Rapid annealing preparation method of Al-Si<+> ohmic contact electrode

A technology of rapid annealing and ohmic contact electrodes, which is applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problem of weakening the influence of work function on ohmic contact, achieve efficient and rapid preparation, simple equipment, needle The effect of fewer holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

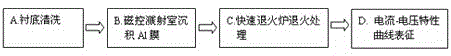

[0017] figure 1 The operation process of middle embodiment A is as follows:

[0018] 1. Ultrasonic for 5 min at room temperature with analytical grade acetone, rinse with deionized water. Repeat this step 3 times.

[0019] 2. Sonicate with absolute ethanol at room temperature for 5 min, and rinse with deionized water. Repeat this step 3 times.

[0020] 3. Concentrate H first 2 SO 4 (98%): H 2 O 2 =2:1 mixed solution, boil for 3-5min, rinse with deionized water for 2-3 times, then use HF(10%):H 2 Soak in the mixed solution of O=1:10 for 30s and rinse with deionized water for 2-3 times.

[0021] 4. Concentrate HNO first 3 Boil for 3min, rinse 2-3 times with deionized water, then use HF (10%):H 2 Soak in the mixed solution of O=1:10 for 30s and rinse with deionized water for 2-3 times. Repeat this step 2 times.

[0022] 5. Concentrate HNO fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com