Construction method for 48m sectional beam of passenger railway based on BIM technology

A technology for passenger dedicated lines and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult to guarantee construction quality, high cost, slow construction progress of large-span beams, etc., to shorten the construction period and improve the construction. Efficient, easy-to-understand effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

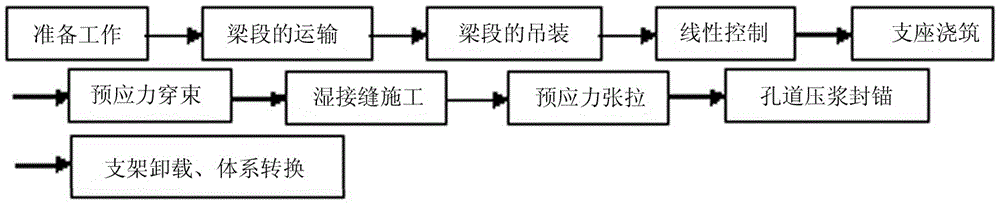

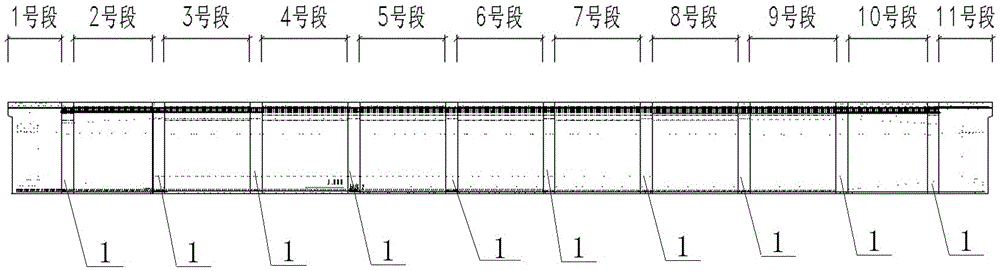

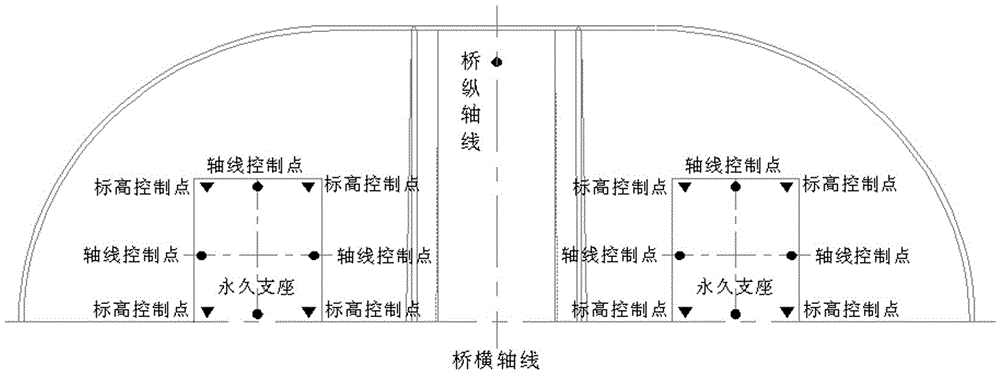

[0037] The 48m section beam construction method of the passenger dedicated line based on BIM technology described in the present invention is to divide the beam body into figure 2 The 11 sections (beam sections) shown are prefabricated in the factory and then transported to the bridge site to assemble them with a mobile support bridge erecting machine. The construction process of assembling the sections into a bridge by applying prestress is The bridge-building machine with mobile supports is the carrier for the assembly of prefabricated segments on the top of the pier. When assembling the segments, the bridge-building machine is moved to the spans of the girders to be assembled, and then the prefabricated segments transported from the prefabrication yard Lift and support it on the bridge-building machine, adjust the line shape and camber, carry out wet joint construction after passing through the steel strands, and finally stretch the prestress to complete the system conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com