A kind of capacitor element composite material and preparation method thereof

A composite material and capacitor technology, applied in the field of materials, can solve problems such as unstable energy output, and achieve the effects of excellent cycle stability, good reversibility, and high specific capacitance value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

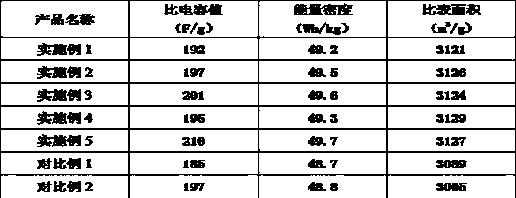

Examples

Embodiment 1

[0024] A capacitor element composite material, prepared from the following components in parts by weight: 2 parts of graphene oxide, 10 parts of xylitol, 50 parts of lignin, 1 part of tea saponin, 0.1 part of sorbic acid, 50 parts of sucrose, diced 0.5 parts of hydroxyanisole, 0.4 parts of 2,6-di-tert-butyl-p-cresol, 1 part of n-butyl stearate, 3 parts of isopropanol, 5 parts of concentrated hydrochloric acid, 10 parts of potassium hydroxide, sodium hydroxide 10 parts, 200 parts of distilled water.

[0025] The preparation method of the above capacitor element composite material is as follows: (1) mix graphene oxide, xylitol, lignin, sucrose and 150 parts of distilled water, and stir for 3 hours; (2) put it into a hydrothermal reaction kettle and heat to 200 ℃ for 12 hours; (3) cooled to room temperature, filtered, and washed with distilled water until neutral; (4) placed in an oven and dried at 110°C for 22 hours to obtain product A; (5) product A, hydrogen Potassium oxide, ...

Embodiment 2

[0027] A capacitor element composite material, prepared from the following components in parts by weight: 3.5 parts of graphene oxide, 15 parts of xylitol, 65 parts of lignin, 1.5 parts of tea saponin, 0.2 part of sorbic acid, 60 parts of sucrose, diced 0.75 parts of hydroxyanisole, 0.6 parts of 2,6-di-tert-butyl-p-cresol, 1.5 parts of n-butyl stearate, 4.5 parts of isopropanol, 7.5 parts of concentrated hydrochloric acid, 10-20 parts of potassium hydroxide, hydrogen Sodium oxide 15 parts, distilled water 250 parts.

[0028] The preparation method of the above capacitor element composite material is as follows: (1) Mix graphene oxide, xylitol, lignin, sucrose and 200 parts of distilled water and stir for 3.5 hours; (2) Put it into a hydrothermal reaction kettle and heat it to 225 ℃ for 12.5 hours; (3) cooled to room temperature, filtered, and washed with distilled water until neutral; (4) placed in an oven and dried at 115°C for 23 hours to obtain product A; (5) product A, hyd...

Embodiment 3

[0030] A capacitor element composite material, which is prepared from the following components in parts by weight: 5 parts of graphene oxide, 20 parts of xylitol, 80 parts of lignin, 2 parts of tea saponin, 0.3 parts of sorbic acid, 70 parts of sucrose, diced 1 part of hydroxyanisole, 0.8 parts of 2,6-di-tert-butyl-p-cresol, 2 parts of n-butyl stearate, 6 parts of isopropanol, 10 parts of concentrated hydrochloric acid, 20 parts of potassium hydroxide, sodium hydroxide 20 parts, 300 parts of distilled water.

[0031] The preparation method of the above capacitor element composite material is as follows: (1) mix graphene oxide, xylitol, lignin, sucrose and 250 parts of distilled water, and stir for 4 hours; (2) put it into a hydrothermal reaction kettle and heat to 250 ℃ for 13 hours; (3) cooled to room temperature, filtered, and washed with distilled water until neutral; (4) placed in an oven and dried at 120°C for 24 hours to obtain product A; (5) product A, hydrogen Potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com