Ceramsite composite self-heat-insulation wall material and method for preparing same

A wall material, self-insulation technology, applied in the field of building energy saving, can solve the problems of poor waterproof effect, poor insulation of wall materials, poor waterproof and strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing a self-insulating wall material, comprising the following steps:

[0056] a) After mixing and beating the base material, the waterproof enhancer described in any one of the above technical solutions and water, the first prefabricated slurry is obtained;

[0057] Or after mixing one or both of the matrix material, polypropylene fiber and filler, the waterproof enhancer described in any one of the above technical solutions and water for beating, the second prefabricated slurry is obtained;

[0058] b) mixing the first prefabricated slurry or the second prefabricated slurry obtained in the above steps, ceramsite and foaming agent, and then pouring and molding to obtain a green body;

[0059] c) After natural curing of the body obtained in the above steps, a self-insulating wall material is obtained.

[0060] The selection range and optimization principles of the raw materials in the present invention are consisten...

Embodiment 1

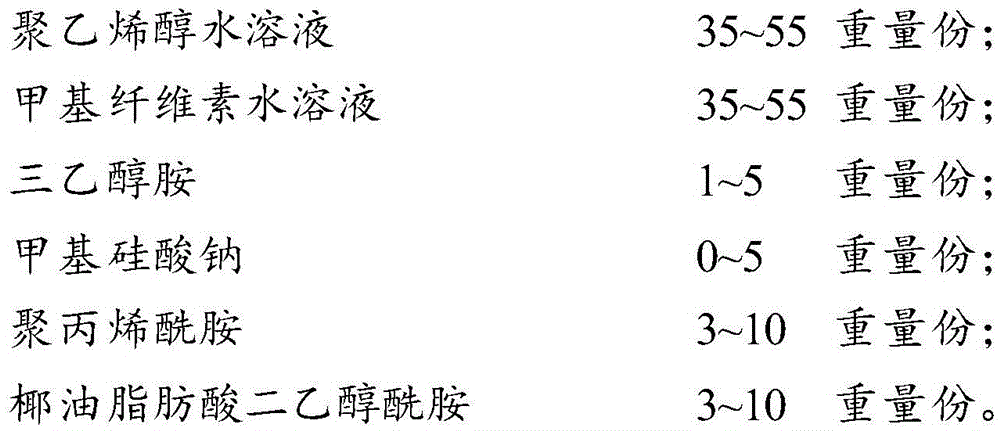

[0072] First weighed by mass fraction, 100 parts of cement, 0.1 part of polypropylene fiber, 10 parts of fly ash, 50 parts of tailings sand, 3 parts of waterproof reinforcing agent and 40 parts of water were evenly beaten to obtain prefabricated cement slurry; wherein, The specific formula of the waterproof enhancer is 40 parts by weight of polyvinyl alcohol aqueous solution, 30 parts by weight of methyl cellulose aqueous solution, 2 parts by weight of triethanolamine, 3 parts by weight of sodium methyl silicate, 7 parts by weight of polyacrylamide and 8 parts by weight. The coconut oil fatty acid diethanolamide of weight part.

[0073] At the same time, the ceramsite is subjected to anti-water absorption pretreatment, and the ceramsite is soaked in 801 construction glue, then taken out, and the glue is filtered off.

[0074] Then the obtained prefabricated cement slurry and foaming agent are mixed and stirred at a weight ratio of 1:0.03 to obtain a composite slurry, and then ...

Embodiment 2

[0078] First weighed by mass fraction, 100 parts of cement, 0.2 parts of polypropylene fiber, 20 parts of fly ash, 40 parts of stone powder, 4 parts of waterproof enhancer and 50 parts of water are evenly beaten to obtain prefabricated cement slurry; The specific formula of the strengthening agent is 55 parts by weight of polyvinyl alcohol aqueous solution, 55 parts by weight of methylcellulose aqueous solution, 5 parts by weight of triethanolamine, 10 parts by weight of polyacrylamide and 10 parts by weight of coconut oil fatty acid diethanolamide.

[0079] At the same time, the ceramsite is subjected to anti-water absorption pretreatment, and the ceramsite is soaked in 801 construction glue, then taken out, and the glue is filtered off.

[0080] Then the obtained prefabricated cement slurry and foaming agent are mixed and stirred at a weight ratio of 1:0.03 to obtain a composite slurry, and then 45 parts of ceramsite are mixed. The specific steps are: (1) the cement composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal insulation coefficient | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com