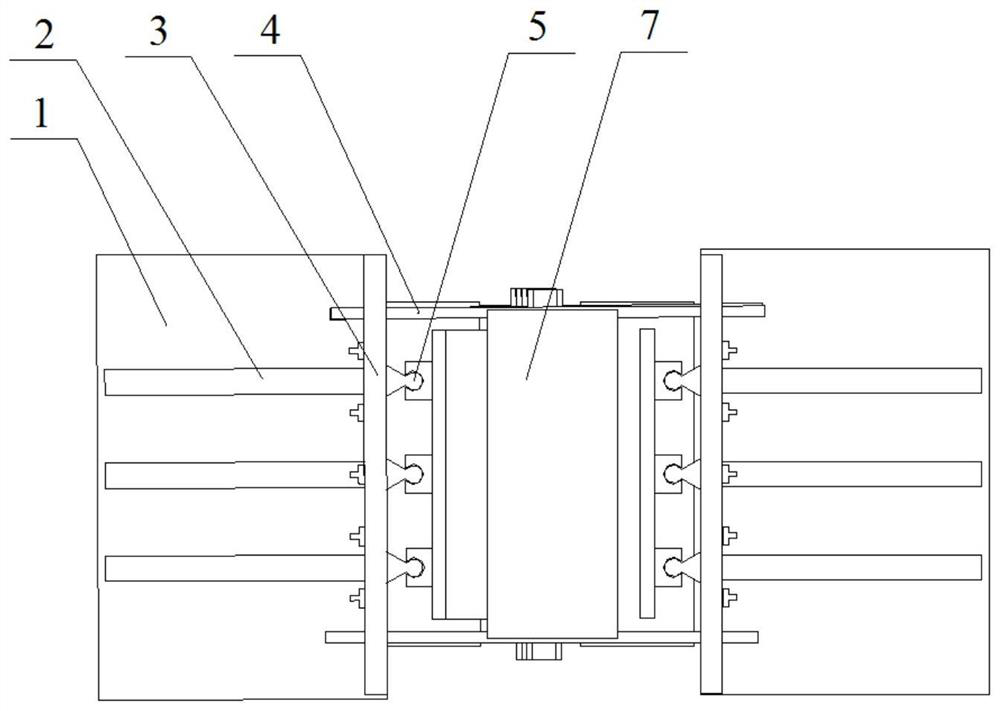

[0023] Such as Figure 1~4 As shown, the present invention is a test device suitable for bending large wall board compression, including base 1, reinforcing rib 2, fixed baffle 3, detachable protective baffle 4, slide rail 5, anti-buckling simply supported knife edge 6, loading Chuck 7, simply supported knife edge 8 at the loading end, test piece wall plate 9, sliding bearing 10, simply supported knife edge 11 at the fixed support end, inclined pad 12-, test piece 13. The left-right symmetrical fixed baffle 3 is welded on the base 1, and the base 1 and the fixed baffle 3 are reinforced wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com