LPG-related tank car cleaning device and method based on pressure swing adsorption technology

A pressure swing adsorption and cleaning device technology, applied in cleaning methods and appliances, membrane technology, separation methods, etc., can solve the problems of expensive, not economical and efficient cleaning methods, short life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

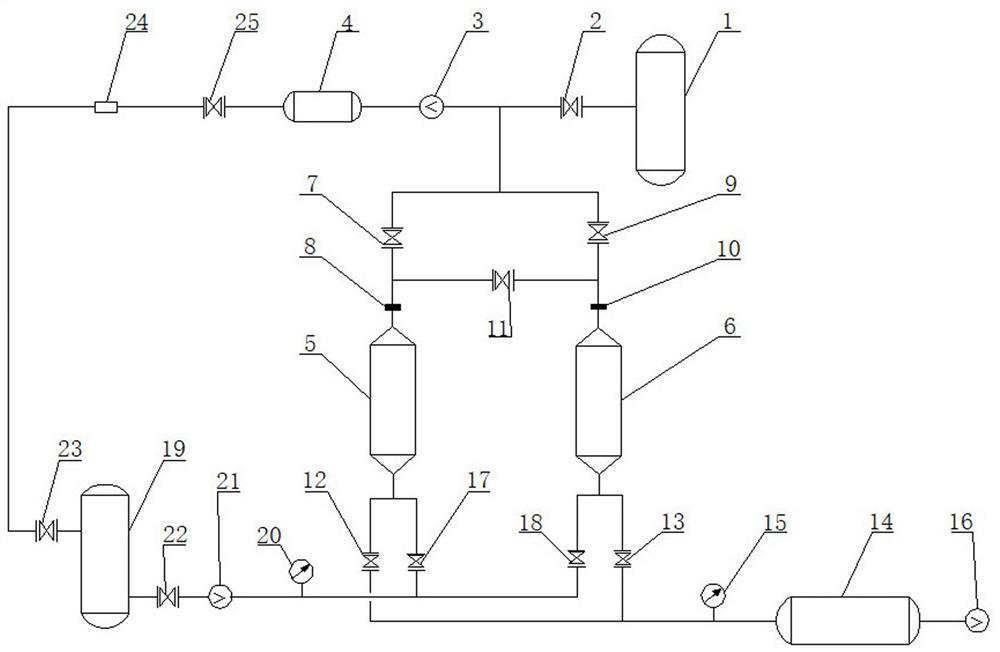

[0017] see figure 1 , the present invention is based on pressure swing adsorption technology and involves LPG tank car cleaning device, including liquid nitrogen tank, buffer tank, two adsorption towers, raffinate tank and purge nozzle, purge program control and interlock control, the liquid nitrogen The tank 1 is connected to the inlet of the LPG tank car 4 through the eighth electromagnetic valve 2 and the fan 3 through the pipeline, and is connected to the outlet of the first adsorption tower 5 and the second adsorption tower 6 through pipelines between the eighth electromagnetic valve 2 and the fan 3, The outlet pipes of the first adsorption tower 5 and the second adsorption tower 6 are correspondingly equipped with a sixth solenoid valve 7, a first VOCs concentration on-line detector 8, a seventh solenoid valve 9, and a second VOCs concentration on-line detector 10, respectively. The sixth solenoid valve 7 and the first VOCs concentration on-line detector 8, the seventh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com