Preparation method of catalyst for reforming of methane and carbon dioxide to prepare syngas

A carbon dioxide and catalyst technology, which is applied in the field of preparation of a supported nickel-based catalyst for the reforming of methane and carbon dioxide to syngas, can solve the problems of accelerating the deep oxidation of the product, increasing the cost of the catalyst, and making little contribution of the catalyst, and improving the conversion rate and the product. selectivity, avoid further oxidation, reduce catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

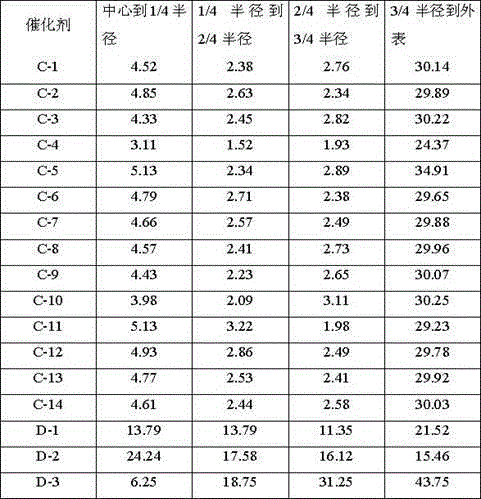

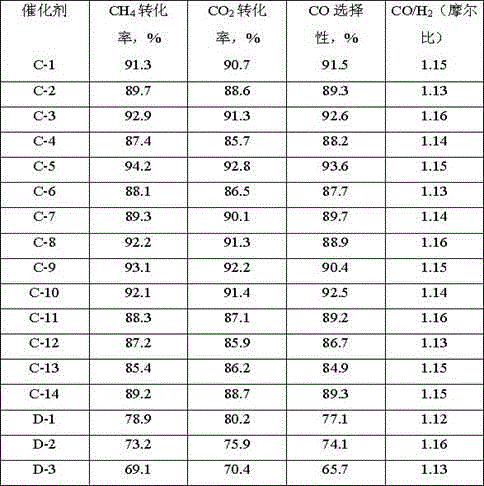

Image

Examples

Embodiment 1

[0030] Weigh 2.97g of nickel nitrate and 1.98g of cobalt nitrate and dissolve them in an appropriate amount of deionized water to obtain solution A; use an equal volume impregnation method to load 20g of alumina (pore volume 0.72ml / g, specific surface area 242m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to prepare catalyst precursor B, in which Ni accounted for 3% of the weight of the carrier by element and Co by element Accounting for 2% of the weight of the carrier; catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450 ° C, 0.2 MPa (absolute pressure), and the reduction time is 4 hours; after the reduction activation The catalyst precursor B and 300mL of sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced with hydrogen for 3 t...

Embodiment 2

[0032] Weigh 2.97g of nickel nitrate and 1.98g of cobalt nitrate and dissolve them in an appropriate amount of deionized water to obtain solution A; use equal volume impregnation method to load 20g of silicon oxide (pore volume is 1.06ml / g, specific surface area is 387m 2 / g, spherical, equivalent diameter 0.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to obtain catalyst precursor B, in which Ni accounted for 3% of the weight of the support as an element, and Co accounted for The weight of the carrier is 2%; the catalyst precursor B is activated in a mixed atmosphere containing hydrogen. Catalyst precursor B and 300mL sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced with hydrogen for 3 times, then adjusted the hydrogen pressure to 3MPa, and reacted at 220°C for 4h; After the mixture was placed for 2h, filtered, the resulting solid sample was dried at room temperature until ...

Embodiment 3

[0034] Weigh 2.97g of nickel nitrate and 1.98g of cobalt nitrate and dissolve them in an appropriate amount of deionized water to obtain solution A; use equal volume impregnation method to load 20g of SBA-15 (pore volume is 1.23ml / g, specific surface area is 701m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to prepare catalyst precursor B, in which Ni accounted for 3% of the weight of the carrier by element and Co by element Accounting for 2% of the weight of the carrier; catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450 ° C, 0.2 MPa (absolute pressure), and the reduction time is 4 hours; after the reduction activation The catalyst precursor B and 300mL of sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced with hydrogen for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com