Gel film with curdlan quaternary ammonium salt and polyvinyl alcohol and antibacterial application of gel film

A technology of polyvinyl alcohol gel and polyvinyl alcohol, which is applied in the direction of fungicides, chemicals for biological control, biocides, etc., can solve the problems of decreased elongation and solubility, and achieves pollution-free, stable Good performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

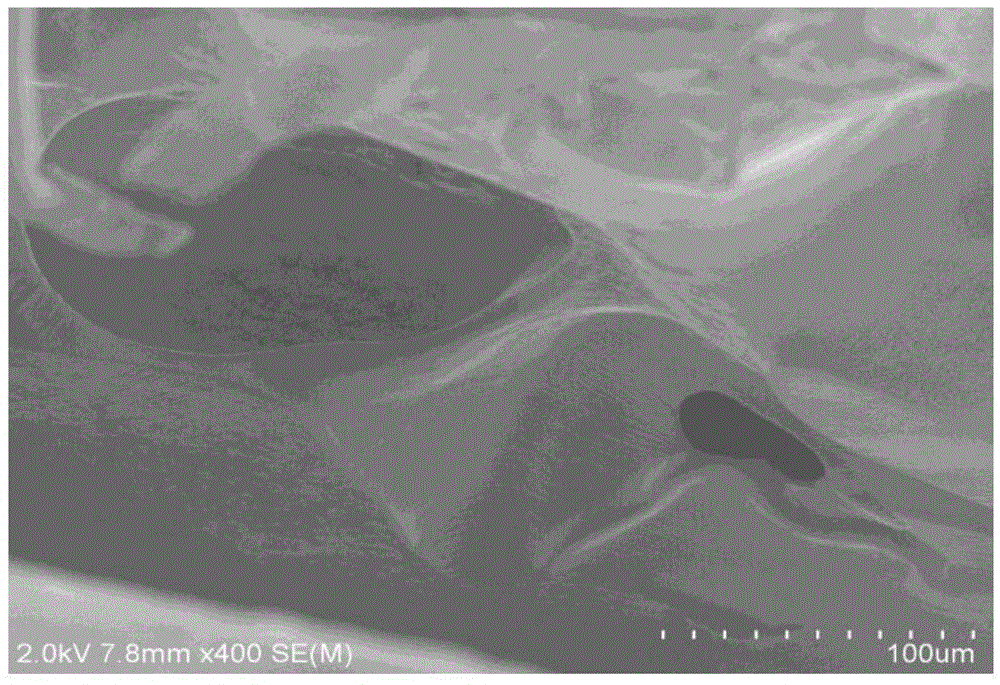

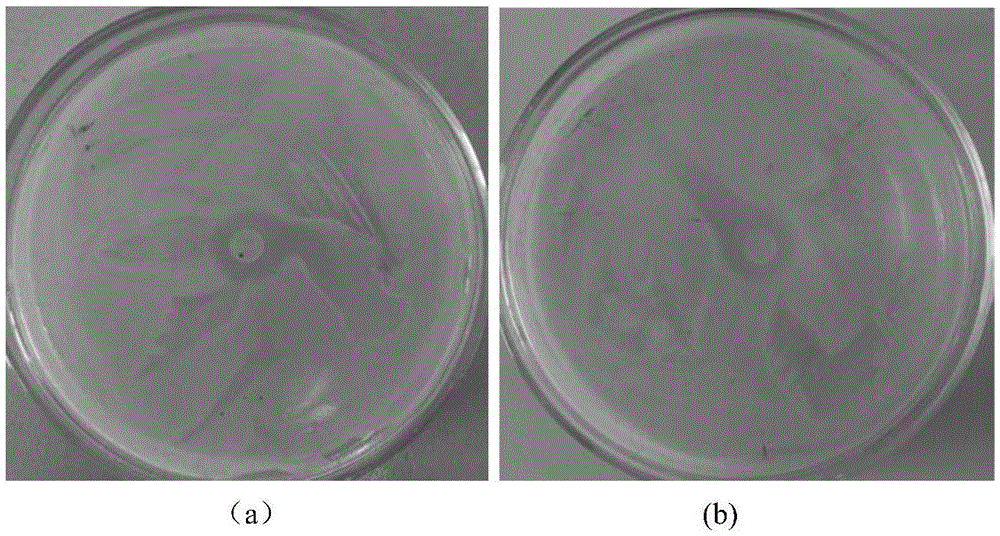

[0030] Example 1: (1) Take 4g of polyvinyl alcohol and soak it in 100mL of deionized water at room temperature for 30min, stir and dissolve for 2h to obtain a polyvinyl alcohol solution; (2) Take 0.12g of sucrose ester S-1570 and add it to (1), Stir and dissolve at 30°C for 1h; (3) Add 0.12g Span-80 to 0.6g liquid paraffin and stir at 30°C for 0.5h; (4) Drop the paraffin mixture prepared in (3) into (2) The prepared solution was stirred and emulsified at 30°C for 8h; (5) 1g of epoxy soybean oil was added to the emulsion prepared in (4), and stirred at 60°C for 0.5h; (6) 1g of epoxidized soybean oil Add ammonium salt to the emulsion prepared in (5), stir and dissolve for 2h; (7) Pour the mixed solution prepared in (6) into the container, flatten and degas, and place the container at -10℃ to freeze 4 Then, take out the container and thaw at room temperature for 3 hours. After repeating the above freezing and thawing process 3 times, it is placed in air drying at 30° C. to obtain ...

Embodiment 2

[0031] Example 2: (1) Take 2.5 g of polyvinyl alcohol and soak in 100 mL of deionized water at room temperature for 40 minutes, stir and dissolve for 2 hours to obtain a polyvinyl alcohol solution; (2) Take 0.16 g of sucrose ester S-1570 and add it to (1) , Stir and dissolve at 60℃ for 1h; (3) Add 0.16g Span-80 to 0.8g liquid paraffin and stir for 0.5h at 60℃; (4) Drop the paraffin mixture prepared in (3) into (2) The prepared solution was stirred and emulsified at 60°C for 5h; (5) 0.5g of glycerin was added to the emulsion prepared in (4), and stirred at 60°C for 0.5h; (6) 2.5g of Koderan gum quaternary ammonium salt Add the emulsion prepared in (5), stir to dissolve for 2h; (7) Pour the mixed solution prepared in (6) into a container, spread it out and degas, put the container at -20℃ and freeze for 4 hours, Then, the container was taken out and thawed at room temperature for 3 hours, and after the above freezing and thawing process was repeated 5 times, it was placed in air ...

Embodiment 3

[0032] Example 3: (1) Take 3.5 g of polyvinyl alcohol and soak it in 100 mL of deionized water at room temperature for 40 minutes, stir and dissolve for 2 hours to obtain a polyvinyl alcohol solution; (2) Take 0.20 g of sucrose ester S-1570 and add it to (1) , Stir and dissolve at 80℃ for 1h; (3) Add 0.20g Span-80 to 1.0g liquid paraffin and stir at 80℃ for 0.5h; (4) Drop the paraffin mixture prepared in (3) into (2) The prepared solution was stirred and emulsified at 80°C for 2h; (5) 1.5g of glycerin was added to the emulsion prepared in (4), and stirred at 80°C for 0.5h; (6) 1.5g of quaternary ammonium salt Add the emulsion prepared in (5), stir to dissolve for 2h; (7) Pour the mixed solution prepared in (6) into the container, spread it out and degas, put the container at -10°C and freeze for 4 hours, Then, the container was taken out and thawed at room temperature for 3 hours, and after the above freezing and thawing process was repeated 3 times, it was placed in air drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com