A kind of preparation method of high dispersion, high solid content slurry titanium dioxide

A technology with high solid content and high dispersion, applied in chemical instruments and methods, dyeing polymer organic compound treatment, fibrous fillers, etc., can solve the problems of weather resistance and storage stability, low solid content of titanium dioxide, high production cost, etc. problems, achieve the effect of improving dispersion, increasing solid content, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the slurry titanium dioxide with high dispersion and high solid content provided by the present invention includes the step of further performing wet coating treatment on the titanium dioxide slurry after inorganic surface treatment by using a water reducer.

[0025] According to the characteristics of titanium dioxide products, the present invention combines the water reducer with titanium dioxide by adopting a special treatment method. The water reducer is usually an anionic surfactant, and the polar hydrophilic group of the water reducer is directional adsorbed. On the particle surface, it associates with water molecules in the form of hydrogen bonds, and the hydrogen bond association between water molecules forms a stable water film on the particle surface, preventing direct contact between particles and increasing the inter-particle Excellent sliding ability, plays a lubricating role, improves the fluidity of the slurry, and can further imp...

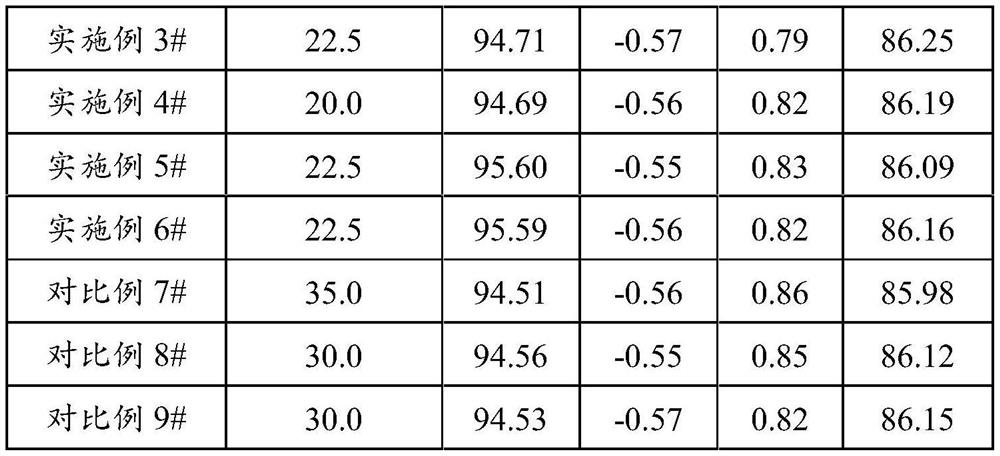

Embodiment 1

[0036] Take the qualified slurry and dilute it to 300g / L, raise the temperature to 80°C, adjust the pH to 10.5 with sodium hydroxide solution, apply silicon-aluminum inorganic coating to it by conventional methods, then raise the temperature to 95°C, and add 5 ‰ water reducer Prad 1241 (polycarboxylate water reducer, water reducing rate ≥ 25) (the amount of water reducer added is calculated by the weight of dry titanium dioxide in the slurry), homogenized for 30 minutes, washed with water until the conductivity of the filter cake ≤ 80 μs / cm, and then add a small amount of water (just wet the filter cake) to the filter cake for beating and dispersion, and sand-mill the slurry through a 400-mesh sieve to obtain slurry titanium dioxide 1#.

Embodiment 2

[0038] Take the qualified slurry and dilute it to 300g / L, raise the temperature to 80°C, adjust the pH to 10.5 with sodium hydroxide solution, apply silicon-aluminum inorganic coating to it by conventional methods, raise the temperature to 95°C, and add 5‰ within 15 minutes Water reducing agent β-naphthalene sulfonate formaldehyde condensate (naphthalene-based high-efficiency water reducing agent, water reducing rate ≥ 20) (the amount of water reducing agent added is calculated by the weight of dry titanium dioxide in the slurry), homogenized for 30 minutes, washed with water until The conductivity of the filter cake is ≤80μs / cm, and then a small amount of water (just wet the filter cake) is added to the filter cake for beating and dispersion, and the slurry is sand-milled through a 400-mesh sieve to obtain the slurry titanium dioxide 2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com