Stable ixabepilone pharmaceutical composition

A technology of ixabepilone and composition, applied in the field of ixabepilone pharmaceutical composition and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

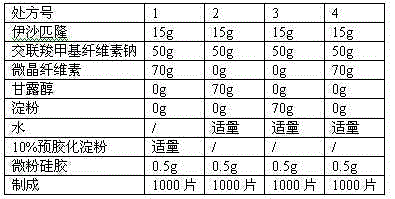

[0033] The formulation of ixabepilone made into 1000 tablets is as follows:

[0034] Ixabepilone 15g

[0035] Croscarmellose Sodium 50g

[0036] Microcrystalline cellulose 70g

[0037] Micropowder silica gel 0.5g

[0038] Appropriate amount of 10% pregelatinized starch solution

[0039] Preparation

[0040] 1) Ixabepilone, croscarmellose sodium and microcrystalline cellulose were dried, pulverized, and passed through a 100-mesh sieve to obtain ixabepilone powder, croscarmellose sodium and microcrystalline cellulose respectively. Cellulose powder;

[0041] 2) Take the prescribed amount of ixabepilone, croscarmellose sodium and microcrystalline cellulose, mix well, then add 10% pregelatinized starch solution to make a soft material, pass through a 40-mesh sieve to granulate , to obtain ixabepilone wet granules;

[0042] 3) Dry the above-mentioned ixabepilone wet granules at 60°C until the water content is less than 5%, to obtain ixabepilone dry granules

[0043] 4) Pass ...

Embodiment 2

[0045] The formulation of ixabepilone made into 1000 tablets is as follows:

[0046] Ixabepilone 45g

[0047] Croscarmellose Sodium 100g

[0048] Microcrystalline cellulose 140g

[0049] Micropowder silica gel 1g

[0050] Appropriate amount of 10% pregelatinized starch solution

[0051] Preparation

[0052] 1) Ixabepilone, croscarmellose sodium and microcrystalline cellulose were dried, pulverized, and passed through a 100-mesh sieve to obtain ixabepilone powder and microcrystalline cellulose powder respectively;

[0053] 2) Take the prescribed amount of ixabepilone, croscarmellose sodium and microcrystalline cellulose, mix well, then add 10% pregelatinized starch solution to make a soft material, pass through a 40-mesh sieve to granulate , to obtain ixabepilone wet granules;

[0054] 3) drying the above-mentioned ixabepilone wet granules at 60°C until the water content is less than 5%, to obtain ixabepilone dry granules;

[0055] 4) Pass the above-mentioned dry ixabepi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com