Sintering method of high-chromium type vanadium titano-magnetite

A technology of vanadium titanomagnetite and sintering method is applied in the sintering of ore and the sintering field of high chromium vanadium titanomagnetite, which can solve the problem of low strength of high chromium vanadium titanomagnetite sintering and high chromium vanadium sintering. Difficulty sintering titanomagnetite and other problems, to achieve the effect of increasing the amount of liquid phase, increasing the strength, and increasing the silicate binder phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

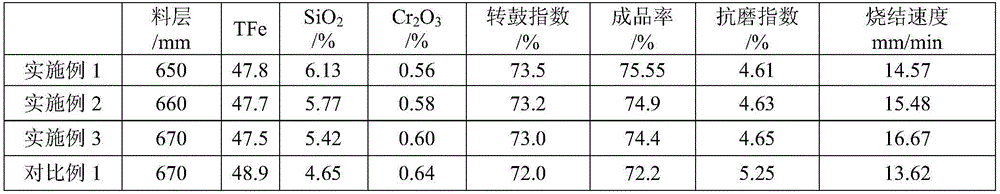

[0014] The high chromium vanadium titanomagnetite sintering method of the present invention will be described in detail below in conjunction with examples.

[0015] For high-chromium vanadium-titanium magnetite, due to the low content of TFe, TiO 2 High content, Cr 2 o 3 High content, SiO 2 If the content is low, the liquid phase will be low during the sintering process, which will result in low strength of sintered ore and more powder, which will seriously affect the output and quality of sintered ore.

[0016] As an embodiment of the present invention, the sintering method of concrete high-chromium type vanadium-titanium magnetite comprises the following steps:

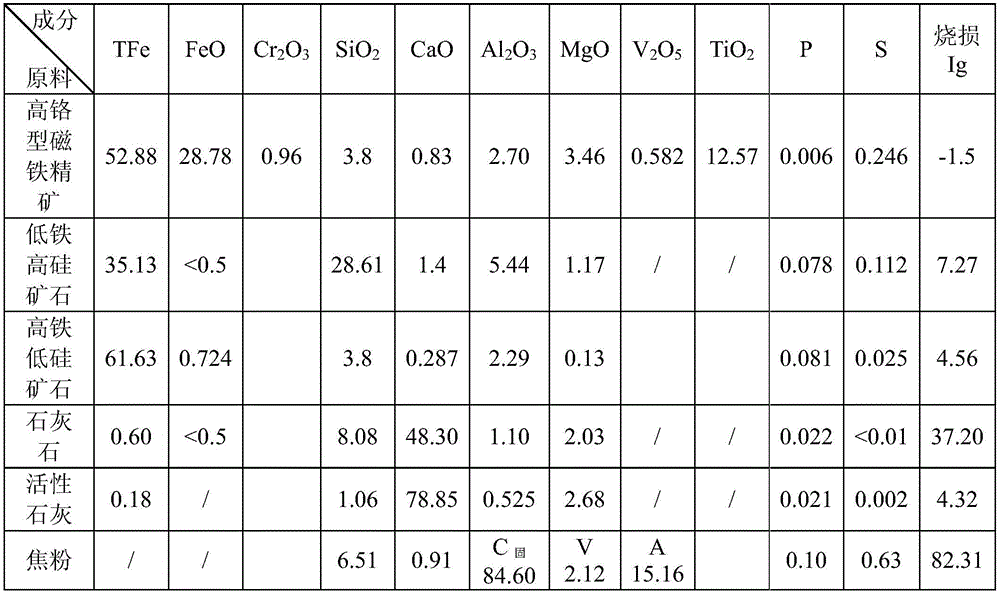

[0017] Step 1, 3-8 parts by weight of low-iron high-silicon powder ore, 18-22 parts of high-iron and low-silicon ore powder, 50-60 parts of high-chromium vanadium-titanium magnetite, 3-8 parts of limestone Powder, 6-10 parts of active lime and 4.5-5 parts of coke powder are mixed to form a mixture, and the alkal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com