A buckling-resistant energy-dissipating tube and its manufacturing process

A technology of anti-buckling energy consumption and manufacturing process, applied in the direction of earthquake resistance, bridge parts, building components, etc., can solve the problems of ductility, fatigue resistance, impact resistance, stability and durability, bearing capacity and poor energy dissipation performance, etc. To achieve the effect of reducing the amount of materials, improving the utilization rate, and improving the compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

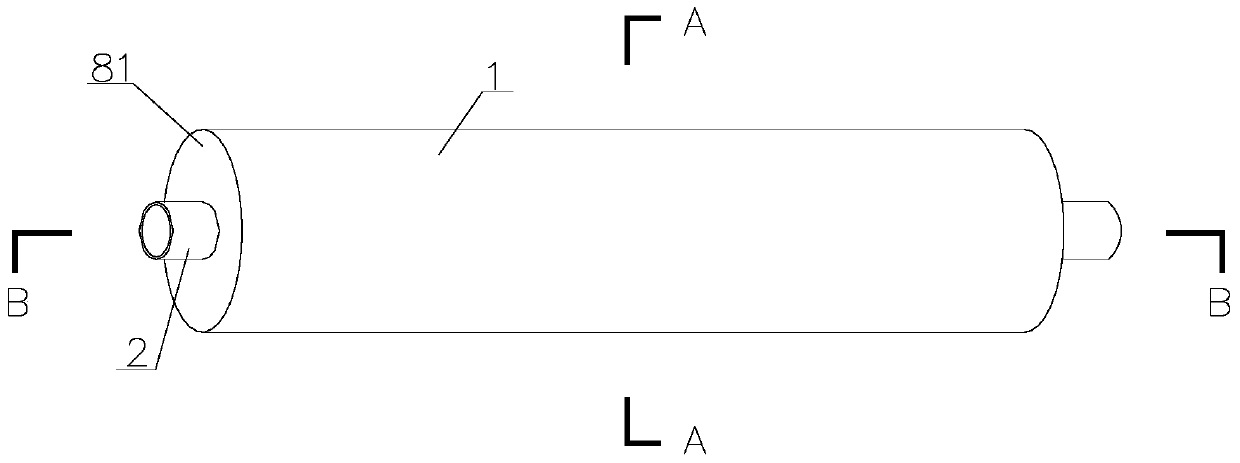

[0034] refer to Figure 1 to Figure 5 , an anti-buckling energy-dissipating tube, comprising a constraining outer tube 1, a core energy-dissipating inner tube 2 and a cover plate, wherein the core energy-dissipating inner tube 2 has a coaxial gap arranged in the constraining outer tube 1;

[0035] There are at least two rows of energy-dissipating devices on the ring of the core energy-dissipating inner tube 2, and there are at least two energy-dissipating holes 6 in each row of energy-dissipating devices; Longitudinal stiffeners are provided, and transverse stiffeners are arranged between adjacent longitudinal stiffeners;

[0036] Both ends of the constraint outer tube 1 are respectively fixedly connected to the cover plate, and both ends of the core energy-dissipating inner tube 2 protrude from the cover plate and are sealed and connected.

[0037] Further, at least two energy dissipation holes are arranged at equal intervals.

[0038] Still further, at least two transverse...

Embodiment 2

[0053] refer to Figure 1 to Figure 5 , a manufacturing process of an anti-buckling energy-dissipating tube, the manufacturing process comprising the following steps:

[0054] Step 1: Derust and degrease the outer surfaces of the constraining outer tube 1, core energy-dissipating inner tube 2, longitudinal stiffeners and transverse stiffeners, left and right cover plates, and constrain the outer tube and core energy-dissipating The cross-sections at both ends of the inner tube are polished to make the cross-section smooth and flat;

[0055] Step 2: Install energy-dissipating devices on the 2 rings of the core energy-dissipating inner pipe by means of a gas cutting process. There are at least two energy-dissipating holes 6 in each row of energy-dissipating devices;

[0056] The third step: grinding and rounding the edges and corners in the energy-dissipating hole 6 to reduce the influence of stress concentration;

[0057] Step 4: Install longitudinal stiffeners on the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com