A curb slipform machine

A sliding form machine and curb stone technology, applied in the field of road construction machinery, can solve the problems of high labor intensity, slow construction speed, and inability to clean in time, and achieve the effects of improving operation accuracy, reducing transition costs, and improving transition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

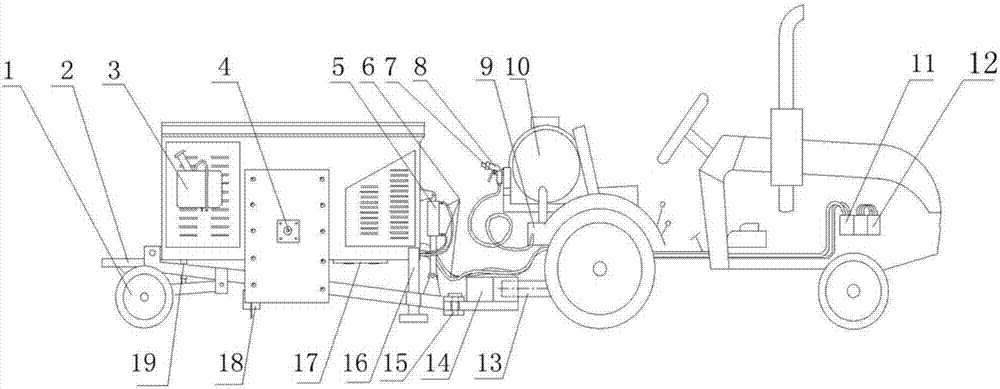

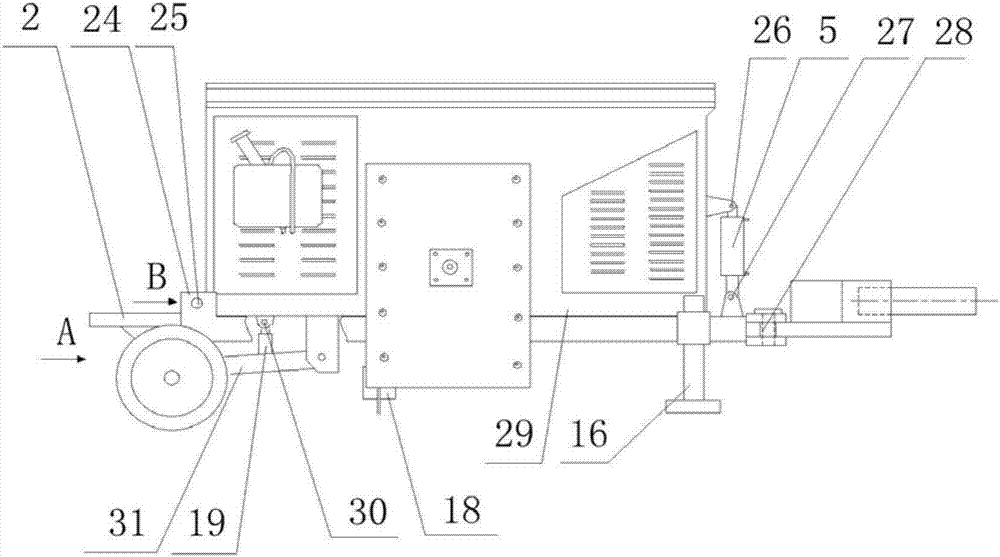

[0037] Such as Figure 1~5 As shown, a curb slipform machine includes a body 29, a frame 24 arranged on the body, a material conveying device, a material forming device, a power device, a walking device, a leveling device, a lifting device, the same as the body 29 connected traction device, the curb slipform machine also includes a remote control device arranged on the body 29, a steering device and a high-pressure cleaning device arranged on the traction device; the traction device is a tractor, and the tractor is self-refitted A 35-40 horsepower tractor with crawling gears, the tractor is connected with the body 29 through the drawbar 13 .

[0038] The front end of the body 29 is welded with a support column socket, and a support column 16 is installed in the support column socket, and the support column 16 is fixed on the body 29 with a fixing pin. When the unit is not working or needs to check and replace parts, the support column 16 is fixed by the fixed pin shaft, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com