Hydraulic fracturing test apparatus based on conventional testing machine for rock mechanics, rock specimen and hydraulic fracturing testing method

A technology of rock mechanics and hydraulic fracturing, which is applied in the preparation of test samples, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of increasing experimental costs, reducing sample size, parallelism and perpendicularity. Advanced problems, to achieve the effect of improving operating efficiency and success rate, improving control and measurement accuracy, reducing cost and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

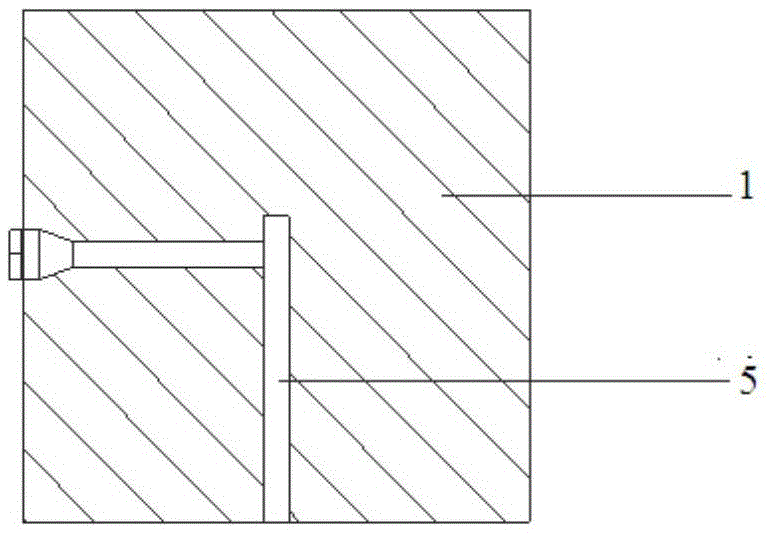

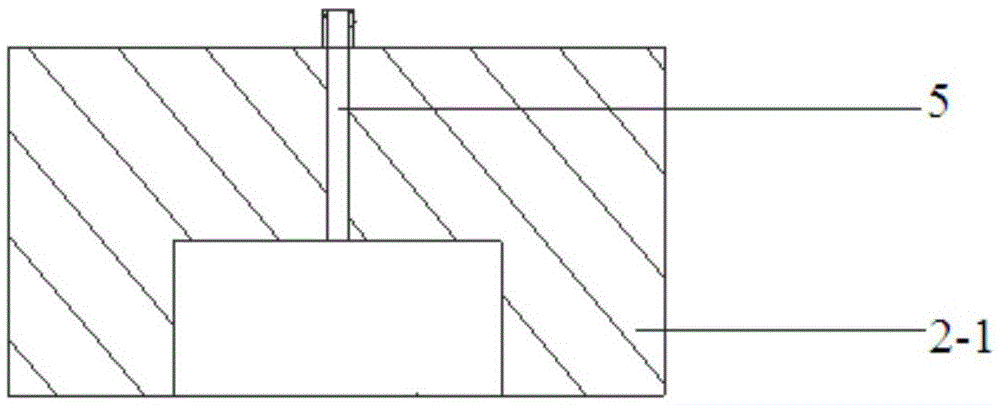

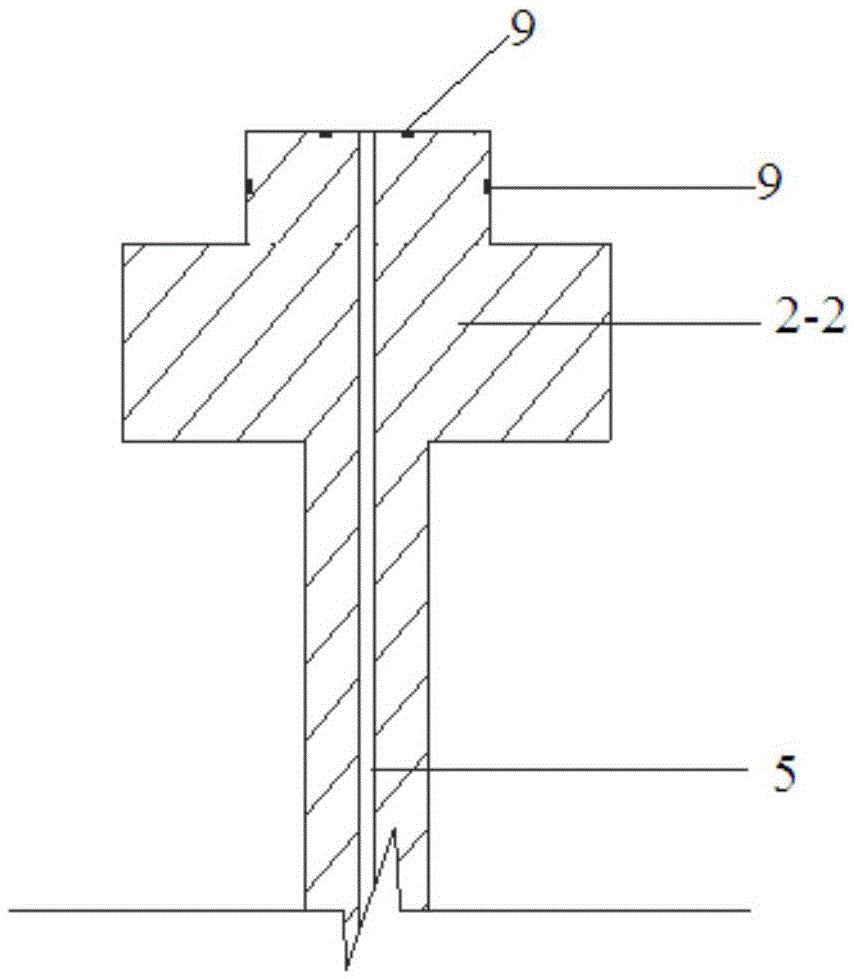

[0046] The structure of the device used to conduct hydraulic fracturing experiments on a conventional rock mechanics testing machine is as follows:

[0047] The upper pressure head 4 acted on by the lower pressure head 2 and the axial pressure rod 3 arranged on the chassis 1 of the triaxial chamber, and the elasticity of the pressure water 6 sleeved outside the rock sample to prevent the pressure water from mixing into the triaxial chamber ambient pressure oil 6 The anti-leak cover 7 of material and penetration plate 8 form. Both the upper pressure head and the lower pressure head are designed with a pressure water flow channel 5, and the upper and lower ends of the anti-leakage sleeve are fixed on the upper pressure head and the lower pressure head by tightening the sealing ring (obtained from the market); There is a pressure water seepage hole, which is arranged between the rock sample at the outlet of the pressure water and the indenter; the upper indenter is an integral st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com