All cationic drilling fluid

An all-cation and cation technology, which is applied in the field of all-cation drilling fluid, can solve the problems of anion and cation incompatibility, achieve the effect of increasing drilling speed and avoiding dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

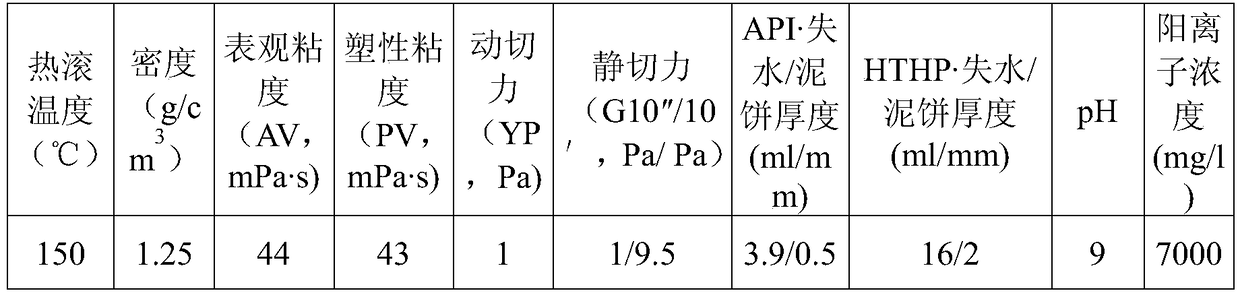

[0024] Indoor evaluation of all cationic drilling fluid performance:

[0025] In the all-cation drilling fluid provided in this embodiment, each cubic meter of drilling fluid comprises: 50kg bentonite, 20kg cationic lignite first cationic fluid loss reducer (CPF), 10kg cationic lignin second cationic fluid loss reducer (CPF- 1), 8kg of the first cationic coating agent (CPH-1), 6kg of polyacrylamide second cationic coating agent (CPH-2) with a molecular weight of about 4 million, 10kg of quaternary ammonium polymers with a molecular weight of less than 500 as cationic suppression (CPI), 20kg of cationic asphalt with a particle size of 120-150 mesh as a cationic plugging agent, and the rest as water. Then add limestone powder to it until the drilling fluid density is 1.25kg / cm 3 , add 3kgNaOH to adjust the pH value to 9. The all-cation drilling fluid was aged at 150°C for 24 hours, and the test performance is shown in Table 1.

[0026] Table 1

[0027]

[0028] (where API...

Embodiment 2

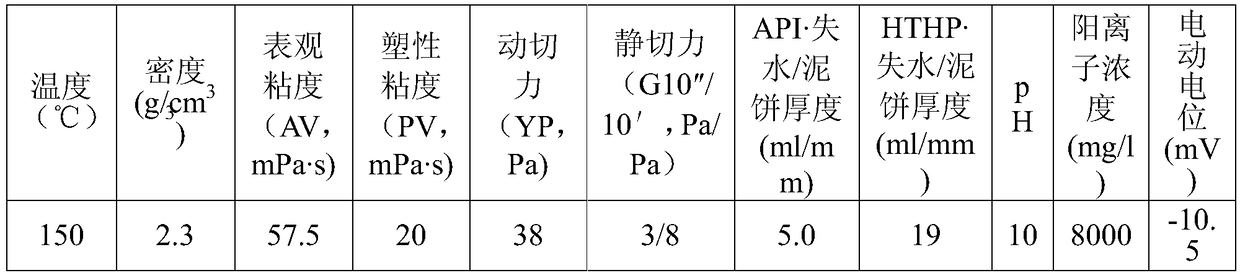

[0031] Indoor evaluation of anti-saturated salt and anti-calcium performance of all-cation drilling fluid:

[0032] In the full cationic drilling fluid provided in this embodiment, every cubic meter of drilling fluid includes: 30kg bentonite, 10kg cationic inhibitor (CPI), 8kg first cationic coating agent (CPH-2), 6kg second cationic coating agent (CPH-2), 20kg of the first cationic fluid loss control agent (CPF), 20kg of the second cationic fluid loss control agent (CPF), 20kg of cationic blocking agent (CPA), and the rest is water. Wherein the selection of each cationic preparation can be the same as in Example 1. Add more spars to it until the drilling fluid density is 2.3kg / cm 3 , adjust the pH value to 10.

[0033]During the test, 360kg of sodium chloride and 60kg of gypsum were added to the above-mentioned all-cation drilling fluid, and the all-cation drilling fluid was aged at 150°C for 24 hours. The test performance is shown in Table 2.

[0034] Table 2

[0035] ...

Embodiment 3

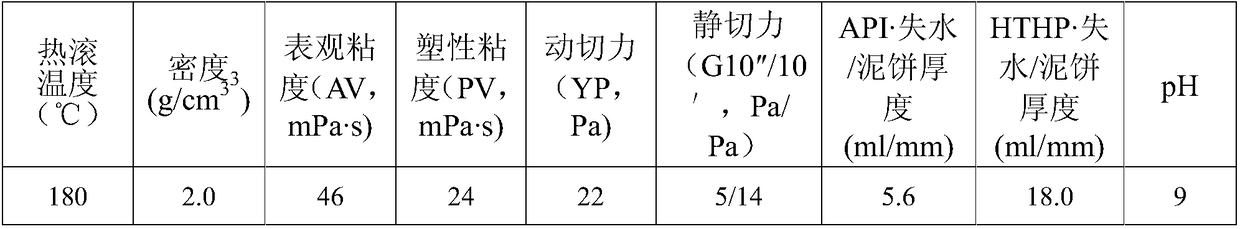

[0038] Indoor evaluation of the temperature resistance performance of all-cation drilling fluid:

[0039] In the full cationic drilling fluid provided in this embodiment, every cubic meter of drilling fluid includes: 30kg bentonite, 10kg cationic inhibitor (CPI), 8kg first cationic coating agent (CPH-2), 6kg second cationic coating agent (CPH-2), 20kg of the first cationic fluid loss control agent (CPF), 20kg of the second cationic fluid loss control agent (CPF), 20kg of cationic blocking agent (CPA), and the rest is water. Wherein the selection of each cationic preparation can be the same as in Example 1. Add more spars to it until the drilling fluid density is 2.3kg / cm 3 , adjust the pH value to 10,

[0040] During the test, 300kg of sodium chloride was added to the above-mentioned all-cation drilling fluid, and the drilling fluid was aged at 180°C for 24 hours. The test performance is shown in Table 3.

[0041] table 3

[0042]

[0043] From the various data in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com