Aluminizing and inlay casting technology for Al-based material

An aluminum-based material and aluminized technology, which is applied to engine components, pistons, mechanical equipment, etc., can solve problems such as melting of aluminum-based materials, and no metallurgical bonding surface between aluminum-based materials and aluminized materials. Promote the use and improve the effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

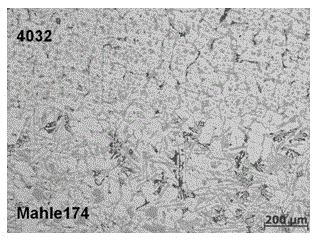

Image

Examples

Embodiment 1

[0041] An aluminizing and embedded casting process for aluminum-based materials, including selection of aluminized materials and surface activation treatment of aluminum-based materials, and after the selection of aluminized materials and surface activation treatment of aluminum-based materials, aluminizing and embedded casting are also included;

[0042] The selection of the aluminized material refers to selecting the aluminized material according to the aluminum-based material, and the melting point of the aluminized material is lower than that of the aluminum-based material;

[0043] The surface activation treatment of the aluminum-based material includes the following steps in sequence: first, the surface of the aluminum-based material is shot blasted, and then the aluminum-based material is ultrasonically cleaned, and then the aluminum-based material is soaked in a sodium hydroxide solution, and then the aluminum-based material is The base material is taken out, cleaned an...

Embodiment 2

[0046] Basic content is the same as embodiment 1, the difference is:

[0047] In the aluminizing and embedded casting, after the aluminizing material is melted, the molten aluminizing material is refined, degassed and slag removed, and then the molten aluminizing material is kept warm;

[0048] In the aluminizing and embedded casting, the holding temperature of the aluminized material melt is 10°C higher than the melting point of the aluminized material, and the heating temperature of the aluminum-based material is 100°C lower than the melting point of the aluminum-based material;

[0049] In the aluminizing and embedded casting, placing the aluminum-based material in the aluminized material melt and vibrating the aluminum-based material up and down refers to: placing the aluminum-based material in the aluminized material melt and making the aluminum-based material vibrate 50 mm, up and down reciprocating motion at a frequency of 1 Hz, after 30 to 60 seconds, take out the alum...

Embodiment 3

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] The melting point of the aluminized material is 10°C lower than that of the aluminum-based material;

[0053] In the surface activation treatment of the aluminum-based material, first, the surface of the aluminum-based material is shot-peened with a steel shot having a diameter of 2 mm, so that the surface roughness of the aluminum-based material is greater than or equal to 6 microns, and then the aluminum-based material is ultrasonically After cleaning, the aluminum-based material is soaked in a 20% sodium hydroxide solution at a temperature of 80°C for 5 to 10 minutes to remove the aluminum oxide layer on the surface of the aluminum-based material, and then the aluminum-based material is removed from the sodium hydroxide solution. The aluminum-based material is taken out from the solution and cleaned with pure water, and then the aluminum-based material is dried and placed in a vacuum bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com