Super graphene glass, and preparation method and applications thereof

A graphene and quartz glass technology, applied in the field of materials, can solve the problems of reducing the quality of the film, complicated processes, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

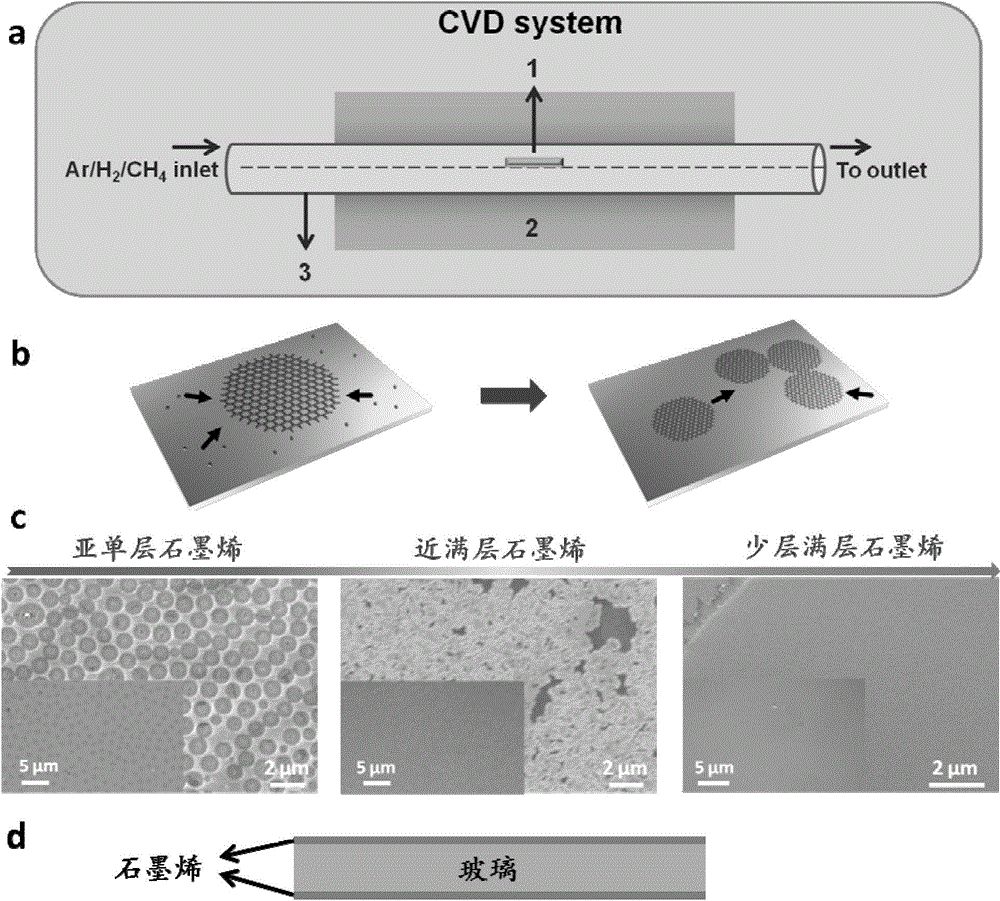

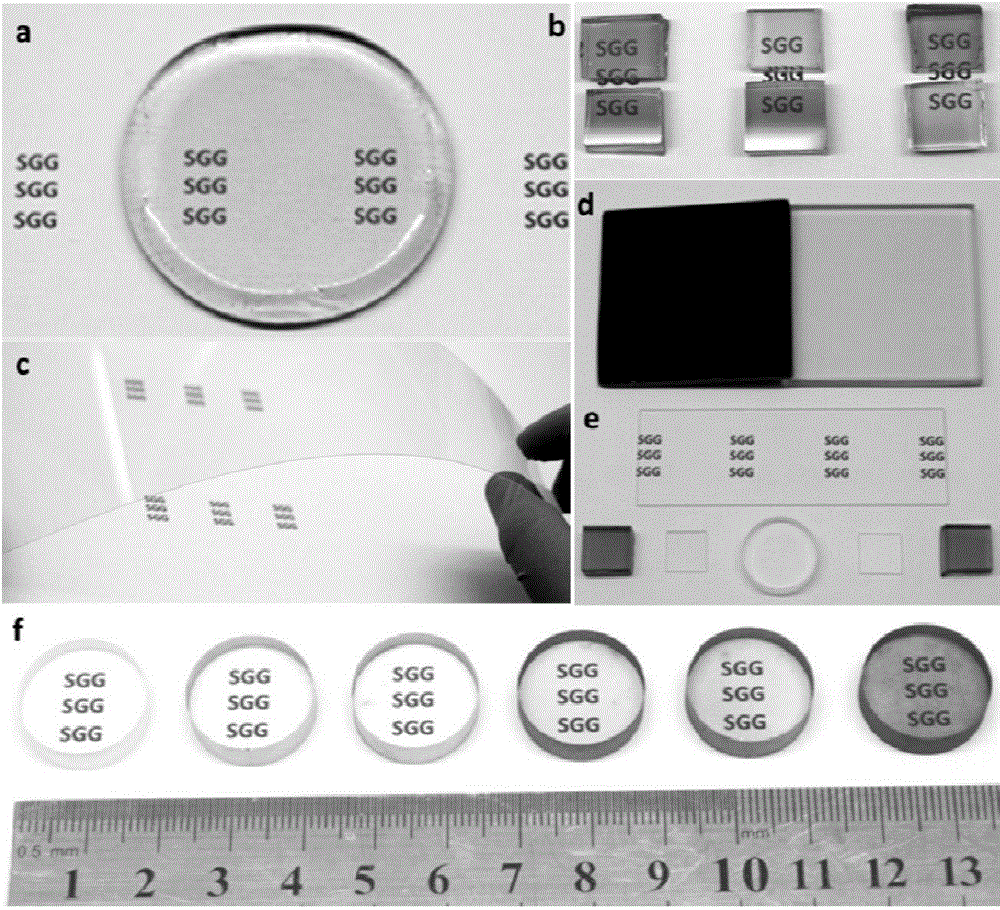

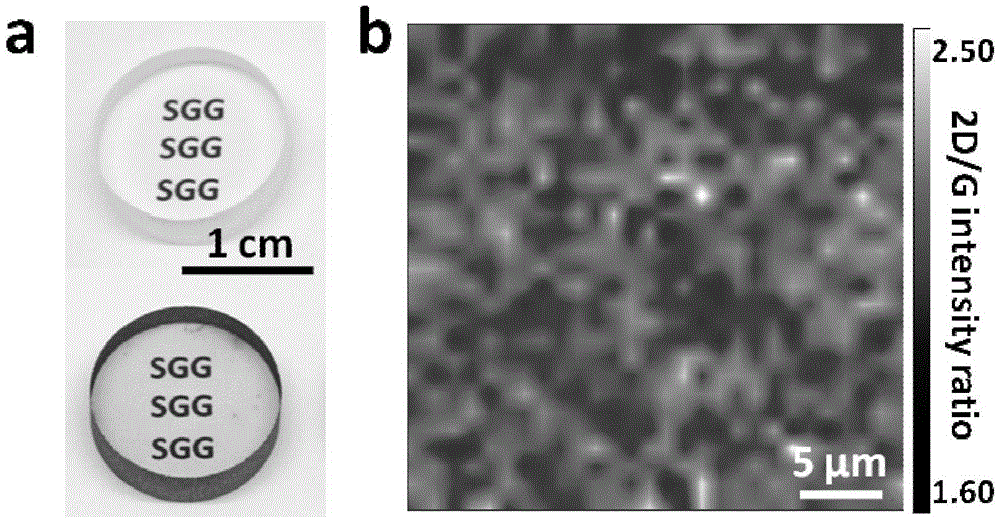

[0050] Embodiment 1. Using quartz glass as a substrate, super graphene glass was prepared by atmospheric pressure thermal chemical vapor deposition (APCVD), demonstrating its biocompatible properties of supporting cell growth.

[0051] 1) The quartz glass disc substrate (radius 1.5cm, thickness 4mm) was ultrasonically cleaned (ultrasonic bath) in ultrapure water, isopropanol, acetone and ultrapure water for 5 minutes each, and the ultrasonic power of the ultrasonic bath was 80W. The quartz glass substrate after the ultrasonic bath was blown dry with high-purity nitrogen to obtain a quartz glass substrate, which was set aside.

[0052] 2) Put the quartz glass substrate obtained after cleaning into the APCVD cavity, and put Ar and H 2 The gas flow meters are set to 100sccm and 50sccm respectively, and the Ar and H 2 Valve, for scrubbing process, the purpose is to get rid of H in the reaction chamber 2 O and O 2 , and the duration is 10 minutes. After the gas scrubbing is com...

Embodiment 2

[0062] Example 2. Using ordinary white glass as a substrate, graphene glass was prepared by molten-state APCVD, and its conductive properties were demonstrated.

[0063] 1) According to the method in step 1 of Example 1, the quartz glass was replaced with common white glass (both length and width were 5 cm, and the thickness was 4 mm), to obtain a clean common white glass substrate.

[0064] 2) Put the ordinary white glass substrate obtained after cleaning into a cube graphite crucible, then put the crucible into an APCVD cavity, and put Ar and H 2 The gas flow meters are set to 150sccm and 20sccm respectively, and the Ar and H 2 Valve, for scrubbing process, the purpose is to get rid of H in the reaction chamber 2 O and O 2 , and the duration is 10 minutes. After the gas washing is completed, the air pressure of the APCVD chamber is 1 atmosphere, and the ordinary white glass substrate is heated up to 1000°C, and Ar and H are kept during the heating process. 2 The flow rat...

Embodiment 3

[0070] Example 3. Using ordinary white glass as a substrate, graphene glass was prepared by plasma-enhanced chemical vapor deposition (PECVD), and its surface hydrophobicity was demonstrated.

[0071] 1) According to the method in Step 1 of Example 1, replace the quartz glass with common white glass (3 cm in length, 1 cm in width, and 4 mm in thickness) to obtain a clean common white glass substrate.

[0072] 2) Put the ordinary white glass obtained after cleaning as the substrate into the PECVD chamber, evacuate to 1Pa, and pass CH 4 Gas (5.5sccm), ordinary white glass substrate is heated up to 600°C, and the pressure of the controlled gas does not exceed 40Pa. When the system is stable, turn on the plasma power supply of 80W and react for 1 hour. Methane ionizes and cracks into active groups. The active groups on the surface of the substrate at 600°C react, carbon and carbon form bonds, and graphene grows directly. After the reaction is completed Turn off the plasma power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com