Method for calculating safe value of CO concentration at outlet of coal mill

A calculation method and coal mill technology, applied in the field of safe operation of coal mills and boiler auxiliary equipment, can solve the problem of inability to sensitively reflect temperature changes in local areas, reduce air preheater efficiency, and fail to take into account the safety value of the pulverizing system Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

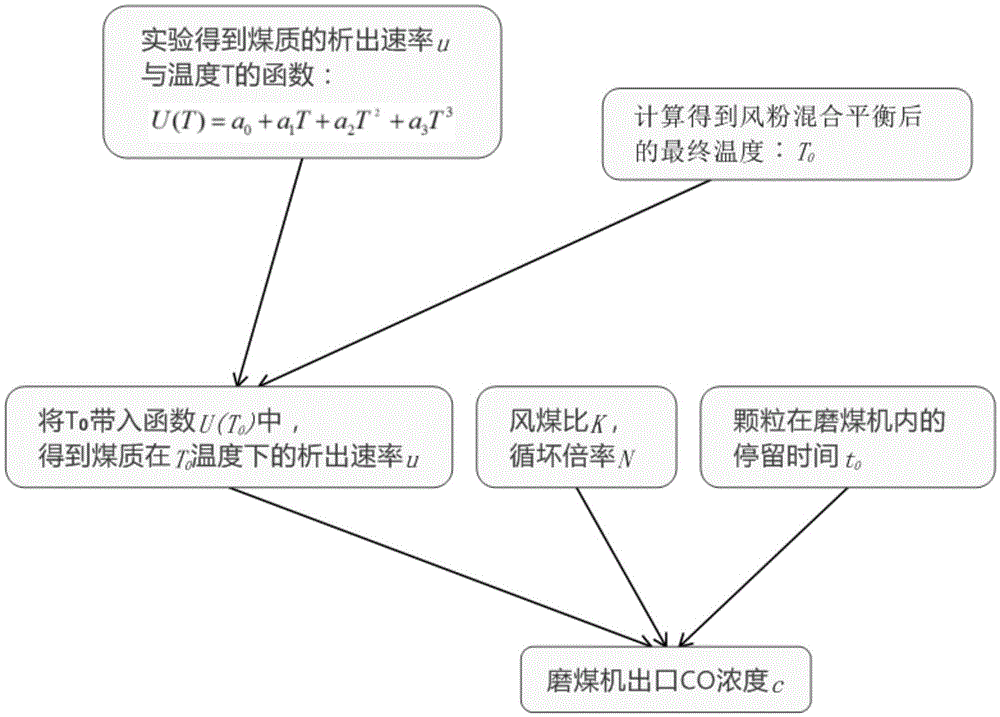

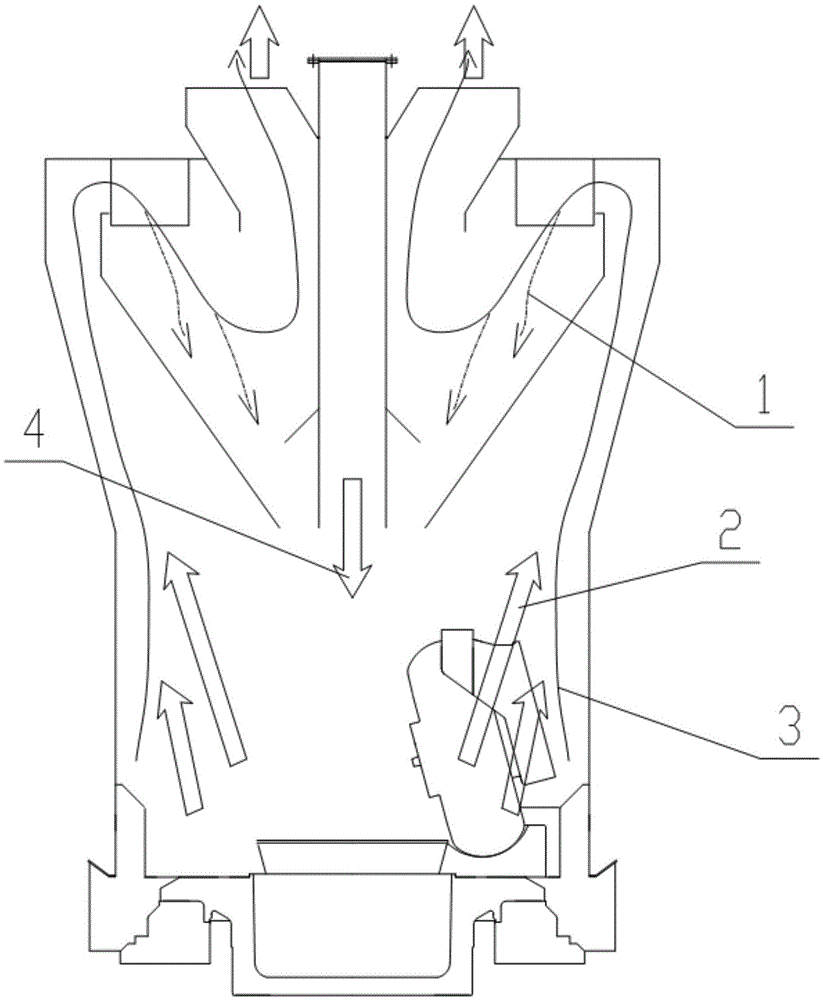

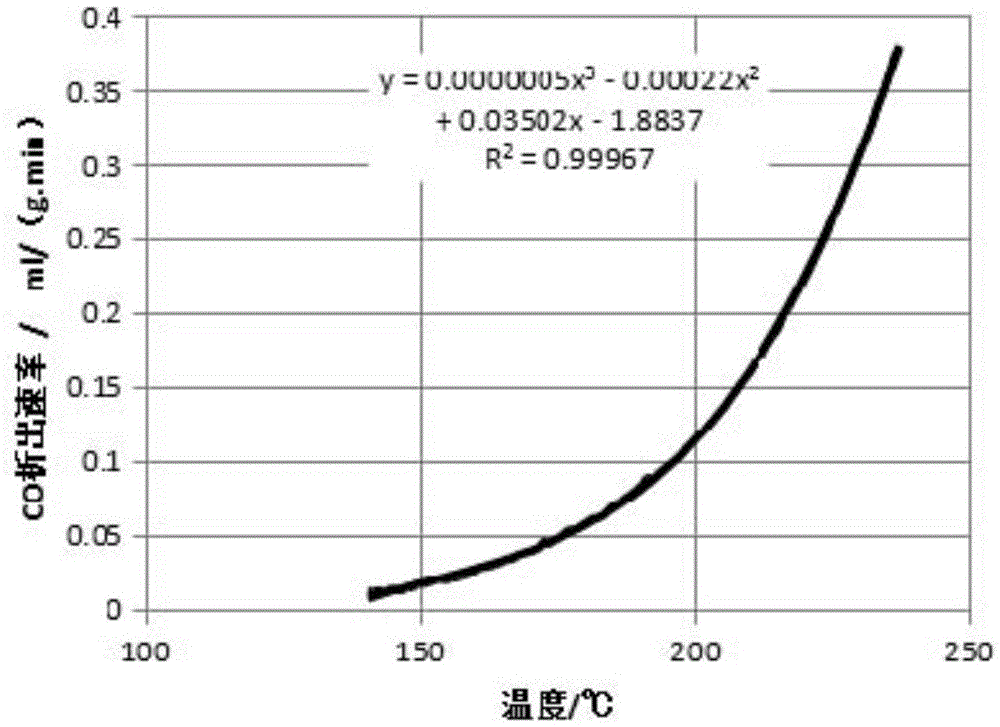

[0045] 2. If figure 1 Shown are the steps of the calculation method of the present invention. Firstly, through the experiment of CO precipitation characteristics of coal (the experiment generally adopts the infrared-thermograviation experiment of coal), the corresponding relationship between the temperature of the coal quality and the precipitation rate is obtained, and it is fitted into a certain form of functional relationship, so that Subsequent calculations; then use the parameters before mixing the wind powder, including the wind temperature T h , coal temperature T c , air volume Q and powder volume M, combined with air specific heat C ph and dry coal specific heat C pc Two physical constants, calculated to obtain the final temperature T after the air powder is mixed and balanced 0 ; find T 0 Then, bring it into the fitting function U(T) obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com