Industrial control type automatic network communication protocol converter and communication protocol conversion method

An automation network and communication protocol technology, which is applied in the field of industrial control automation network communication protocol converter and communication protocol conversion, can solve the problems of slow transmission rate, high bit error rate, and inflexibility, and achieve high communication reliability and flexible implementation The effect of preventing data frame overlap or omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

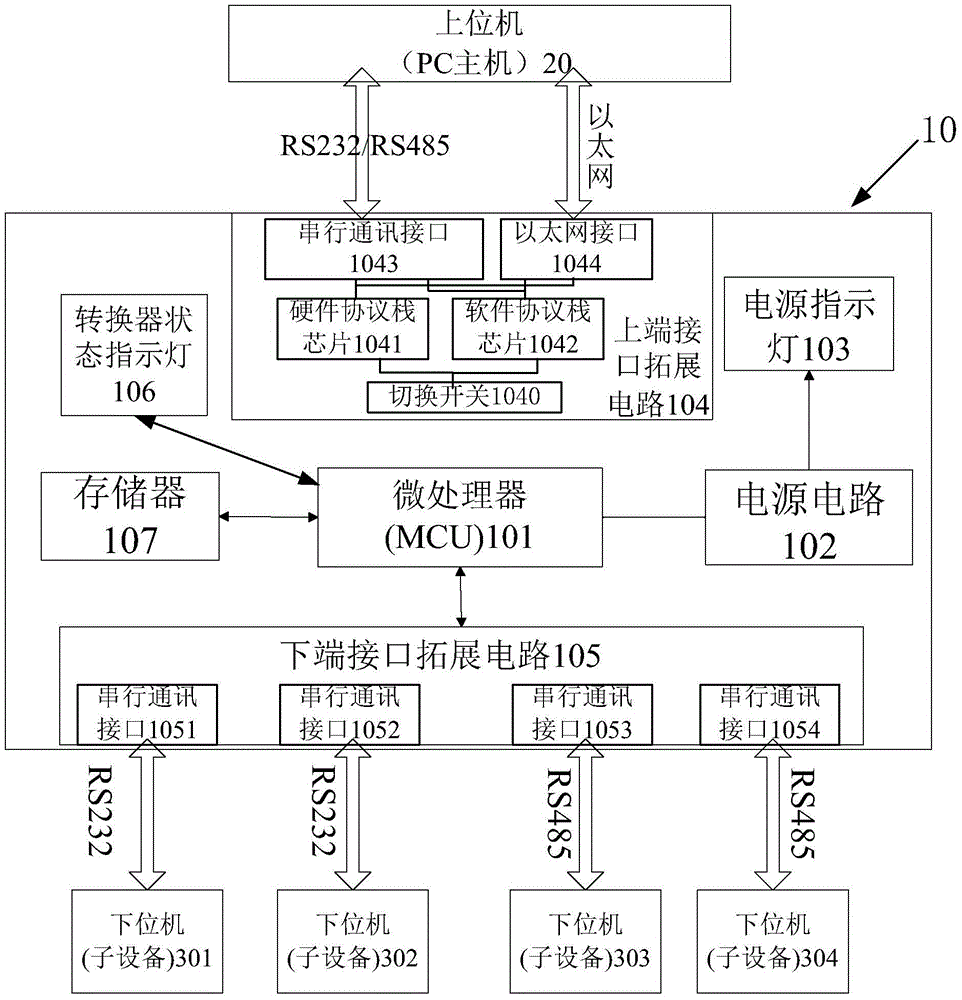

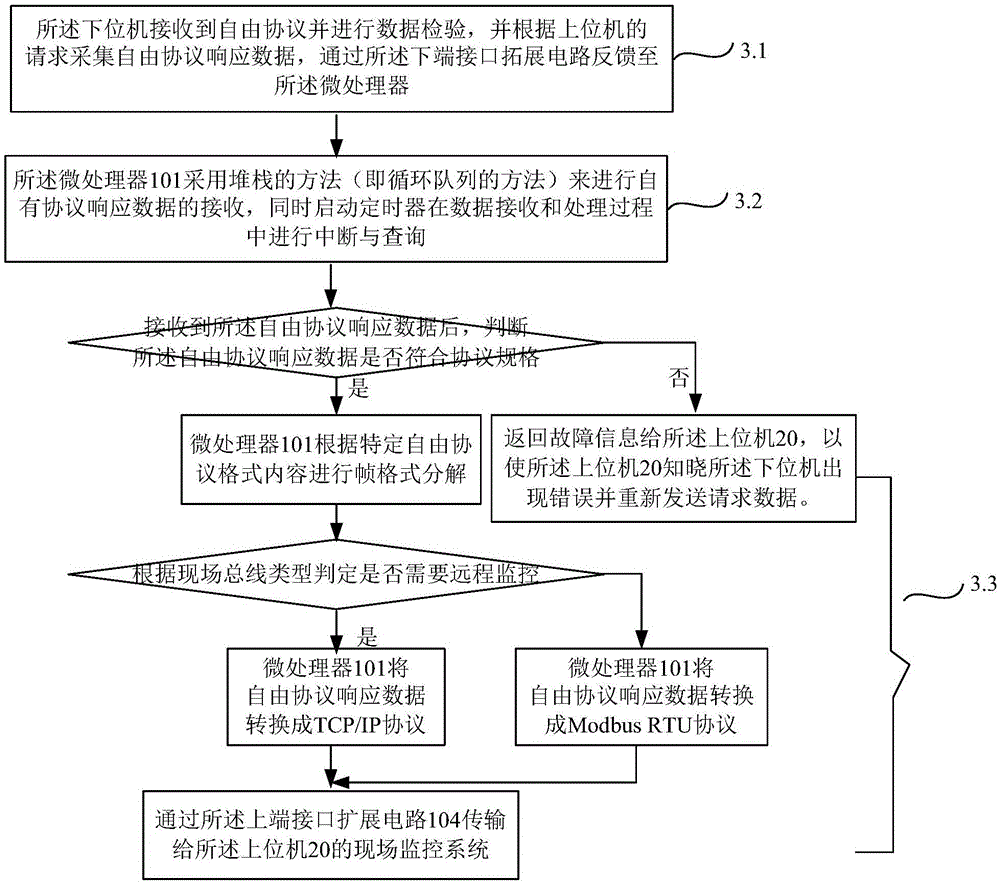

[0035] Please refer to figure 1 , the present embodiment provides an industrial control automation network communication protocol converter 10, including: a microprocessor (MCU) 101 and a power circuit 102 connected to the microprocessor 101, a power indicator light 103, and an upper interface expansion circuit 104 , a lower end interface expansion circuit 105 , a converter status indicator light 106 and a memory 107 .

[0036] Wherein, the microprocessor 101 and the upper interface expansion circuit 104 are the core devices of the industrial control automation network communication protocol converter 10 of this embodiment, and the microprocessor 101 is the core device of the entire industrial control automation network communication protocol converter 10 The control center adopts STM32F103 series chip, which includes Ethernet MAC layer controller, CAN controller and USART serial interface, supports Ethernet, CAN bus, RS231 bus and RS485 bus expansion, and can complete informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com