Artificial stone rough block curing process

A technology of artificial stone and blocks, which is applied in the field of artificial stone block maintenance technology, can solve the problems of resin instability, low thermal transition point, floor deformation, etc., and achieve the results of reducing internal cracks, stabilizing product performance, and good product performance effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

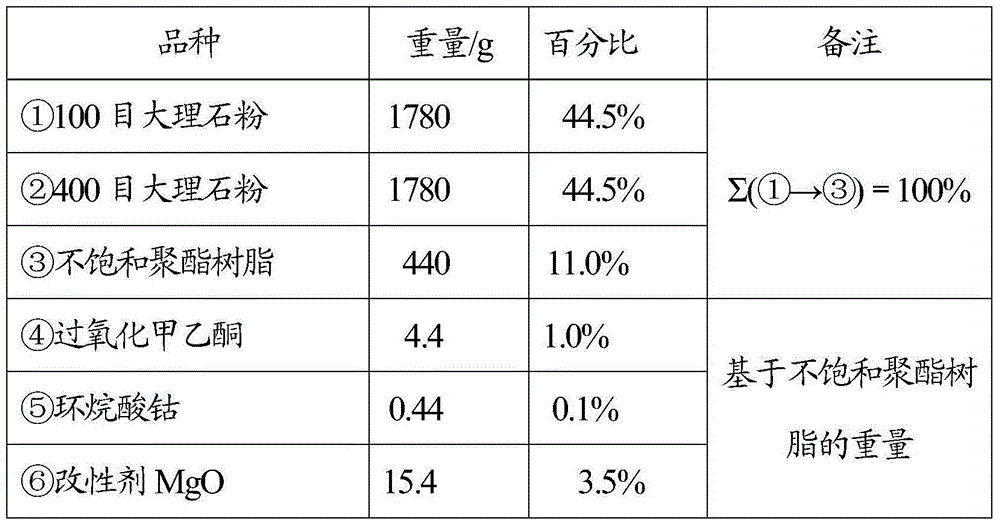

[0038] The preparation method of the aforesaid artificial stone blocks added with modifying agent comprises the steps:

[0039] Stir the unsaturated polyester resin as the binder with the curing agent system and then mix it with the stone, and then put the obtained artificial stone mud into the mold for molding, and the artificial stone mud is mixed with alkaline earth metal oxides and / or alkaline earth metal hydroxides.

[0040] Specifically include the following steps:

[0041] 1) stirring the unsaturated polyester resin and curing agent system;

[0042] 2) Stirring of graded filler stones;

[0043] 3) mixing and stirring the materials obtained in step 1) and step 2) respectively to form artificial stone mud;

[0044] 4) the artificial stone mud cloth cloth that step 3) obtains is in the mould;

[0045] 5) The artificial stone mud is vacuum-vibrated and pressed in the mold to form artificial stone blocks;

[0046]Wherein, there are two ways to add the modifying agent in...

Embodiment 1

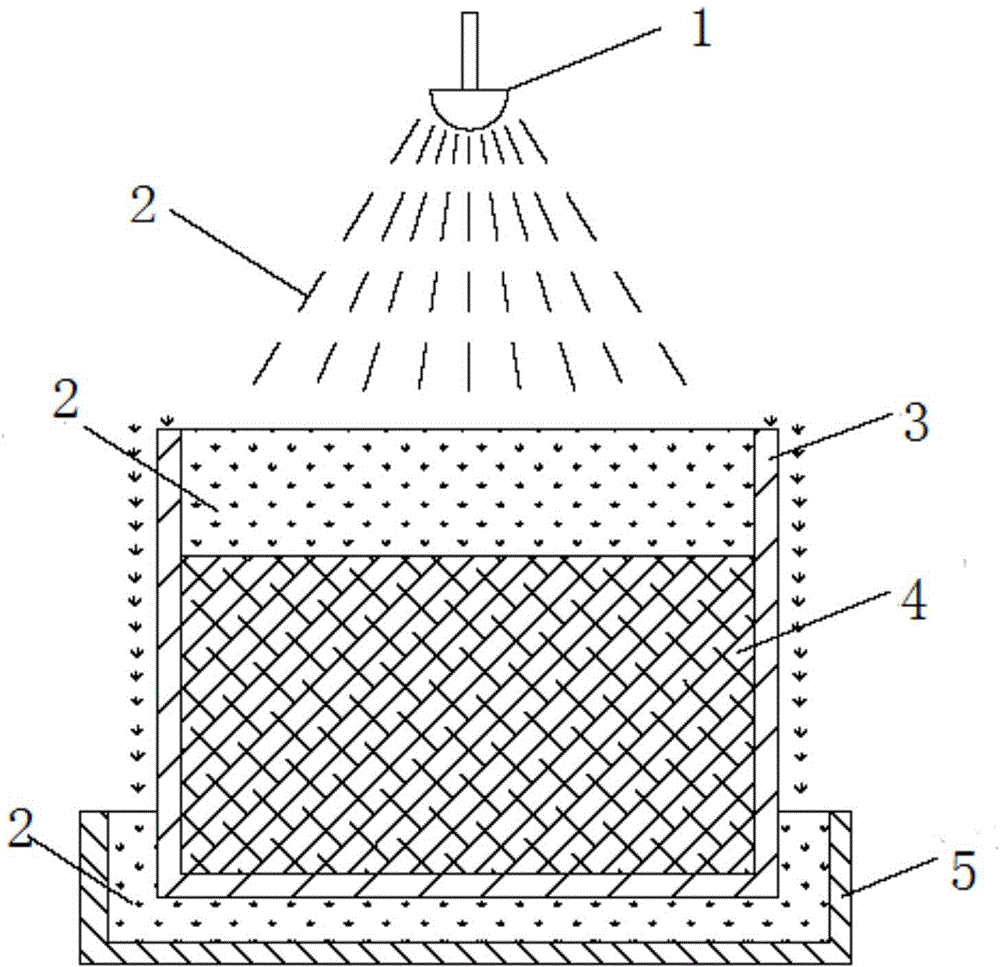

[0052] The artificial stone blocks maintenance process in the present embodiment comprises the following steps:

[0053] 1. Vibrating and pressing artificial stone blocks under vacuum conditions;

[0054] 2. The pressed artificial stone blocks are placed in the spray area for heating and curing;

[0055] Specifically: spray artificial stone blocks with hot water for 3 hours, and the temperature of the hot water is 99°C;

[0056] After spraying, recycle the warm water overflowing from the reservoir, heat it to a predetermined temperature, and then spray it into the block mold for recycling;

[0057] 3. Remaining at room temperature;

[0058] Continue to maintain the artificial stone blocks after heating and curing at room temperature, that is, stand at room temperature for 15 days;

[0059] 4. Then the artificial stone blocks are stripped. After the stripping, the artificial stone blocks are cut (opened), polished, sorted and packaged by a gang saw.

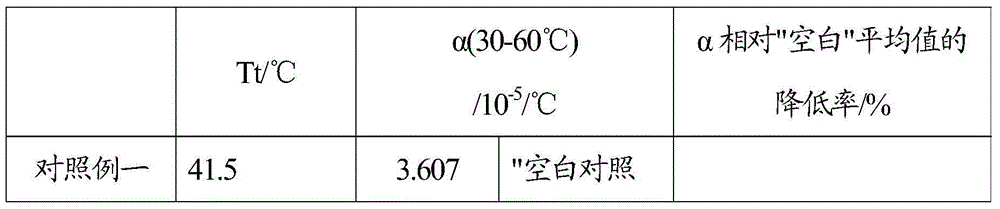

[0060] In this embodim...

Embodiment 2

[0062] The artificial stone blocks maintenance process in the present embodiment comprises the following steps:

[0063] 1. Vibrating and pressing artificial stone blocks under vacuum conditions;

[0064] 2. The pressed artificial stone blocks are placed in the spray area for heating and curing;

[0065] Specifically: Spray the artificial stone blocks with hot water for 15 hours, and the temperature of the hot water is 90°C;

[0066] After spraying, recycle the warm water overflowing from the reservoir, heat it to a predetermined temperature, and then spray it into the artificial stone block mold for recycling;

[0067] 3. Remaining at room temperature;

[0068] Continue to maintain the artificial stone blocks after heating and curing at room temperature, that is, stand at room temperature for 8 days;

[0069] 4. Then the artificial stone blocks are stripped. After the stripping, the artificial stone blocks are cut (opened), polished, sorted and packaged by a gang saw.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com