Gripping device for transporting slide trays

A grabbing device and carrier disc technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of lack of stability and safety, low efficiency, inconvenient operation, etc., and achieve a simple and reliable structure. , The effect of stable and safe operation, uniform circumferential force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

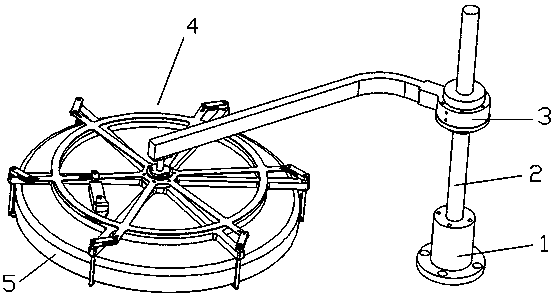

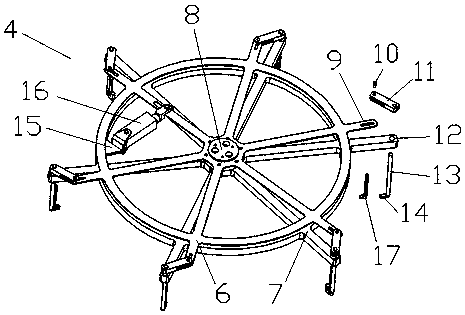

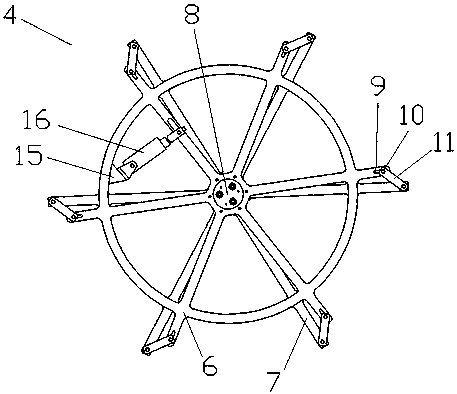

[0014] Embodiments of the present invention are further described below in conjunction with the accompanying drawings, Figure 1 to Figure 4 is a schematic illustration of the operation of an embodiment device according to the present invention. It should be understood that the disclosed Figure 1 to Figure 4 Emphasis is placed on illustrating components of devices according to embodiments of the present invention, that is, these figures are not intended to illustrate every single component of the device of the present invention.

[0015] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a grabbing device for chemical vapor deposition equipment transporting the carrier tray mainly includes a base 1, a guide rod 2, a rotary arm 3, and a manipulator 4. The guide rod 2 is fixedly installed on the base 1, and the rotary arm 3 is installed On the guide rod 2, the end of the rotary arm 3 is equipped with a manipulator 4 for grabbing and placing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com