Manufacturing method of transparent microstructure

A manufacturing method and microstructure technology, applied in the post-processing of printing, printing, printing devices, etc., can solve the problems of missing patterns, limited types of ink, and slow printing speed, so as to reduce production costs, overcome irregular appearance, and improve The effect of production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

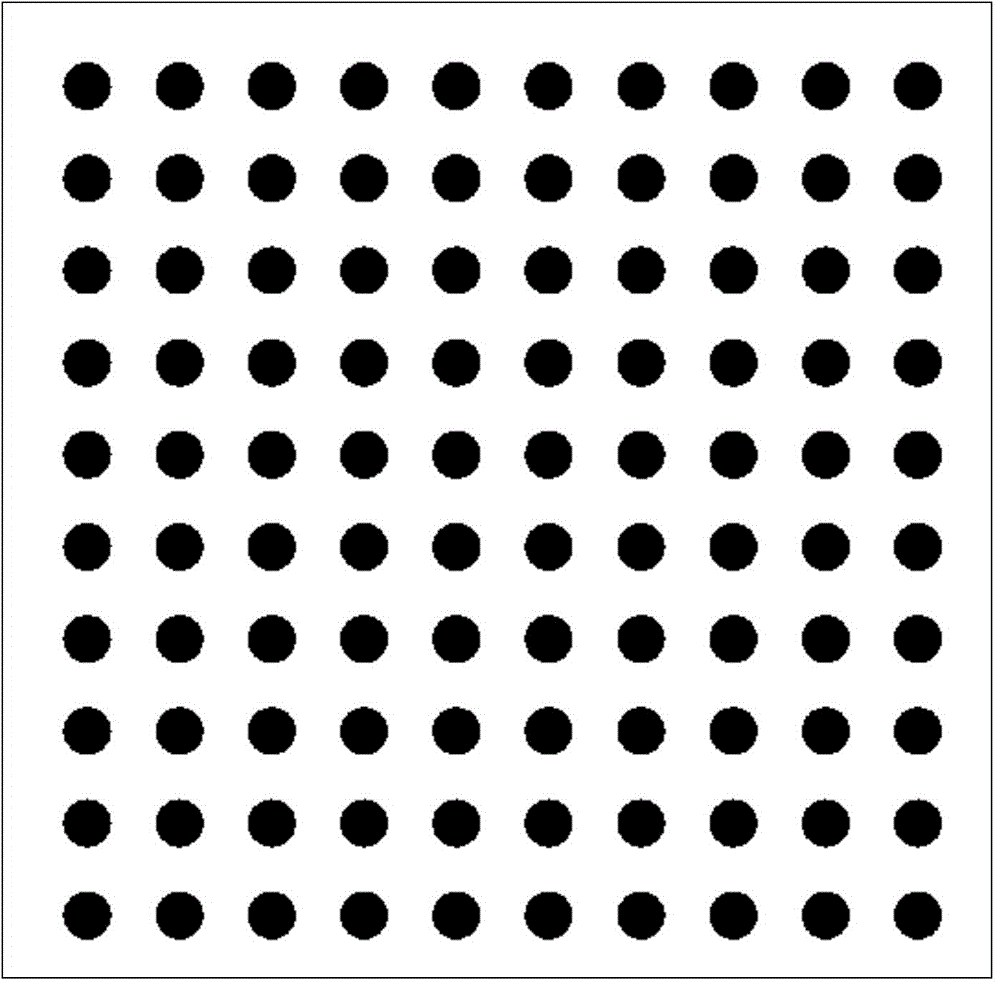

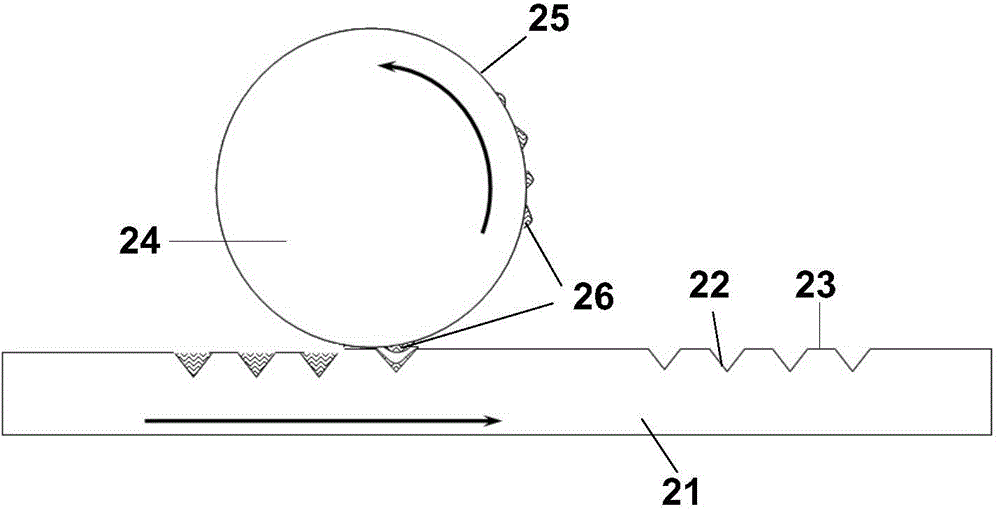

[0038] The commercial transparent polyethylene naphthalate (PEN) that has been cleaned before leaving the factory is cut into a substrate of 120×200mm, and after removing the covering protective film, the main component is directly printed on its surface by gravure printing equipment. Gravure printing ink of acrylic resin, the local cell layout of the flat gravure plate used in the equipment is as follows figure 1 shown. Wherein the diameter of the mesh hole remains unchanged, and the optimal value is taken in the range of 40-60 microns; the depth of the mesh hole is preferably in the range of 8-15 microns, and three different values can be designed according to the requirements of the optical path design, so that The obtained microlenses have different sizes to ensure the ideal optical effect of the entire array. The speed of the whole gravure printing is 5-10 m / min, the pressure between the gravure roller and the transparent PEN is 80-120 Newton, the principle is as follo...

Embodiment 2

[0041]The commercial high-transmittance glass that has been cleaned before leaving the factory is used as the substrate, and the main components are printed on the glass surface by first printing on the rubber roller and then transferring to the glass by using a 300 mm wide roll-type indirect gravure printing equipment It is a gravure printing ink of transparent polyacrylic resin, and the speed of indirect gravure printing is 3-7 m / min. The diameter of the cells on the gravure roller used is 60-90 microns, and the depth is 10-20 microns. Among them, the diameter of the cell is designed with three different values according to the requirements of the optical path design, and the depth of the cell takes the same optimal value.

[0042] The glass sample obtained by printing stays in a vacuum environment at 180°C and an air pressure of 2-5kPa for 3-5 minutes, so that the transparent polyacrylic resin in the printing ink (melting point temperature is less than 120°C, in a viscous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com