A low-temperature oil well early-strength cementing agent

An oil well, low temperature technology, applied in the field of oilfield chemicals, to achieve the effect of reducing surface tension, small shrinkage, and promoting the speed of cement hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

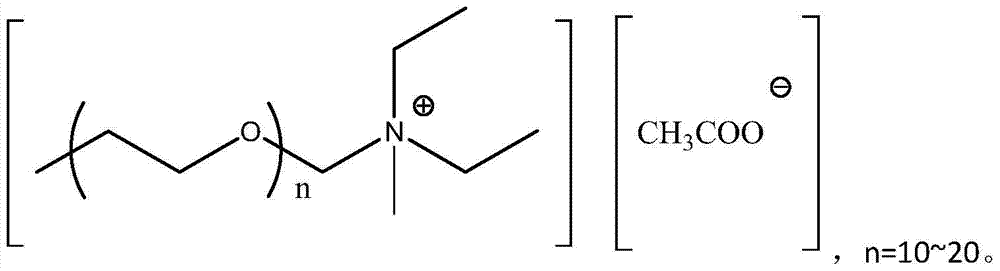

[0029] 85 parts of ionic liquid, 15 parts of polycarboxylate superplasticizer, wherein, the structural formula of ionic liquid is:

[0030]

[0031] Use PO52.5 medium sulfate-resistant Portland cement, control the water-cement ratio of the cement slurry to 0.37, and the dosage is 0.8%. The test is carried out according to the above-mentioned experimental process, and the results are shown in the following table:

[0032] Performance Testing

[0033]

Embodiment 2

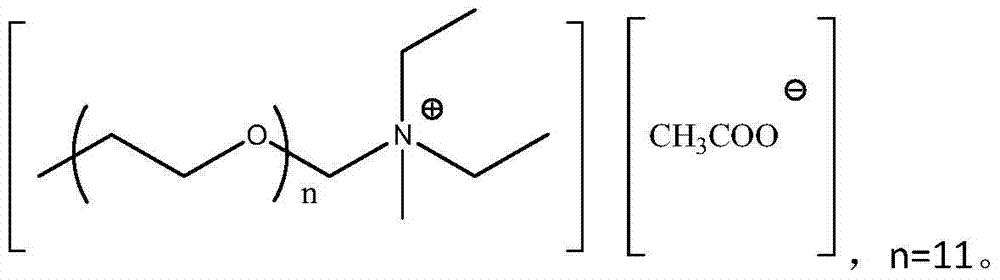

[0035] 90 parts of ionic liquid, 10 parts of polycarboxylate superplasticizer, wherein, the structural formula of ionic liquid is:

[0036]

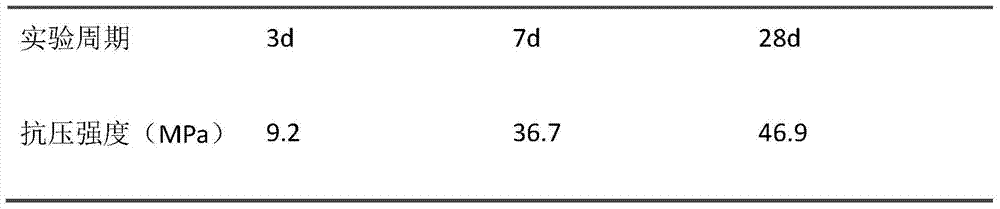

[0037] Use PO52.5 medium sulfate-resistant Portland cement, control the water-cement ratio of the cement slurry to 0.37, and the dosage is 1.0%. The test is carried out according to the above-mentioned experimental process, and the results are shown in the following table:

[0038] Performance Testing

[0039]

Embodiment 3

[0041] 95 parts of ionic liquid, 5 parts of polycarboxylate superplasticizer, wherein, the structural formula of ionic liquid is:

[0042]

[0043] Use PO52.5 medium sulfate-resistant Portland cement, control the water-cement ratio of the cement slurry to 0.36, and the dosage is 0.9%. The test is carried out according to the above-mentioned experimental process, and the results are shown in the following table:

[0044] Performance Testing

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com