g-C3N4/TiO2 composite photochemical catalyst and preparation method thereof

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of restricting the transport of photogenerated electrons and holes, the accumulation of photogenerated electrons and holes cannot be effectively utilized, the influence of photocatalyst activity and stability, etc. Conducive to large-scale preparation, improved quantum efficiency, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

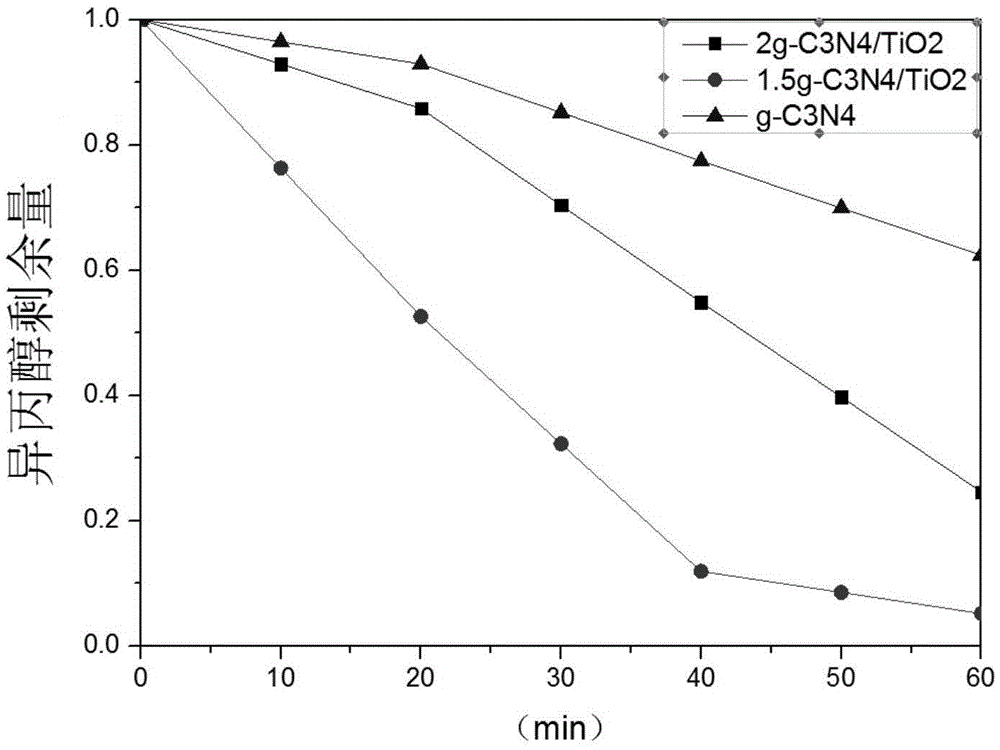

[0033] Embodiment 1 A kind of g-C 3 N 4 / TiO 2 Composite photocatalyst (g-C 3 N4 and TiO 2 The mass ratio is 2:1)

[0034] The preparation method is as follows:

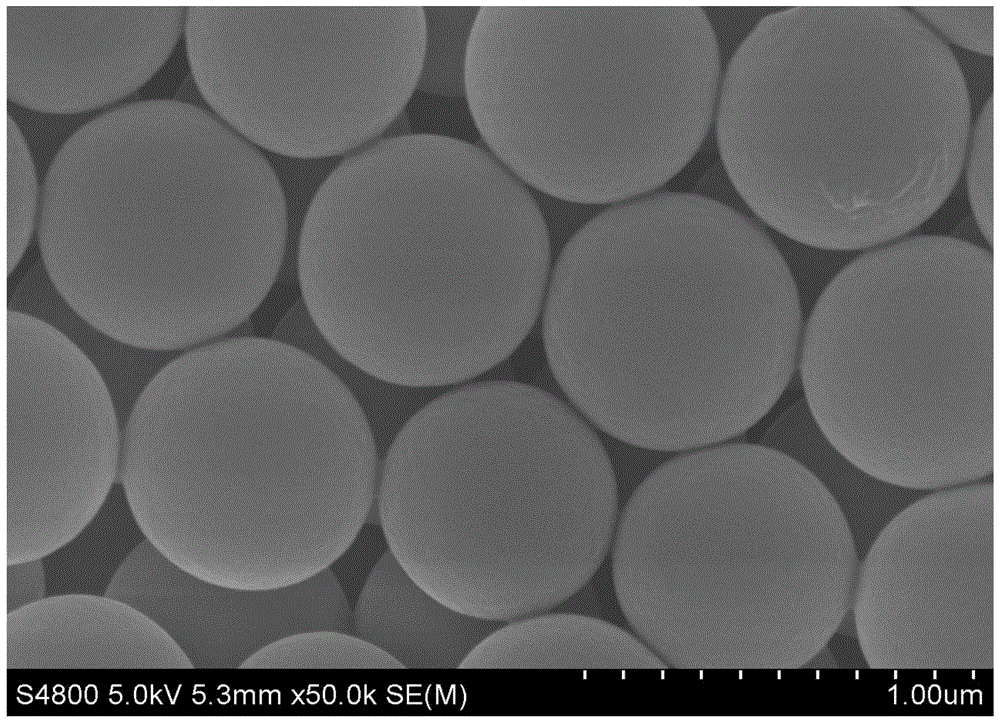

[0035] 1) Mix 3g of tetra-n-butyl titanate, 0.2g of triethanolamine and 20ml of absolute ethanol, and record it as solution B; ultrasonically disperse 0.5g of PS balls in 60ml of absolute ethanol, ultrasonically disperse for 1 hour, and then add 0.5ml of Ammonia, denoted as solution A; then the solution B that was stirred until transparent was added dropwise to solution A, and stirred for 2 hours to obtain TiO with a core-shell structure. 2 PS ball;

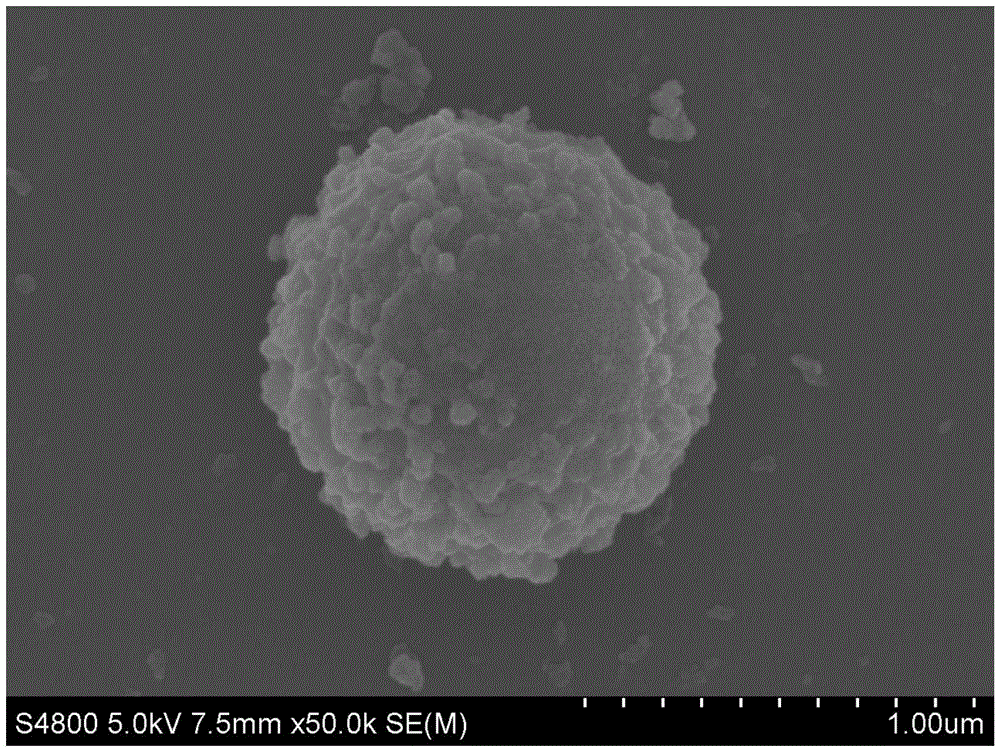

[0036] 2) Obtain TiO from 1) 2 PS spheres were dispersed in 60ml of methanol solution, which was recorded as solution C; 1.4gg-C 3 N 4 Ultrasonic dispersion in 200ml of methanol solution, recorded as solution D; solution C that has been ultrasonically dispersed for 1 hour was added drop by drop to solution D that had been ultrasonically dispersed for 1 hour, an...

Embodiment 2

[0041] Embodiment 2 A kind of g-C 3 N 4 / TiO 2 Composite photocatalyst (g-C 3 N 4 with TiO 2 The mass ratio is 1.5:1)

[0042] The preparation method is as follows:

[0043] 1) Mix 3g of tetra-n-butyl titanate, 0.2g of triethanolamine and 20ml of absolute ethanol, and record it as solution B; ultrasonically disperse 0.5g of PS balls in 60ml of absolute ethanol, ultrasonically disperse for 1 hour, and then add 0.5ml of Ammonia, denoted as solution A; then the solution B that was stirred until transparent was added dropwise to solution A, and stirred for 2 hours to obtain TiO with a core-shell structure. 2 PS ball;

[0044] 2) Obtain TiO from 1) 2 PS spheres were dispersed in 60ml of methanol solution, which was recorded as solution C; 1.05gg-C 3 N 4 Ultrasonic dispersion in 200ml of methanol solution, recorded as solution D; solution C that has been ultrasonically dispersed for 1 hour was added drop by drop to solution D that had been ultrasonically dispersed for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com