Oxygen-bearing steel belt and production method thereof

A production method and steel strip technology, applied in the field of metallurgy, can solve the problems affecting the normal use of materials, low steel-aluminum composite performance, high oxygen content, etc., and achieve the effects of low production process cost, high production stability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

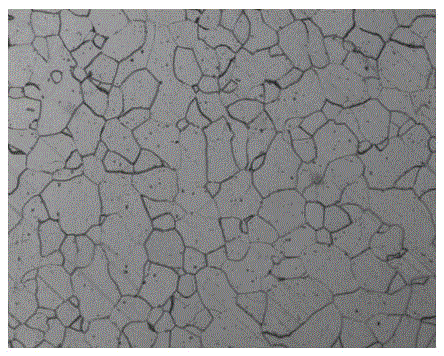

Embodiment 1

[0028] An oxygen-containing steel strip, the mass fraction of chemical composition is: C: 0.007%, Mn: 0.22%, Si: 0.003%, S: 0.005%, P: 0.018%, Al: 0.002%, N: 0.0024%, [ O]: 0.0030%, the balance being iron and inevitable impurities.

[0029] Oxygen-containing steel strip production method, the specific steps are as follows:

[0030] Hot metal desulfurization: the molten iron is desulfurized, and the weight percentage of S is controlled to be 0.006%; converter smelting: the weight percentage of P is controlled to be 0.020%; refining outside the furnace; 0.002%, [O] 0.0050%; continuous casting: continuous casting uses a covering agent with a weight percentage of C of 0.1%, and uses argon gas for protective casting, and the argon gas flow rate is 10Nm 3 / h; continuous casting slab heating: heating temperature 1230°C; hot rolling: hot rolling process, control finish rolling temperature 870°C; coiling: control coiling temperature 640°C.

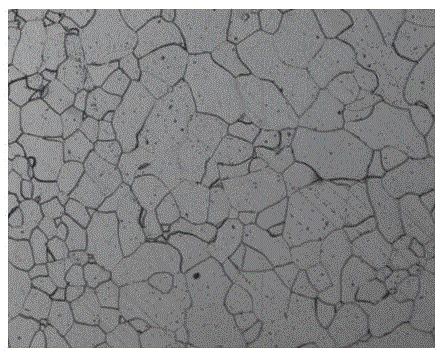

Embodiment 2

[0032] An oxygen-containing steel strip, the mass fraction of chemical composition is: C: 0.007%, Mn: 0.22%, Si: 0.003%, S: 0.005%, P: 0.016%, Al: 0.002%, N: 0.0022%, [ O]: 0.0028%, the balance being iron and inevitable impurities.

[0033] Oxygen-containing steel strip production method, the specific steps are as follows:

[0034] Hot metal desulfurization: the molten iron is desulfurized, and the weight percentage of S is controlled to be 0.005%; converter smelting: the weight percentage of P is controlled to be 0.018%; refining outside the furnace; 0.002%, [O] 0.0040%; continuous casting: continuous casting uses a covering agent with a weight percentage of C of 0.1%, and uses argon gas for protection casting, and the argon gas flow rate is 12Nm 3 / h; continuous casting slab heating: heating temperature 1255°C; hot rolling: hot rolling process, control finish rolling temperature 890°C; coiling: control coiling temperature 660°C.

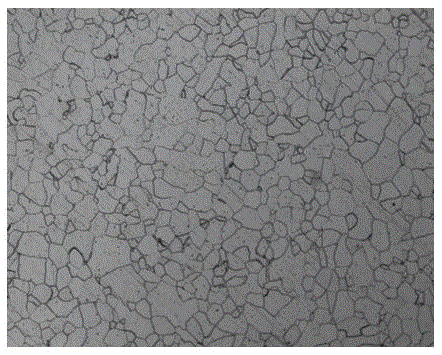

Embodiment 3

[0036] An oxygen-containing steel strip, the mass fraction of chemical composition is: C: 0.008%, Mn: 0.15%, Si: 0.004%, S: 0.006%, P: 0.020%, Al: 0.003%, N: 0.0040%, [ O]: 0.0050%, the balance being iron and inevitable impurities.

[0037] Oxygen-containing steel strip production method, the specific steps are as follows:

[0038] Hot metal desulfurization: the molten iron is desulfurized, and the weight percentage of S is controlled to be 0.006%; converter smelting: the weight percentage of P is controlled to be 0.020%; refining outside the furnace; 0.003%, [O] 0.0050%; continuous casting: continuous casting uses a covering agent with a weight percentage of C of 0.1%, and uses argon gas for protective casting, and the argon gas flow rate is 11Nm 3 / h; continuous casting slab heating: heating temperature 1240°C; hot rolling: hot rolling process, control finish rolling temperature 885°C; coiling: control coiling temperature 655°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com