Shredding device used for recycling polyester short fiber

A technology of recycled polyester and shredding, which is used in the production of complete sets of equipment for man-made threads, textiles and papermaking. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

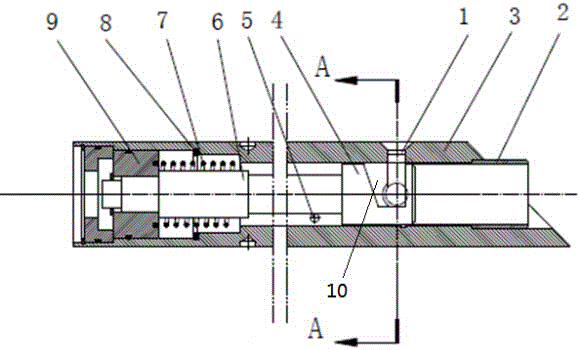

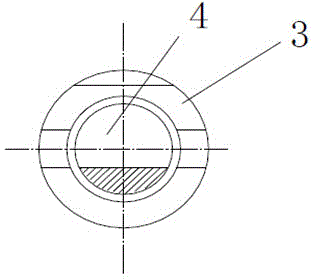

[0022] Such as figure 1 As shown, the shredding device for recycled polyester staple fiber includes a knife seat 3, two circular cutters arranged at the right end inside the knife seat, and a piston rod 6 and a piston 9 arranged at the left end inside the knife seat, and the left end of the piston rod is inserted into the The piston is locked with a nut, and the circular cutter is made of alloy steel through special heat treatment process.

[0023] Wherein a circular cutting knife 2 is a hollow cylinder, and is fixed on the knife seat 3 inside, and its left end is cutting edge. Another circular cutter 4 is a solid cylinder, and its left end is fixed on the piston rod 6 right-hand ends, and its right-hand end stretches into its inside from the hollow cylindrical circular slice 2 left end, and the inner of the hollow cylindrical circular cutter 2 The surface is also a guide bush for the solid cylindrical circular cutter 4 simultaneously.

[0024] The middle of the solid cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com