Quick-detachable pin shaft structure for connecting guide holder with pedestal of large-size drilling machine

A guide seat and drilling rig technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of less rotation probability, easy to cause danger, easy to rust, etc., and achieve the effect of reasonable and ingenious structure, convenient disassembly of the pin shaft, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

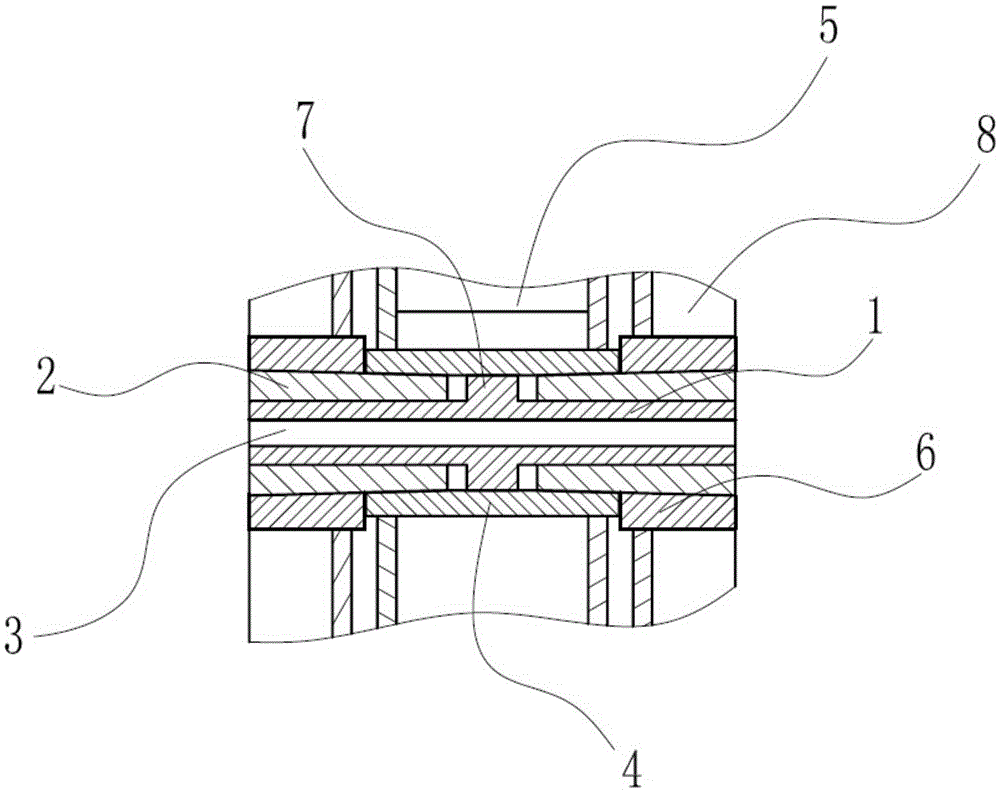

[0015] Such as figure 1 As shown, the embodiment of the present invention relates to a quick-detachable pin shaft structure connecting the guide seat and the base of a large drilling rig, including the base 8, the screw shaft 1 and the male seat 5 connected to the guide seat, and the male seat 5 is located on the base 8 Inside, the screw shaft 1 traverses through the inner hole of the base 8 and the male seat 5, and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com