Pressing block assembly, door assembly and clothes treating apparatus

A technology for a clothing treatment device and block assembly, which is applied to washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of low connection strength, easy loosening of door glass, etc., and achieves the effect of low cost, compact structure and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

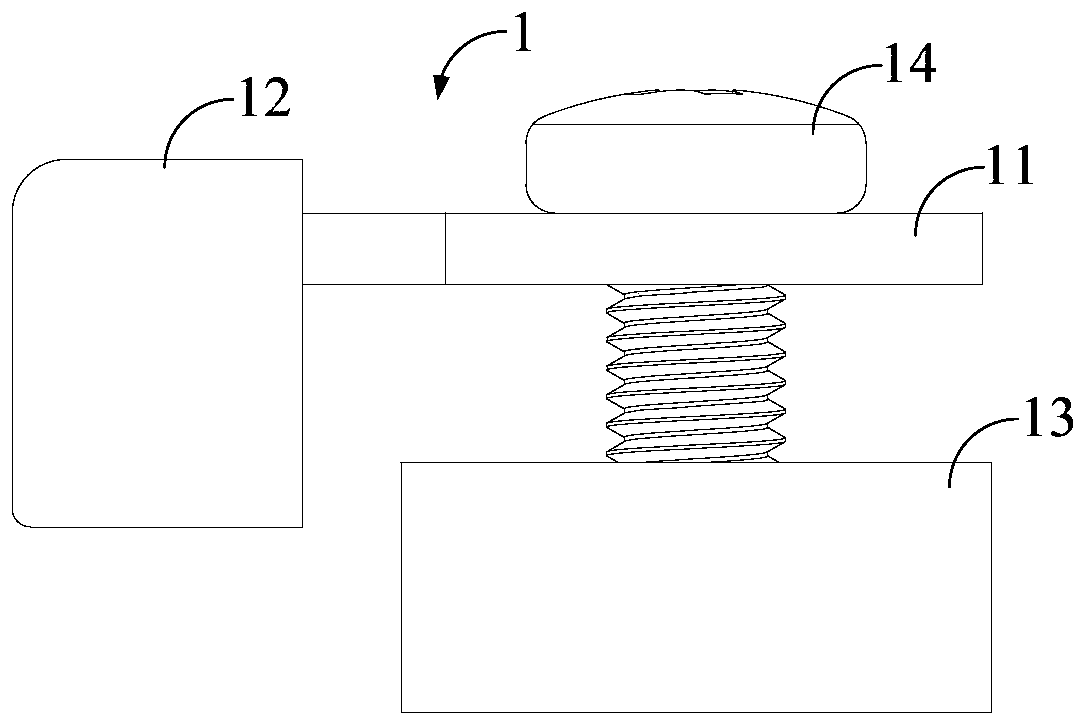

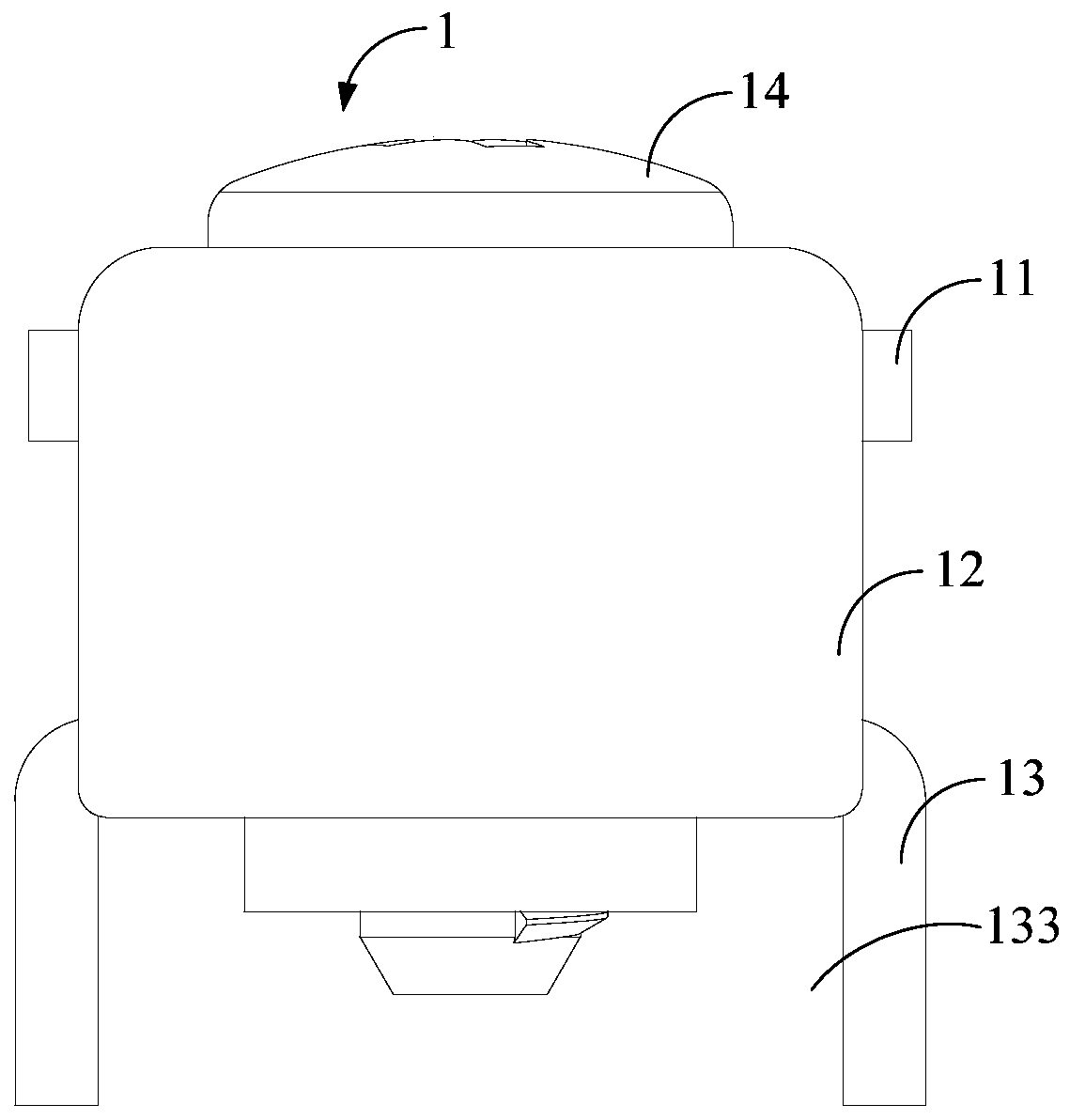

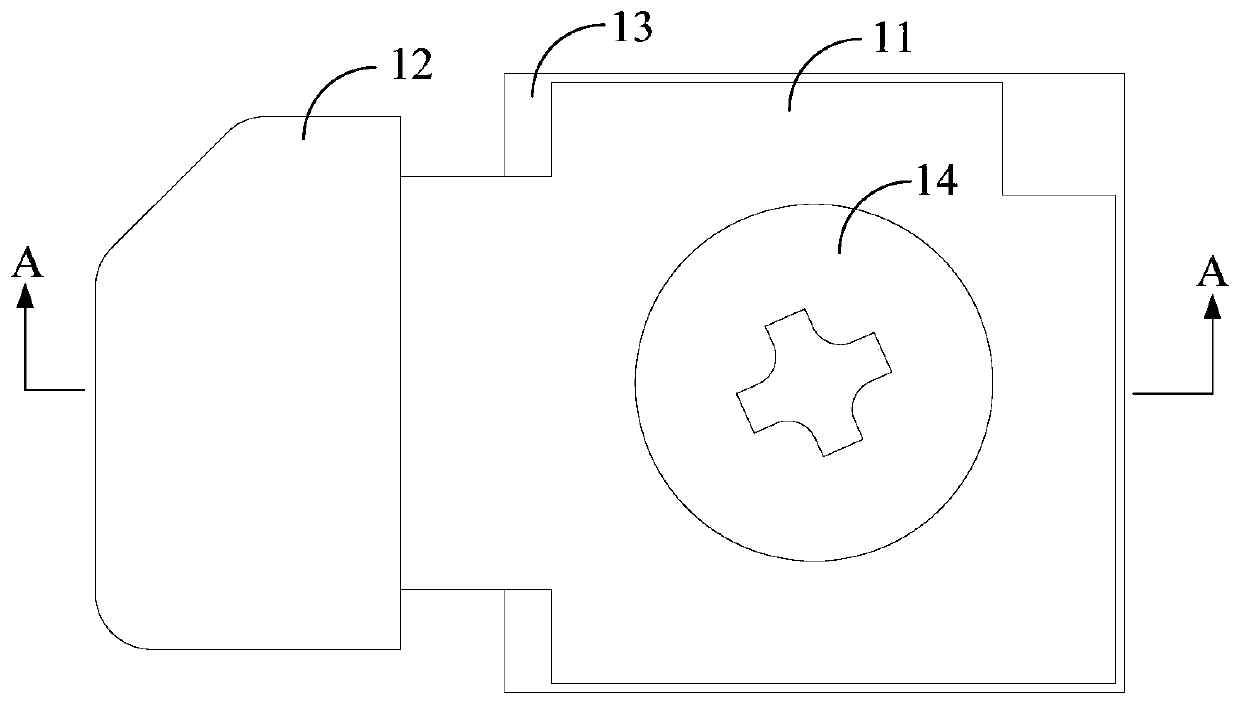

[0066] A briquetting block assembly 1, comprising: a connecting piece 11, a pressing piece 12 and a fixing piece 13, such as Figure 1 to Figure 4 shown.

[0067] Specifically, the pressing part 12 is connected with the connecting part 11, and is used for pressing the door glass 3 of the laundry treatment device on the inner ring 2 of the door, such as Figure 7 shown. One of the fixing part 13 and the connecting part 11 is provided with a through hole 111 for the threaded fastener 14 to pass through, and the other is a rigid member and is provided with a threaded hole 1311 corresponding to the through hole 111, the through hole 111 and the threaded hole 1311 is used to cooperate with the connection hole 23 on the door inner ring 2, such as Figure 7 As shown, the pressure block assembly 1 is fixedly connected to the door inner ring 2 through a threaded fastener 14 .

[0068] The pressing block assembly 1 provided by the embodiment of the first aspect of the present inventi...

Embodiment 2

[0095] The difference from Embodiment 1 is that: on the basis of Embodiment 1, further, the pressure block assembly 1 further includes: threaded fasteners 14, such as Figure 1 to Figure 4 shown. The threaded fastener 14 is threaded and fixed through the through hole 111 and the threaded hole 1311 .

[0096] The briquetting block assembly 1 also includes a threaded fastener 14, which is used in conjunction with the connecting piece 11 and the fixed connection, and has good adaptability, and when the briquetting block assembly 1 is not used, the threaded fastener 14 can The briquetting block assembly 1 is connected as a whole to prevent parts from being lost during transportation and storage of the briquetting block assembly 1 .

[0097] Of course, the pressure block assembly 1 may not include the threaded fastener 14 , and another suitable threaded fastener 14 is selected according to the size of the pressure block assembly 1 during the assembly process.

[0098] Optionally,...

Embodiment 3

[0100] The difference from Embodiment 1 or Embodiment 2 is that the through hole 111 is provided on the fixing member 13, the threaded hole 1311 is provided on the connecting member 11, and the main body of the door inner ring 2 is provided with a threaded fastener 14 to pass through. The avoidance hole, the threaded fastener 14 runs through the avoidance hole, the fixing member 13, the connecting plate 21 and the connecting member 11 in turn, so that the pressing block assembly 1 is fixedly connected with the door inner ring 2, and the door glass 3 is pressed on the door inner ring 2.

[0101] In other words, the installation direction of the threaded fastener 14 is opposite to that of the first or second embodiment.

[0102] Such as Figure 5 with Image 6 As shown, the door assembly of the laundry treatment device provided by the embodiment of the second aspect of the present invention includes: a door inner ring 2, a door glass 3 and the pressing block assembly 1 accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com