Metal heat compound addition fluxing agent and preparing method thereof

A technology of composite addition and metal heat, applied in the field of alloy flux, can solve the problems of easy oxidation, poor use effect, poor refining effect, etc., and achieve good fluidity and tight composite surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

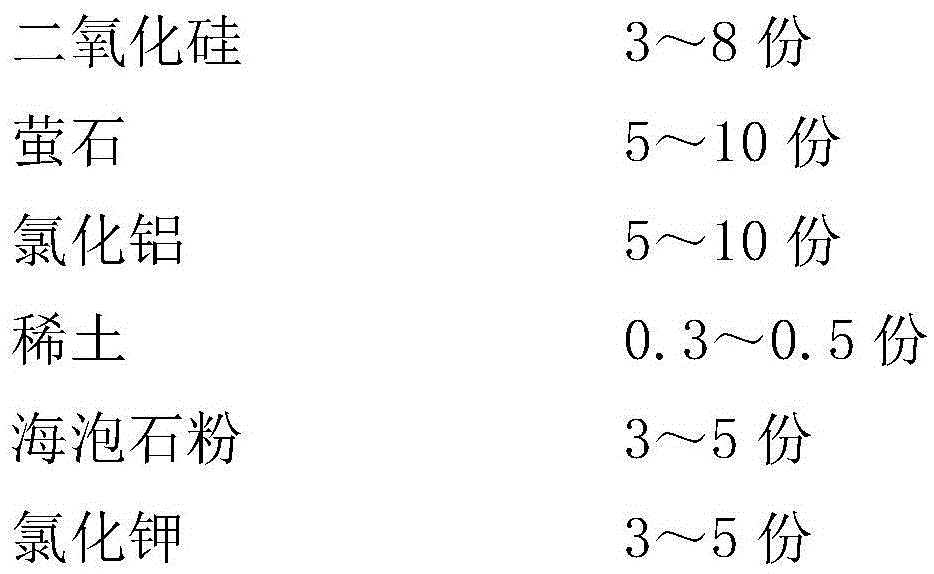

[0015] A kind of metal thermal composite additive flux, made of the following components by weight,

[0016]

[0017]

[0018] A preparation method for metal thermal composite adding flux, comprising the following steps: performing grinding treatment on silicon dioxide, fluorite, aluminum chloride, rare earth, sepiolite powder, potassium chloride, magnesium oxide and calcium fluoride respectively, and then The ground powder is sieved, the size of the sieve is 100-200 mesh, and then the sieved powder is fully mixed under the temperature condition of 70-100°C.

Embodiment 2

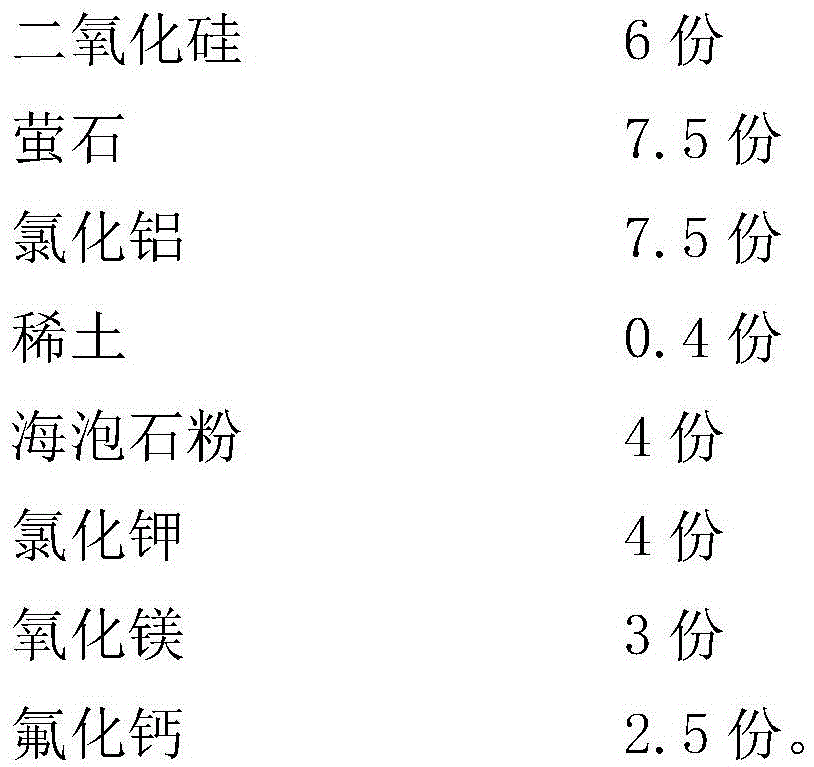

[0020] A metal thermal composite additive flux, characterized in that it is made of the following components in parts by weight,

[0021]

[0022] A preparation method for metal thermal composite adding flux, comprising the following steps: performing grinding treatment on silicon dioxide, fluorite, aluminum chloride, rare earth, sepiolite powder, potassium chloride, magnesium oxide and calcium fluoride respectively, and then The ground powder is sieved, the size of the sieve is 100-200 mesh, and then the sieved powder is fully mixed at a temperature of 70-100°C.

Embodiment 3

[0024] A kind of metal thermal composite additive flux, made of the following components by weight,

[0025]

[0026]

[0027] A preparation method for metal thermal composite adding flux, comprising the following steps: performing grinding treatment on silicon dioxide, fluorite, aluminum chloride, rare earth, sepiolite powder, potassium chloride, magnesium oxide and calcium fluoride respectively, and then The ground powder is sieved, the size of the sieve is 100-200 mesh, and then the sieved powder is fully mixed at a temperature of 70-100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com