Surface ultrasonic scale prevention and removal system for solar photovoltaic panel

A solar photovoltaic panel, anti-scaling and descaling technology, applied in the direction of photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the cleaning frequency season, water source, personnel and technical maturity constraints, high cost of making photovoltaic panel guide grooves, The high price of cleaning robots has achieved broad prospects for application and promotion, improving power generation efficiency and service life, and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

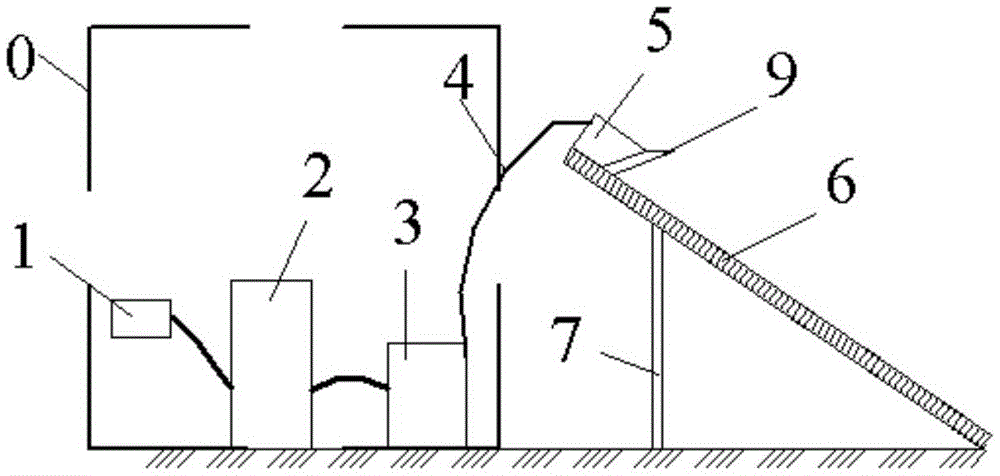

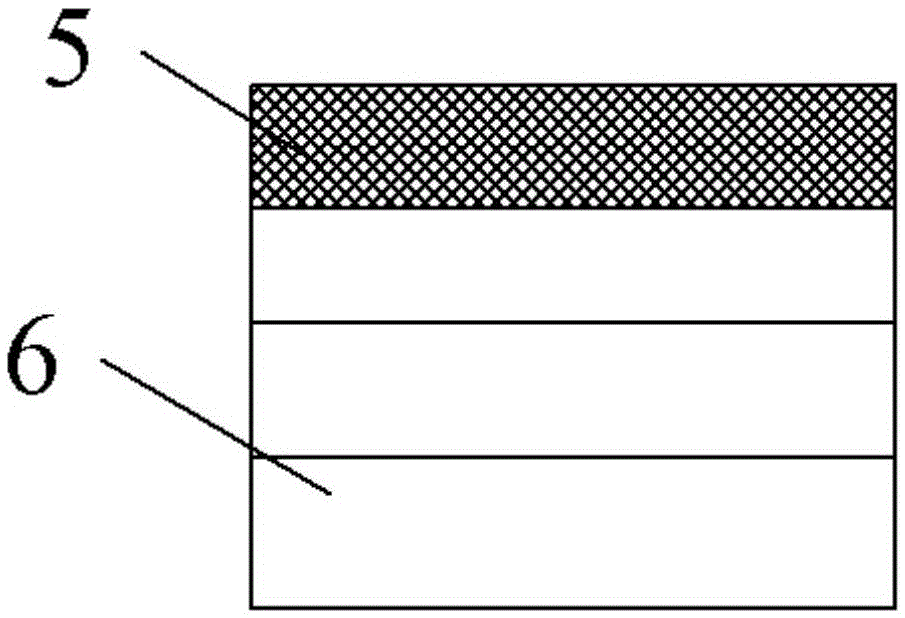

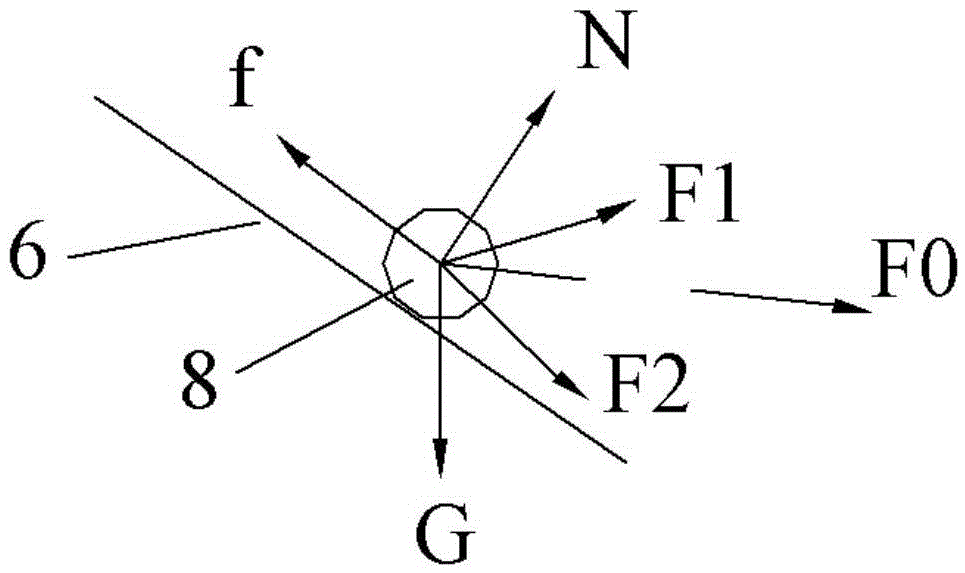

[0025] Such as Figure 1-3 As shown, an ultrasonic anti-scaling and descaling system on the surface of a solar photovoltaic panel of the present invention includes: a cabinet body 0, a photovoltaic DC power supply 1 with remote controllable lighting, an inverter 2, and an ultrasonic generator 3 are built in the cabinet body 0 , the remote controllable photovoltaic DC power supply 1, the inverter 2, and the ultrasonic generator 3 are electrically connected, the ultrasonic generator 3 is electrically connected to the ultrasonic energy converter 5 through the ultrasonic signal transmission cable 4, and the ultrasonic energy converter 5 is placed on the solar On the upper part of the photovoltaic panel 6 , the solar photovoltaic panel 6 is obliquely fixed on the photovoltaic panel support 7 . An ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com