Preparation method of LaNiO<3> submicron microsphere electrode material with hollow structure

An electrode material, sub-meter technology, applied in chemical instruments and methods, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., to achieve good structural stability, long cycle life, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of LaNiO 3 Precursor

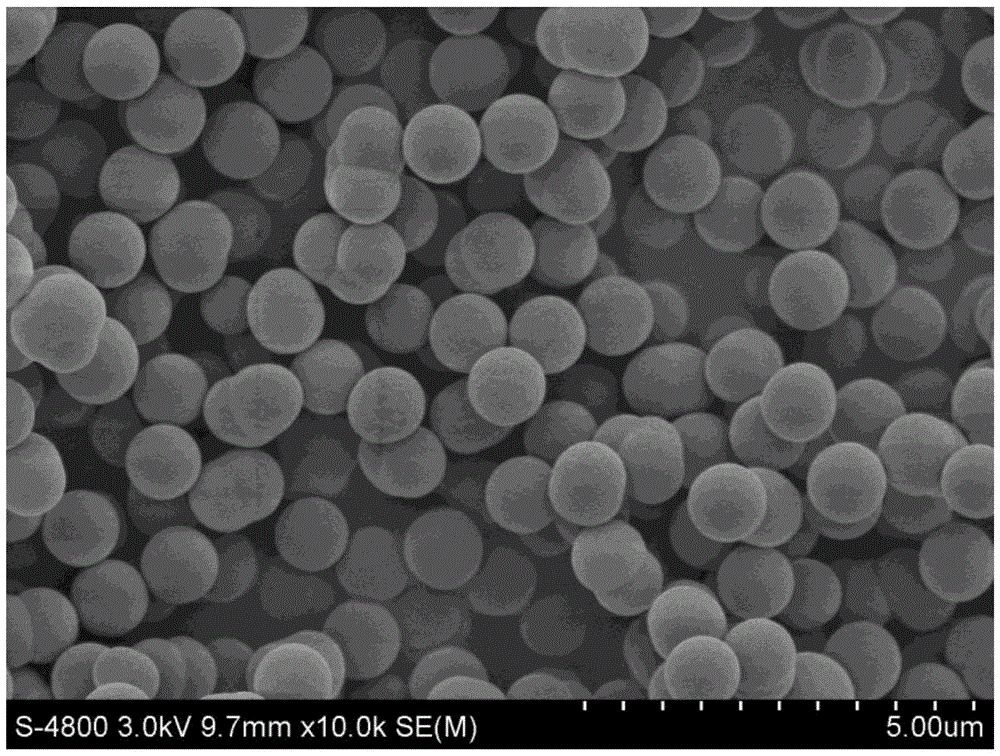

[0037] Weigh 0.4330gLa(NO 3 ) 3 9H 2 O, 0.2910gNi(NO 3 ) 3 ·6H 2 O was dissolved in 160ml of isopropanol solution, then 40ml of glycerin was added and stirred for 5 minutes. The stirred solution was transferred to a 200ml hydrothermal kettle and placed in an oven at 180°C for 6 hours, and then naturally cooled to room temperature after the reaction. The synthesized precursor was separated with a centrifuge and washed with ethanol for 3 to 4 times, and dried in an oven at 70°C for no less than 12 hours. The SEM image of the dried sample (instructions attached figure 1 ) has a highly uniform spherical structure and its size ranges from 800 to 1000 nm. .

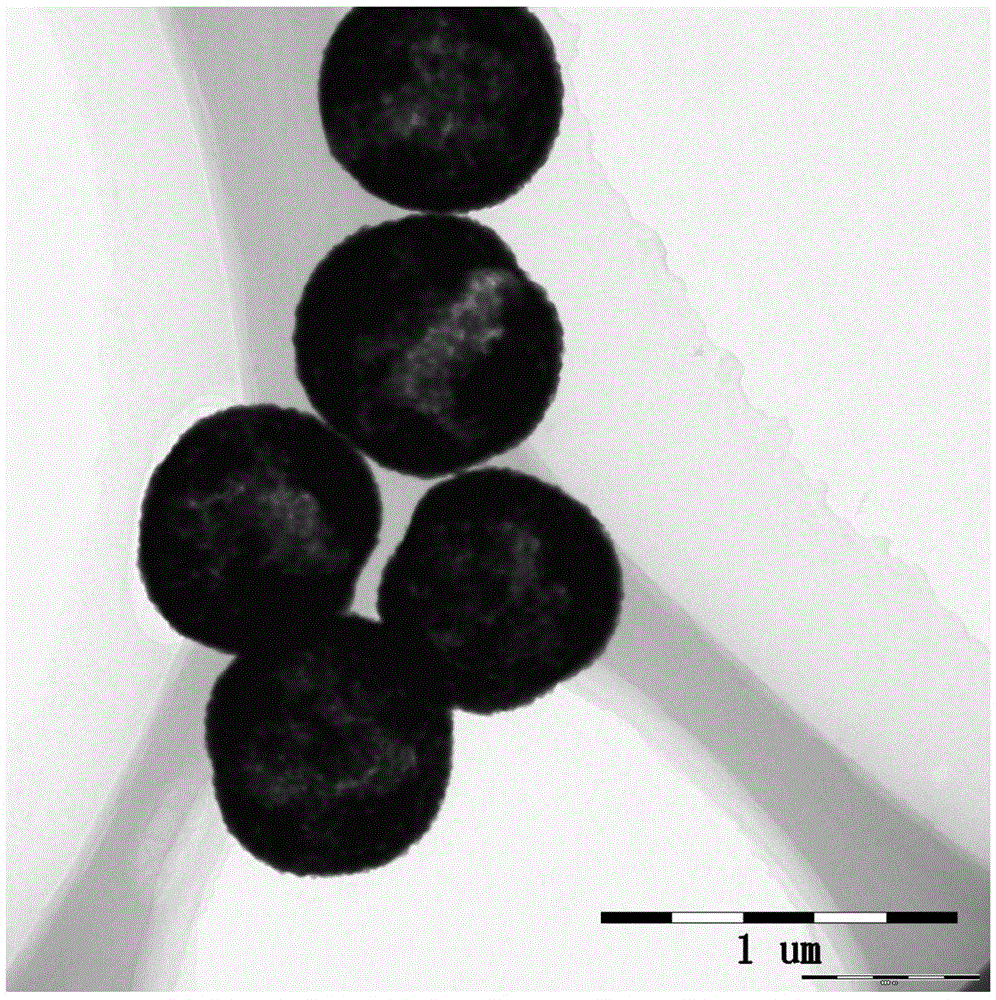

[0038] (2) Heat treatment of LaNiO 3 Preparation of LaNiO with Hollow Structure from Precursor 3 Submicron sphere

[0039] Will get LaNiO 3The precursor was heat-treated in air, the heat-treatment temperature was 600°C, the heat-treatment time was 6 hours, and the heat...

Embodiment 2

[0043] (1) Preparation of LaNiO 3 Precursor

[0044] Weigh 0.4330gLa(NO 3 ) 3 9H 2 O, 0.2910gNi(NO 3 ) 3 ·6H 2 O was dissolved in 160ml of isopropanol solution, then 40ml of glycerin was added and stirred for 5 minutes. The stirred solution was transferred to a 200ml hydrothermal kettle and placed in an oven at 180°C for 6 hours, and then naturally cooled to room temperature after the reaction. The synthesized precursor was separated with a centrifuge and washed with ethanol for 3 to 4 times, and dried in an oven at 70°C for no less than 12 hours.

[0045] (2) Heat treatment of LaNiO 3 Preparation of LaNiO with Hollow Structure from Precursor 3 submicron spheres.

[0046] Will get LaNiO 3 The precursor was heat-treated in air, the heat-treatment temperature was 600°C, the heat-treatment time was 10 hours, and the heating rate was 1°C / min.

[0047] (3) Preparation of LaNiO 3 working electrode

[0048] LaNiO with a hollow structure as the active material 3 The sub...

Embodiment 3

[0050] (1) Preparation of LaNiO 3 Precursor

[0051] Weigh 0.4330gLa(NO 3 ) 3 9H 2 O, 0.2910gNi(NO 3 ) 3 ·6H 2 O was dissolved in 160ml of isopropanol solution, then 40ml of glycerin was added and stirred for 5 minutes. The stirred solution was moved to a 200ml hydrothermal kettle and placed in an oven at 120°C for 6 hours of reaction, and then naturally cooled to room temperature after the reaction. The synthesized precursor was separated with a centrifuge and washed with ethanol for 3 to 4 times, and dried in an oven at 70°C for no less than 12 hours.

[0052] (2) Heat treatment of LaNiO 3 Preparation of LaNiO with Hollow Structure from Precursor 3 submicron spheres.

[0053] Will get LaNiO 3 The precursor was heat-treated in air, the heat-treatment temperature was 600°C, the heat-treatment time was 10 hours, and the heating rate was 1°C / min.

[0054] (3) Preparation of LaNiO 3 working electrode

[0055] LaNiO with a hollow structure as the active material 3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com