Oblique crossing circular pipe intersection face inner insertion plate turning connection structure

A technology of oblique circular tubes and intersecting surfaces, which is applied in building construction, manufacturing tools, welding equipment, etc., can solve the problems of increasing mutual dependence, restraining the application of multi-limb space frame load-bearing steel pipe cylinders, and achieving welding. The effect of reducing space difficulty, direct and clear space force transmission path, and simplified internode force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

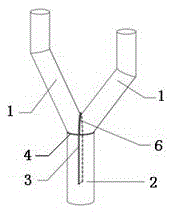

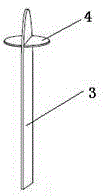

[0027] The oblique circular pipes in this embodiment are two oblique V-shaped limb pipes 1, and the two limb pipes 1 are connected with the vertical circular pipe pier 2 to form a Y-shaped column, such as figure 1 , 2 As shown, the intersecting plane at the oblique intersection of the two limb tubes 1 is axially and through-type inserted with a longitudinal adapter plate 3, the longitudinal adapter plate 3 picks out the intersecting surface radially, and the longitudinal adapter plate 3 Into the circular tube pier 2 extending below, the depth of the longitudinal adapter plate inserted into the column pier is max (600mm, 1.2×column pier diameter D), the longitudinal adapter plate 3 and the leg pipe 1, and the longitudinal adapter plate 3 and the cylindrical pier 2 are fixed by V-shaped full-penetration groove welding, and the grade of weld 6 is the first grade. At the same time, a transverse adapter plate 4 is provided at the joint between the oblique intersections of the two ...

Embodiment 2

[0029] The oblique circular pipes in this embodiment are two obliquely V-shaped limb pipes 1, and the two limb pipes 1 are connected with the X-forked circular pipe pier 5 to form an X-shaped column, as image 3 , 4 shown. In the intersecting plane of the oblique intersection of the two limb tubes 1, a longitudinal adapter plate 3 is inserted axially and through-type. The longitudinal adapter plate 3 picks out the intersecting surface radially, and the longitudinal adapter plate 3 extends axially to In the lower X-fork circular tube pier 5, the depth of the longitudinal adapter plate inserted into the column pier is max (600mm, 1.2×column pier diameter D), the longitudinal adapter plate 3 and the leg tube 1, and the longitudinal adapter plate 3 Both the pier and the X-fork round pipe pier 5 are fixed by V-shaped full-penetration groove welding, and the grade of the weld 6 is the first grade. At the same time, a transverse adapter plate 4 is provided at the junction of the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com