Mounting method of blast furnace hearth bottom temperature thermocouple

A technology of temperature measurement thermocouple and installation method, which is applied in inspection devices and other directions, can solve the problems that the thermocouple cannot truly reflect the temperature of carbon bricks and the measurement error of the thermocouple is large, so as to eliminate air gaps, prevent air gaps, and improve measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

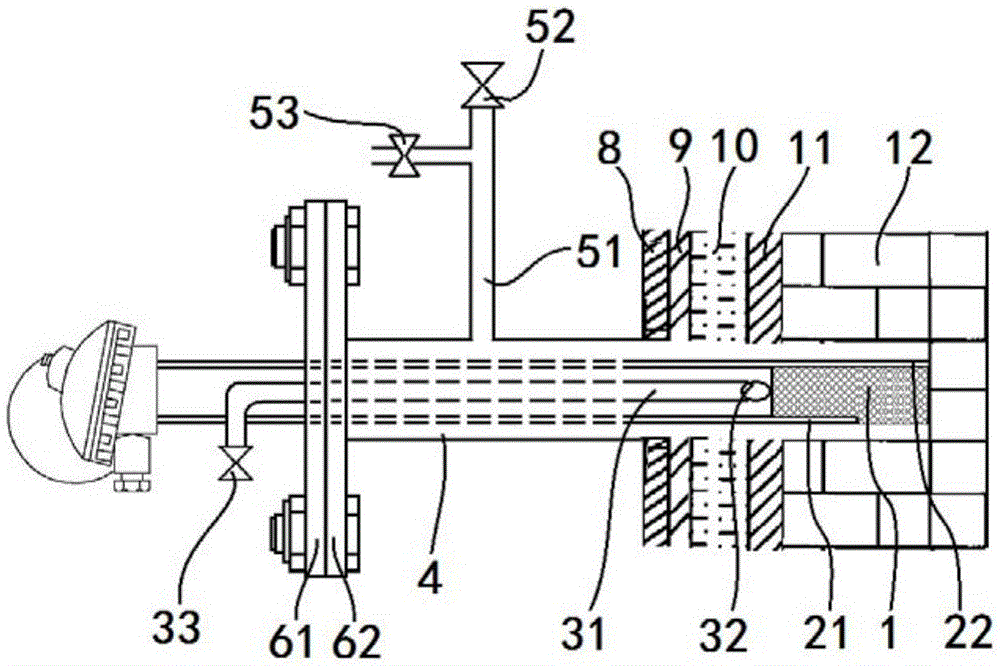

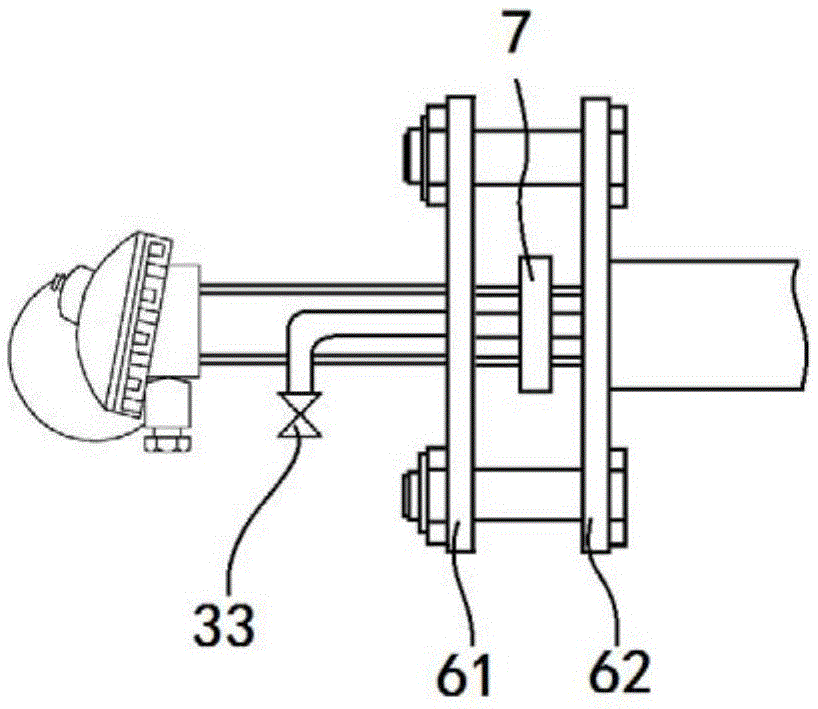

[0058] combine figure 1 , 2 , 3, 4, 5 and 7, a thermocouple online installation device for blast furnace temperature measurement of the present invention, including a grouting mechanism and a sealing mechanism, a grouting outlet is provided on the grouting mechanism, and the grouting outlet is used for grouting After the gap is filled, the excess slurry is discharged, and the slurry outlet is located at the end far away from the sealing mechanism; since the slurry outlet is located at the end far away from the sealing mechanism, the gas in the installation hole can be completely discharged during the process of filling the gap. , only when the slurry fills the entire gap, the slurry will flow out from the slurry outlet, preventing air gaps during the slurry filling process, thereby improving the accuracy of the thermocouple.

[0059] The grouting mechanism includes a grout inlet pipe 51 and a grout outlet pipe 31. The grout outlet pipe 31 is provided with a grout outlet pipe ...

Embodiment 2

[0123] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that: during the compaction process, close the slurry outlet valve 33, increase the grouting pressure to 0.08MPa, and keep it for 20 minutes; the outer casing 4 and the slurry inlet pipe 51 are provided with With matching internal and external threads, the outer casing 4 and the slurry inlet pipe 51 are threadedly connected, and the airtightness of the outer casing 4 and the slurry inlet pipe 51 is tested.

[0124] The horizontal distance between the first thermocouple 21 temperature measuring end face and the furnace skin 8 surface is 515mm, and the second thermocouple 22 is 565mm apart from the horizontal distance on the furnace skin 8 surface; the first thermocouple 21 temperature measuring end face and the second thermocouple 22 The horizontal distance between the end face of the temperature measuring end is 50mm. The horizontal distance between the first temperature meas...

Embodiment 3

[0129] The basic content of this embodiment is the same as that of Embodiment 1, except that: during the compaction process, the grouting valve 33 is closed, the grouting pressure is increased to 0.1 MPa, and maintained for 15 minutes. The horizontal distance between the first thermocouple 21 temperature measuring end face and the furnace skin 8 surface is 415mm, and the horizontal distance between the second thermocouple 22 and the furnace skin 8 surface is 565mm; the first thermocouple 21 temperature measuring end face and the second thermocouple 22 The horizontal distance between the end face of the temperature measuring end is 150mm. During installation, the horizontal distance between the first temperature measuring point and the surface of the furnace skin 8 is 415mm, the first temperature measuring point and the temperature measuring end face of the first thermocouple 21 are located at the same vertical position, and the second temperature measuring point is at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com